I FOUND THE WEBER FOR RIGHT AT $200

THE "DGEV" I HAD CAME WITH AN ADAPTER TO FIT AN AMC INTAKE MANIFOLD. IT WAS A PROGRESSIVE CARB, MEANING IT WAS ACTUALLY A ONE BARREL THAT OPENED UP INTO A 2 BARREL AS YOU PUSHED YOUR ACCELERATOR 3/4 OF THE WAY AND MORE

I SPENT AN ADDITIONAL $200 OR SO FOR JETS AND AIR DEALEES AND SPENT OVER A YEAR ATTEMPTING TO MAKE IT WORK CORRECTLY, I SPOKE TO MANY PEOPLE AND KEPT RECORDS ON MILEAGE, I DID SO MANY PLUG CUTS, I THOUGHT I WOULD WEAR OUT THE PLUG HOLES. AFTER STRIPPING OUT 2 OF THE CARBS SCREWS, I GAVE UP ON IT.

I WON SOME $$$ IN THE LOTTERY AND SPENT IT ALL ON AN OFFENHAUSER 4 BBL INTAKE, AND A HOLLEY 390 CFM. IF I RECALL CORRECTLY, OVER $600 TO BEGIN WITH.I INSTALLED AN O2 SENSOR IN MY EXHAUST INCHES PAST MY HEADMAN HEDDERS. AT 1ST I TRIED A VOLTMETER, AND NOT TOO MUCH LATER I BOUGHT A CRAPPY AIR/FUEL GAGE, FOLLOWED BY A NICER ONE (THIS GAUGE WAS ABOUT $80).

USING THE A/F GAUGE, I NO LONGER HAD TO DO PLUG CUTS, AS "LEAN"--"STOICH"--"RICH" WERE NOW DISPLAYED AS RED-YELLOW-GREEN LEDs. I WAS ABLE TO "JET" MY CARB FOR THE WAY I DRIVE AND USING MY "ON DASH" VACUUM GAUGE I SELECTED THE CORRECT POWER VALVE.

NEITHER THE WEBER OR THE HOLLEY WERE "CORRECT" STRAIGHT OUT OF THE BOX. IN FACT, BOTH RAN "LEAN". THE "O2 METHOD" MAY HAVE HELPED W/ THE WEBER'S JETTING IF I HAD KNOWN ABOUT THE METHOD. IT'S NOW WATER UNDER THE BRIDGE, I'M A HOLLEY KINDA GUY NOW, AND ALL OF IT'S PARTS ARE AVAILABLE LOCALLY.

I REALLY THINK IN THE LONG RUN, THE '79 BBD IS GONNA BE THE "WISE WAY" AND THE LESSER "PAIN IN THE BUTT" FIX. AS WELL AS CHEAPER. JUST ASK RICK!

WE CAN GET THIS CHEAPER!

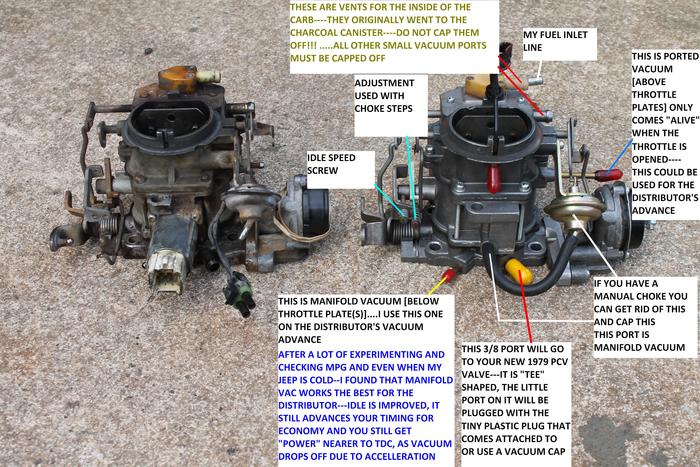

TAKE THE PLUG OFF OF THE BACK OF THE CARB, LEAVE IT OFF

WHAT WE CAN TRY FOR NOW IS TO REMOVE THE SOLENOID DEALEE THAT THAT INCREASES THE IDLE SPEED, REMOVE THE WHOLE BRACKET OFF OF THE CARB. RE-INSTALL THE SCREWS

DIS-CONNECT THE WIRES, PLUG/CAP THE VACUUM LINE

USE THIS '79 AS A GUIDE (PIC) PLUG CAP ALL VACUUM LINES EXCEPT FOR PCV AND VACUUM ADVANCE TO CARB (BOTH ARE AT BOTTOM, AND FACING YOU). MAIN THING IS, EVERYTHING NOT USED IS CAPPED OFF, DOING THIS MAY ELIMINATE UNKNOWN VACUUM LEAKS ALSO

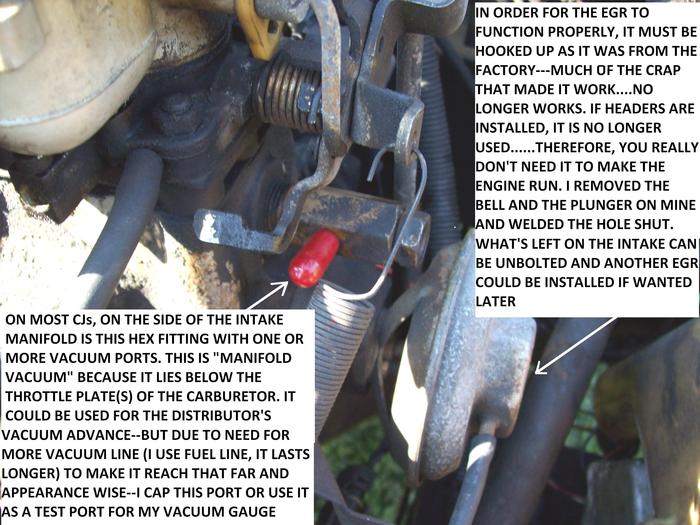

2ND PIC IS INTAKE MANIFOLD, REMOVE ALL VACUUM LINES AND CAP THE PORTS

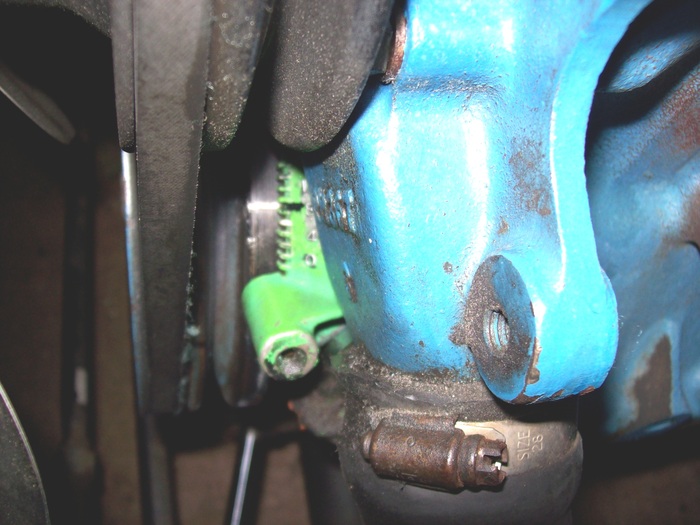

LETS TIME THIS PUPPY NOW. TEMPORARILY REMOVE THE VACUUM ADVANCE FROM THE DISTRIBUTOR AND SHOVE A BOLT IN THE HOSE (SEE PIC 3)

HOOK UP YOUR DWELL/ TACH GET THE IDLE TO 680----KEEP IT THERE AS YOU TIME

WHEN YOU FINISH YOU SHOULD BE SEE THIS IN YOUR LIGHT, EVERY TIME IT FLASHES (THIS IS 9 DEGREES BTDC, IN MY 3RD PIC) 8 OR 10 IS OK. WHITE CHALK CORRESPONDS WITH BLACK LINE. YOU ARE AT 680 RPM

NOW LETS HOOK UP THE VACUUM ADVANCE HOSE BACK UP TO THE DISTRIBUTOR----NOW ADJUST IDLE BACK TO 680 RPM (IT WILL GET FASTER, WHEN HOOKED BACK UP TO MANIFOLD VACUUM)

WHEN YOU GET TO THIS POINT---I WILL TALK YOU THRU CHECKING YOUR MECHANICAL AND VACUUM ADVANCE TO INSURE THEY WORK, USING THE TIMING LIGHT

THE MEDIC

Images (Click to make bigger)

Thursday, June 21st, 2012 AT 4:10 AM