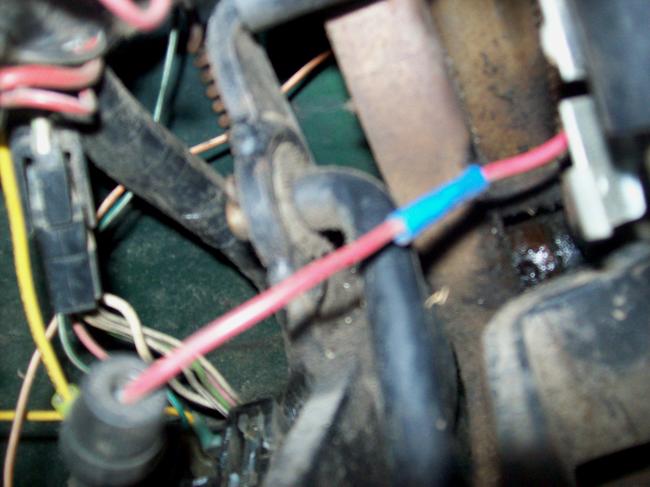

I tried your link yesterday and did not work. I actually got bored earlier and decided what the hell. If I have a fire the boat fire extinguisher was near. I did some deductive reason and figured the jumper should be hooked to the field 2 post and brown to the other.

After hooking it up I tested and with engine off I had 12.5 to 12.7 after multiple attempts so that is good.

While running it was only putting out like 13.3 to 13.7.

After driving around for sometime (approx 30 mins around the neighborhood) I stopped and turned off the engine to check the battery to see if I was draining and it still was maintaining at 12.5.

Should I be concerned about the low output with the alternator but what is weird is that I took the alternator off like a week ago to have it checked at O'reillys and they showed it within spec.

I appreciate your input on the plug. I looked today at all the stores for a Ford style knowing it was a ford alternator. All I came up with was the G, style.

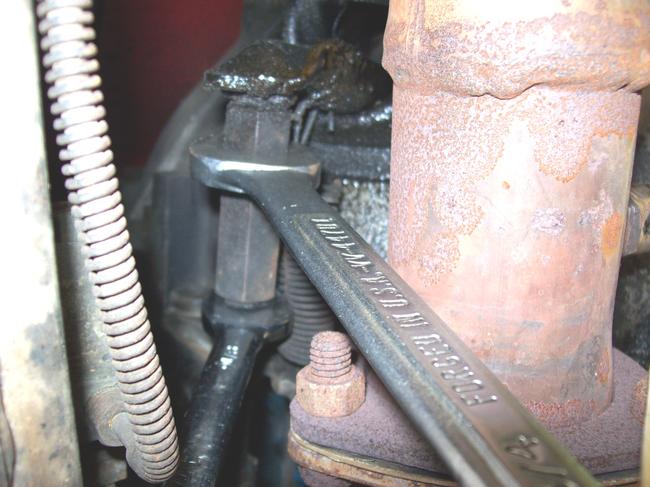

Have you had any luck finding barb fuel fittings for the fuel pump. I had to buy a metal brake line cut a 2 1/2 inch section then got 1 ft 1/2 of rubber fuel line hose to fix where the old metal lines ferrell was leaking at the top of the fuel pump. It is not the prettiest work but it works and no leaks!

Also you said you know some great places to get some part. Where might those be? I know as of right know I need.

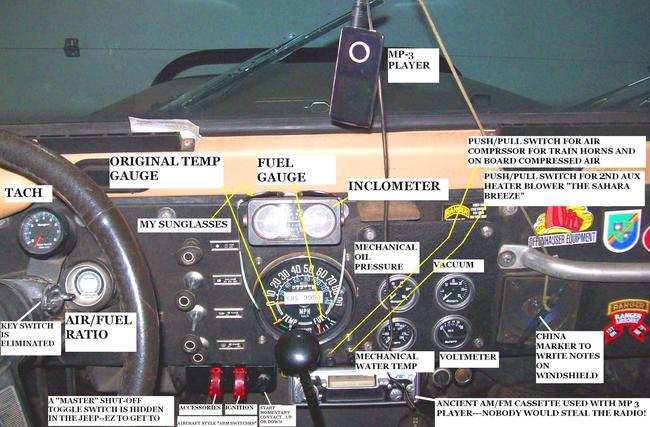

-fuel gauge not working (could be something in the tank or gauge)

-Volt meter gauge not working.

-Need the boots for shifters, steering column through firewall, Cluch pedal boot through firewall.

-I feel like the clutch linkage is a little sloppy where it connects to the mount on the transmission.

-may need new seats (will depend if I can get the slides and tilts to break free.) I did get the passenger side to lift but not slide forward so there is still hope with lots of lubricant!

-Also been trying to find a good top that has the removable windows (not a tiger top). If you know a good place to find a hardtop, I would love to hear that. I have been reading on converting a CJ7 to fit the CJ5 but have not decided to pull the trigger. Also found a really cool one where a guy used heavy foam and shaped it then fiberglass mat and resined it to make a hard top.

I also did find a small crack on the bottom of the bell housing maybe 1 1/2 inch long. It is on the flat where the engine bolt to the transmission. I am not to concerned seeing that area does not have fluid storage only covers shields the clutch and such.

Well I am sure the parts list will grow.

Thank you

Joe

Was this helpful?

Yes

No

Sunday, August 9th, 2015 AT 6:57 PM