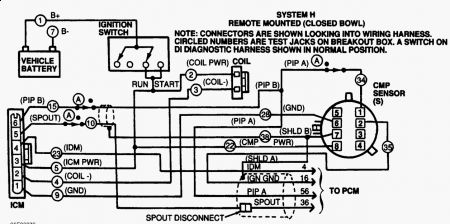

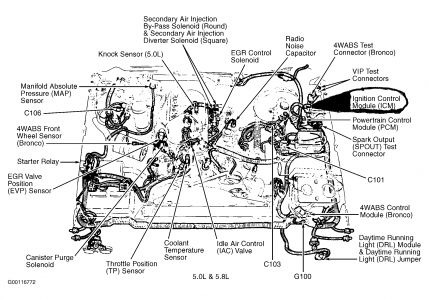

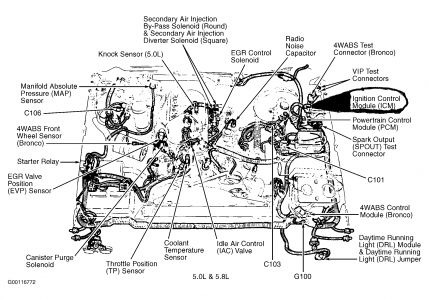

Ignition Control Module (ICM)On left rear side of inner fender panel. See Fig. 1 .

1) Continuous Memory Code 211

Code 211 indicates 2 successive erratic Profile Ignition Pick-Up (PIP) pulses occurred, resulting in a possible engine miss or stall. Check for the following possible causes of fault:

Loose wires or connectors.

Secondary ignition short to ground.

On-board transmitter equipment (2-way radio).

Repair if necessary and repeat QUICK TEST. If problem is not found, go to next step. If vehicle does not start, go to CIRCUIT TEST AA.

2) Continuous Memory Code 212: Check IDM Circuit Continuity -Continuous Memory Code 212 indicates loss of IDM input to PCM. Possible causes for this fault are:

Open or shorted circuit in wiring harness.

Faulty ICM.

Faulty PCM.

If vehicle does not start, go to CIRCUIT TEST AA. If vehicle starts, go to next step.

3) Check IDM Circuit Continuity

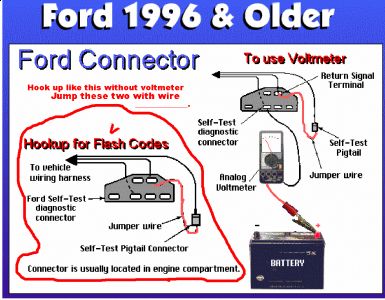

Turn ignition off. Disconnect 60-pin PCM connector. Inspect terminals and repair if damaged. Install EEC-IV Breakout Box (T83L-50-EEC-IV), leaving PCM disconnected. Disconnect ICM. Measure resistance between test pin No. 4 at breakout box and IDM terminal at ICM wiring harness connector. If resistance is 5 ohms or less, go to step 5). If resistance is more than 5 ohms, repair open circuit, and repeat QUICK TEST.

NOTE:A break in step numbering sequence occurs at this point. Procedure skips from step 3) to step 5). No test procedures have been omitted.

5) Check IDM Circuit For Short To Power (Except VREF)

Turn ignition off. Leave ICM and PCM disconnected. Measure voltage between breakout box test pin No. 4 and negative battery terminal. Turn ignition on. Measure voltage between test pin No. 4 and test pins No. 40 and 60 at breakout box. If voltage is more than 10.5 volts, repair short circuit. Clear codes, and repeat QUICK TEST. If voltage is 10.5 volts or less, go to next step.

6) Check IDM Circuit For Short To PIP & VREF

Turn ignition off. Leave PCM and ICM disconnected. Disconnect ignition coil wiring harness connector (non-CCD). Remove scan tester (if applicable). For short to PIP, measure resistance between test pins No. 4 and 56 at breakout box. For short to VREF, measure resistance between test pins No. 4 and 26 at breakout box. If any resistance is 10,000 ohms or less, repair short circuit and repeat QUICK TEST. If each resistance is more than 10,000 ohms, go to next step.

7) Check IDM Circuit For Short To Ground

Turn ignition off. Remove scan tester (if applicable). Leave ignition coil, ICM and PCM disconnected. Measure resistance between test pin No. 4 and test pins No. 20, 40, 46 and 60 at breakout box. If each resistance is more than 10,000 ohms, reconnect scan tester and go to next step. If any resistance is 10,000 ohms or less, repair short to ground in IDM circuit. Clear codes, and repeat QUICK TEST.

8) Check ICM

Turn ignition off. Connect PCM to breakout box. Reconnect ICM and ignition coil to wiring harness connectors. Connect DVOM between test pins No. 4 and 16 at breakout box. Start engine. Observe DVOM for voltage surge while lightly tapping on ICM and Camshaft Position (CMP) sensor to simulate road shock. Wiggle all ICM and CMP sensor wiring and harness connectors. If fault (voltage surge) is indicated, disconnect and inspect wiring harness connectors and terminals for damage. If fault is not indicated, go to next step.

9) Check PCM & Harness Connectors

Ensure engine is still running and DVOM is still connected between test pins No. 4 and 16 at breakout box. While observing DVOM, wiggle and bend wiring harness, a small section at a time, from ICM and CMP sensor (if equipped) to cowl. Also check harness from cowl to PCM. If fault is indicated, isolate fault and repair as necessary. Remove breakout box, reconnect all components, and repeat QUICK TEST. If no fault is found, go to next step.

10) Check PCM & Harness Connectors

Turn ignition off. Disconnect PCM 60-pin connector. Inspect connector for damaged pins, corrosion and loose wires. If connector is damaged, repair as necessary. Clear codes, and repeat QUICK TEST. If connector is okay, go to next step.

11) Check PCM For Short To Power

Turn ignition off. Connect PCM to breakout box. Disconnect CMP wiring harness connector. Measure voltage between test pin No. 4 at breakout box and chassis ground. Turn ignition on. Measure voltage between test pin No. 4 and test pins No. 40 and 60 at breakout box. If either voltage reading is more than 10.5 volts, replace PCM and repeat QUICK TEST. If both voltage readings are 10.5 volts or less, go to next step.

12) Check PCM For Short To Ground

Turn ignition off. Leave PCM connected to breakout box. Measure resistance between test pin No. 4 and test pins No. 40, 46 and 60 at breakout box. If resistance is more than 10,000 ohms, check ignition system. See SYSTEM/COMPONENT TESTS - EEC-IV (5.0L) article. If resistance is 10,000 ohms or less, replace PCM and repeat QUICK TEST.

****CODE 452.....Insufficient Input From Vehicle Speed Sensor To Powertrain Control Module***

Wednesday, October 28th, 2020 AT 11:44 AM

(Merged)