All Righty Then,

I’m gonna sorta explain how some of this works, it will give you a BASE, to kinda build on.

Unfortunately MOST people start at the Top and try to work in, instead of understanding how the machine works 1st, before they “GO IN”!

Some of this I will leave for you to figure out on your own, before I just “Hand It To You”!---For now how the cam works for 1 cylinder (it’s the same for the other 7 CYLINDERS, except staggered out over 360 degrees of travel, of the crank)

The cam gear is traveling at � the rate of the crank, WHY, That gives the Piston, 2 Ups and 2 Downs, for every CAM 360 Degree rotation (NOT CRANK, THE CAM)THE CAM OPENS THE VALVES AND CLOSES THEM, Each valve is opened or closed, at a correct time, while the ENGINE ROTATES 2 FULL TURNS to complete one cycle (remember the other 7, follow along doing the EXACT SAME THING at staggered intervals, ! (We just only reference the 1st one as a Calibration point) THAT’S WHY IT’S A 4 STROKE! THINK ABOUT IT!---IF YOU CANNOT GET THIS IN YOUR HEAD, DO NOT MOVE ON..... THIS IS THE MEAT ANND POTATOES OF ENGINE OPERATION!

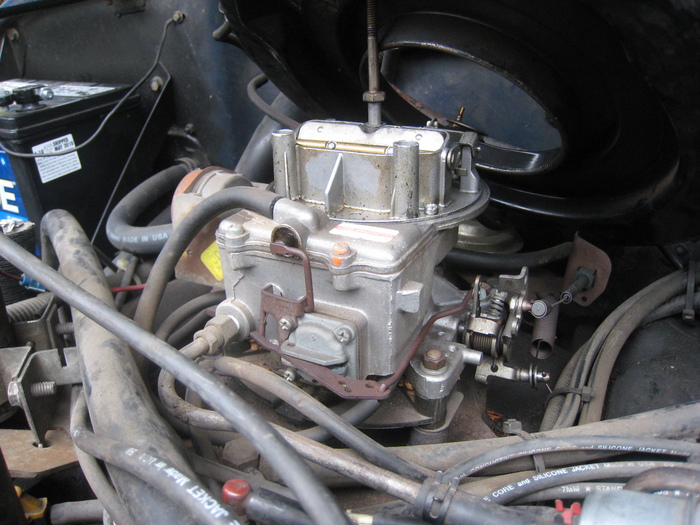

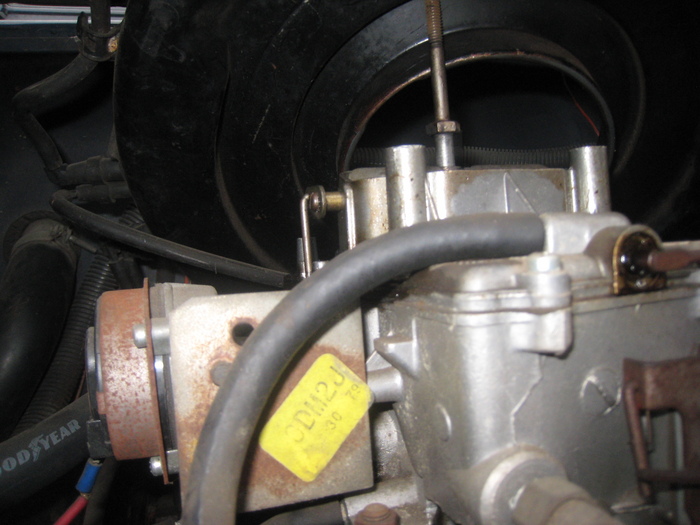

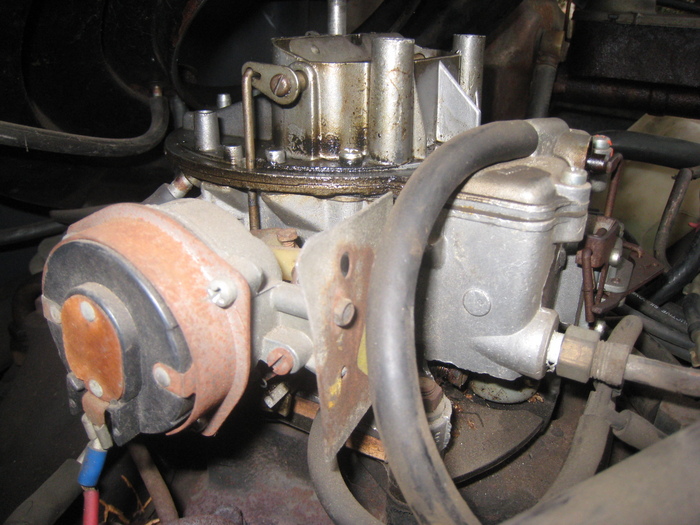

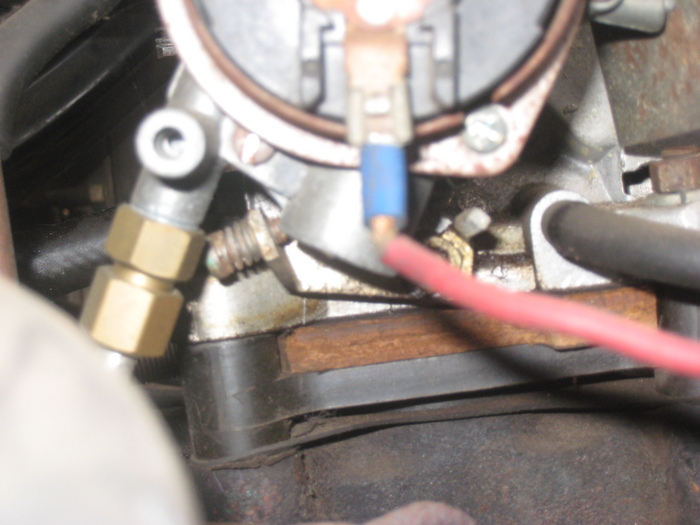

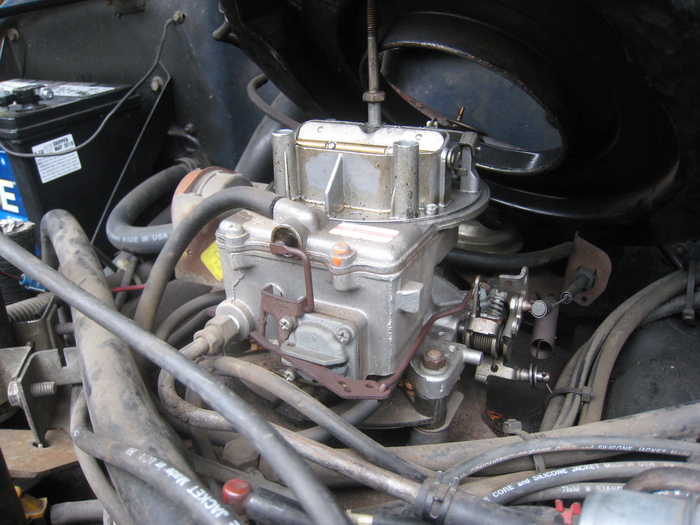

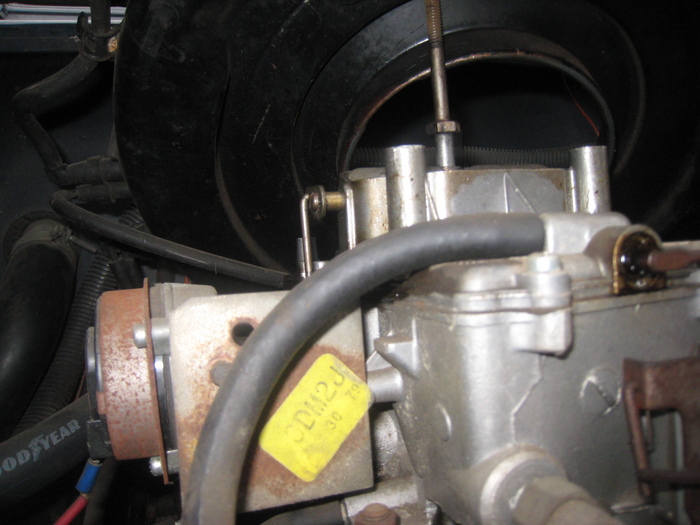

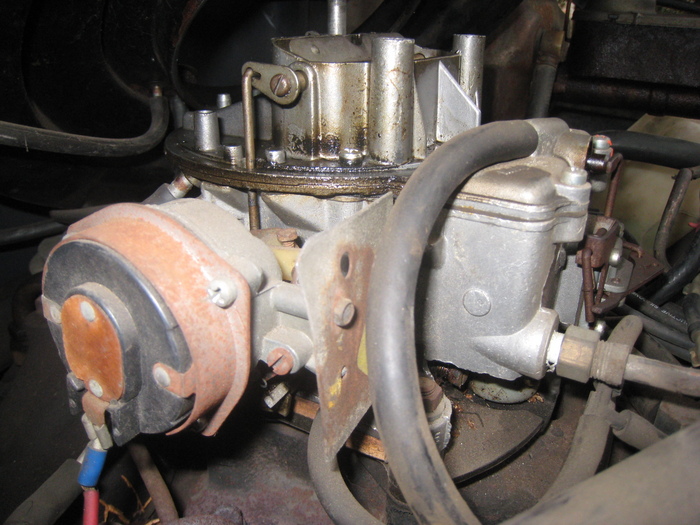

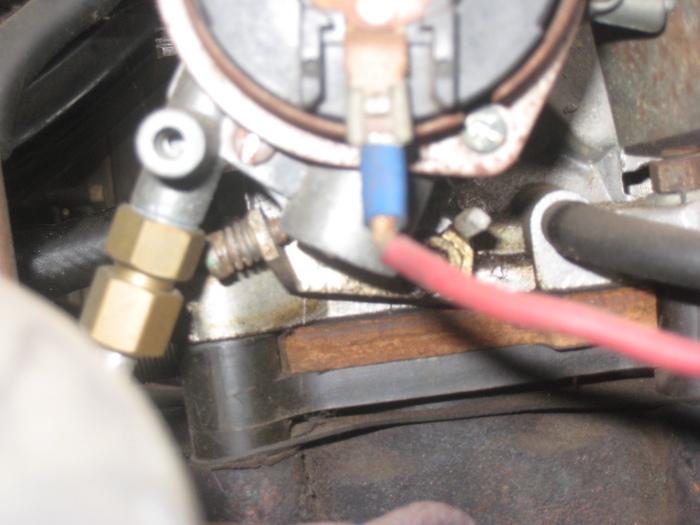

The Deal With Vaccum

All engines produce vacuum, PERFECT VAC is 30 Hg (Un-achievable man)----A WONDERFUL ENGINE, will range between 20-22 Hg (“Inches Of Mercury”, is the way you say “Hg” for everyone to understand!)..... Since its already present, Auto Engineers use it to run engine components, and other stuff too! Things like, Distributor Vacuum Advance, Warm up Doors, switches, and emission controls and other engine things, POWER BRAKE BOOSTER (if you have one), On a lot of new things, the HEATER Doors and Controls. Thank goodness a CJs Heater is all MANUAL with CABLE CONTROLS, Look in the FORUMS for the Cherokee and other “Comfort Vehicles” a lot of � em are having problems with the “AUTOMATED HEATER CRAP”. Not a “Comfort Rig” with no heat in the Dead of Winter!

4 CYCLEThis is how this works!

I will start with the POWER STROKE, The EXPLOSION just occurred the PISTON is heading down (intake and exhaust valves are closed (because of cam), THIS IS THE WHOLE REASON FOR THE ENGINE. This is the POWER or DRIVING FORCE!

In order for the system to repeat, the Power Stroke, it must do some other stuff next!

Now we got EXPLOSION WASTE to get rid of, Thus on the way back up, ONLY THE EXHAST VALVE OPENS (cam action), and the Piston pushes out the “Exhaust” into the exhaust manifold, and on out the tailpipe. THIS IS THE EXAUST STROKE!

No it’s headed down again!---The Exhaust Valve Closes, and the INTAKE VALVE OPENS (cam action), it begins SUCKING IN A PERFECTLY MIXED AIR/ FUEL MIXTURE (From Perfect Carburetor Action, WE WANT IT THAT WAY ANYWAY!)....... THIS IS WHERE THE ENGINE VACUUM COMES FROM! Cylinders doing this in rapid succession!

Next the cylinder is full, it hits bottom, The INTAKE AND EXHAUST VALVES CLOSE (cam) and the Piston starts back up..... It’s Compressing the Air/ Fuel Mix, in an “Air Tight Cylinder” (to make a good, powerful Explosion!) THIS IS THE COMPRESSION STROKE!

Now this is the part that is tricky!

Hear me thru!

When the piston reaches the EXACT TOP (TDC), and STARTS DOWN (After Top Dead Center, ATDC)� THE SPARK PLUG IGNITES THE MIXTURE and POWER STROKE BEGINS AGAIN!

BUT WHY?---WE GOT IT FIRING AT 8 BTDC!HOW CAN THAT BE.

Well if the ACTUAL EXPLOSION took place before TDC, the engine would want to ATTEMPT TO RUN BACKWARDS! (This situation is also called “Detonation” or “PINGING” (which sounds like a ball peen hammer on an anvil) It’s actually the explosion hammering on the Piston, Rod, and crank, as its really wanting to go backwards... This occurs when you are timed TOO MUCH BTDC. The explosion process is a little more complicated than this, but this is the MAJOR STUFF!

Timing explanation is next!

With ADVANCE IN THE TIMING, as car people know it, we are telling the spark when to occurWE ARE NOT MAKING IT OCCUR. OCCURENCE NEEDS TO HAPPEN AT THE SAME POINT (or close to it) every time the PISTON IS HEADING DOWN!

Using “STUPID TERMS”....... Lets say your engine is sitting still, at “0” RPM, at “2 DEGRESS ATDC” I WILL CALL THIS, “0 MPH, Miles Per Hour”, IN STUPID TERMS (Locked and loaded with a compressed fuel mix)If you shoot a spark, the mix will explode and the piston will travel down....... RIGHT? Electricity travels about 200 MPH (basically) THIS WORKS!

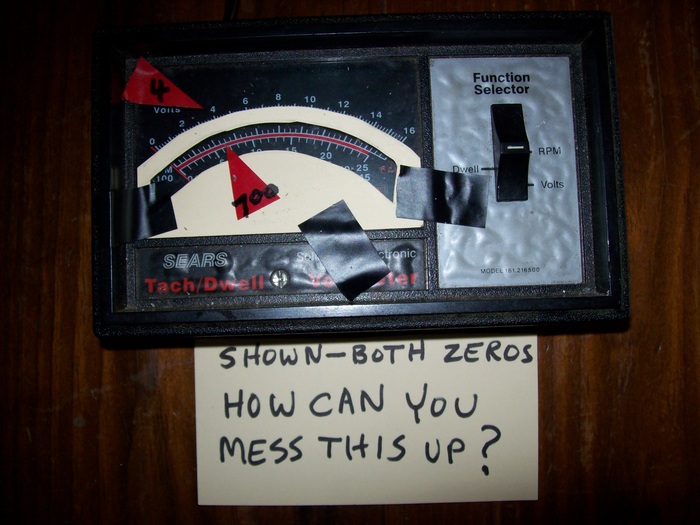

What about now, Your engine is doing 700 RPM, (STUPID TERMS) 700 MPH....... The spark must get to “2 DEGREES ATDC at the same time it did at “0 MPH”HOW, YOU SAY......... TELL IT TO SHOOT SOONER, WE CANNOT SPEED UP ELECTRICITY, SO WE JUST “LEAD IT SOONER”, or “SHOOT IT SOONER”, Or in car terms “ADVANCE IT”

As it gets faster and faster, that’s where the internal distributor CENTRIFAGAL ADVANCE slowly adds advance, as engine speed increases (sorta a self adjusting advance!)

Then we have vacuum advance, sorta a New thing back in maybe the 40’s, it not only helps with fuel economy, it kinda helps the Centrifugal Advance, it too sorta self adjusts....... When everything is wonderful and you are traveling down the road, EZ and “NO LOAD”, Vacuum is high (let’s say 20 Hg) You are Mega Advanced, and all is great. Then you start pulling a steep hill, RPMs are the same (Centrifugal Advance is the same, Remember, it works off of engine speed)......... But Vacuum is dropping, the Vacuum Advance starts Dropping off, (Towards TDC, or back into the Power End of your Explosions, You are still in BTDC, Just Not as far back!

DOES THIS ALL SORTA MAKE SENSE NOW?

THE MEDIC......... With sore fingers!

SPONSORED LINKS

Was this helpful?

Yes

No

Sunday, January 16th, 2011 AT 11:15 PM