Hi,

Did it start working after you replaced the ASD? If it did, recheck to see if there is corrosion, a damaged pin (pushed in), pull the ASD out and put it back in and see if it changes.

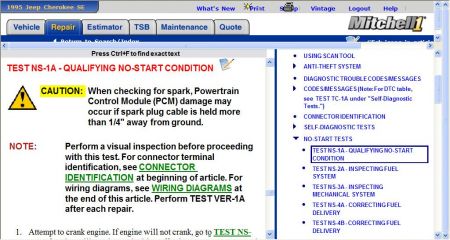

Also, there is an ignition ballast resistor relay. Check it as well. It is located under the hood on the outside of the power distribution box. See pic 1 You can use the aforementioned link to test a relay for this one as well.

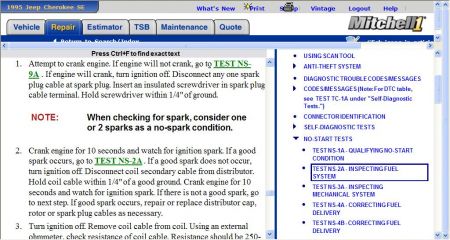

The PCM controls ignition timing and coil dwell by controlling the ground path to the ignition coil. So the idea that you have power to the coil on one wire is normal. See pic 2 For power to flow, the PCM needs to provide ground.

Have you checked for diagnostic trouble codes? I have a feeling that if the ballast relay is good it may be related to the crankshaft position sensor. Follow this link and let me know if anything is stored. You can get codes without a scanner on this vehicle.

https://www.2carpros.com/articles/jeep-diagnostic-trouble-codes-for-car-built-on-or-before-1995-odb1

Next, make sure the connector to the crankshaft position sensor is good. Also, take a look through these three links:

https://www.2carpros.com/articles/how-a-crank-shaft-angle-sensor-works

https://www.2carpros.com/articles/symptoms-of-a-bad-crankshaft-sensor

https://www.2carpros.com/articles/crankshaft-angle-sensor-replacement

_____________________________________________

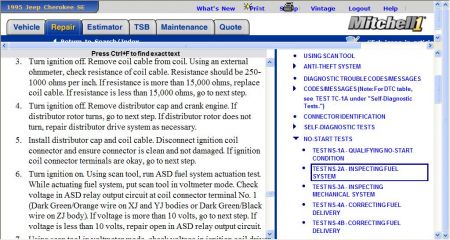

Here are the directions for testing your crankshaft position sensor. Basically, you are making sure there is no resistance between terminals B and C. See pic 3

PROCEDURE

1. Near the rear of intake manifold, disconnect sensor pigtail harness connector from main wiring harness.

See pic 3

2. Place an ohmmeter across terminals B and C (Fig. 5). Ohmmeter should be set to 1K-to-lOK scale for this test. The meter reading should be open (no resistance). Replace sensor if a low resistance is indicated.

___________________________________________

If you determine the sensor is bad, here are the directions specific to your vehicle for replacement.

I1993 Jeep Truck Cherokee 4WD L6-242 4.0L VIN S MFI

Procedures

Vehicle Powertrain Management Sensors and Switches - Powertrain Management Sensors and Switches - Computers and Control Systems Crankshaft Position Sensor Service and Repair Procedures

PROCEDURES

Crankshaft Position (CKP) Sensor 4.0L

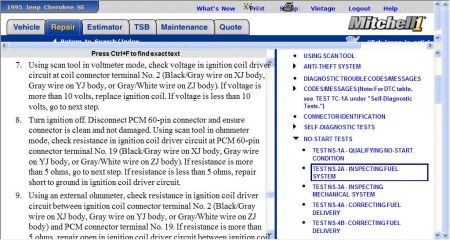

See pic 4

REMOVAL

1. Disconnect negative battery cable.

2. Disconnect sensor electrical connector, located near rear of intake manifold

3. Remove nut holding sensor wiring clip to fuel rail.

4. Remove sensor mounting bolt(s) or nuts.

5. Remove the sensor from vehicle.

6. Remove clip from sensor wiring harness.

INSTALLATION

1. Position camshaft position sensor flush against the opening in transmission housing.

2. Install sensor mounting bolts or nuts and torque to 19 Nm (14 ft-lbs).

CAUTION: On some models, two bolts are used to secure sensor to transmission. These bolts are specially machined to correctly space the sensor to flywheel. Do not attempt to install any other bolts.

3. Connect the electrical connector to the sensor.

4. Install clip on sensor wire.

5. Install clip over fuel rail stud and tighten mounting nut.

Let me know. As far as the PCM being bad, anything is possible. However, lets eliminate other common causes.

Let me know what you find.

Take care,

Joe

Images (Click to make bigger)

Saturday, April 18th, 2020 AT 9:29 PM