Hi,

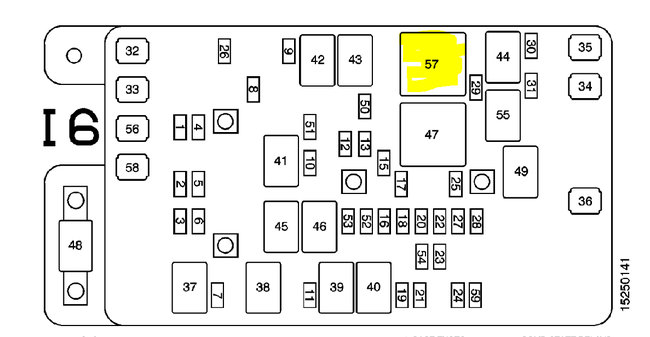

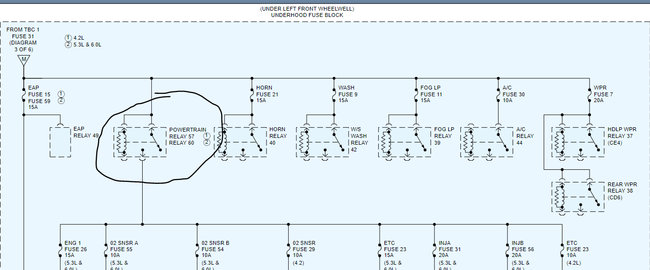

Okay. Then we need to start checking. Here is a list of how the TAC system works. Let me know where you would like to start and I start looking through diagnostic flow charts and send them to you as well.

___________________________________________________

2007 Chevy Truck TrailBlazer 2WD L6-4.2L

Throttle Actuator Control (TAC) System Description

Vehicle Powertrain Management Computers and Control Systems Electronic Throttle Actuator Description and Operation Components Throttle Actuator Control (TAC) System Description

THROTTLE ACTUATOR CONTROL (TAC) SYSTEM DESCRIPTION

Throttle Actuator Control (TAC) System Description

Throttle Actuator Control (TAC) Overview

The throttle actuator control (TAC) system uses vehicle electronics and components to calculate and control the position of the throttle blade. This eliminates the need for a mechanical cable attachment from the accelerator pedal to the throttle body. This system also performs the cruise control functions as well.

The TAC system components include, but are not limited to the following:

* The accelerator pedal position (APP) sensors

* The throttle body

* The powertrain control module (PCM)

Each of these components interface together to ensure accurate calculations and control of the throttle position (TP).

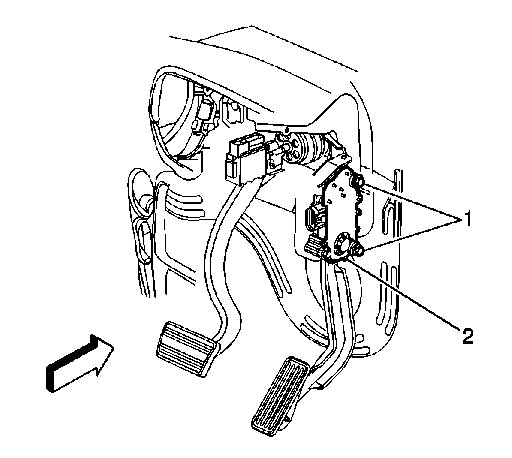

Accelerator Pedal Position (APP) Sensor

The APP sensor is mounted on the accelerator pedal assembly. The APP is actually 2 individual APP sensors within 1 housing. There are 2 separate signal, low reference, and 5-volt reference circuits. APP sensor 1 voltage increases as the accelerator pedal is depressed. APP sensor 2 voltage decreases as the accelerator pedal is depressed.

Throttle Body Assembly

The throttle body for the throttle actuator control (TAC) system is similar to a conventional throttle body with several exceptions. One exception being the use of a motor to control the throttle position instead of a mechanical cable. Another exception is the throttle position (TP) sensor. The TP sensor is mounted in the throttle body assembly. The TP sensor is 2 individual TP sensors within the throttle body assembly. Two separate signal, low reference, and 5-volt reference circuits are used to connect the TP sensors and the powertrain control module (PCM). TP sensor 2 signal voltage increases as the throttle opens. TP sensor 1 signal voltage decreases as the throttle opens.

Modes of Operation

Battery Saver Mode

If the powertrain control module (PCM) detects the ignition ON for 10 seconds without the engine running, the PCM will allow the throttle blade to return to the default position. This removes the draw that is present while holding the throttle blade at the calculated idle position.

Reduced Engine Power Mode

When the PCM detects a problem with the throttle actuator control (TAC) system the PCM enters one of the following Reduced Engine Power Modes:

* Acceleration Limiting-The control module will continue to use the accelerator pedal for throttle control, however the vehicle acceleration is limited.

* Limited Throttle Mode-The control module will continue to use the accelerator pedal for throttle control, however the maximum throttle opening is limited.

* Throttle Default Mode-The control module will turn off the throttle actuator.

* Forced Idle Mode-The control module will perform the following actions:

- Limit engine speed to idle by positioning throttle position, or by controlling fuel and spark if throttle is turned off.

- Ignore accelerator pedal input.

* Engine Shutdown Mode-The control module will disable fuel and de-energize the throttle actuator.

Wednesday, January 1st, 2020 AT 10:10 PM