TERCEL

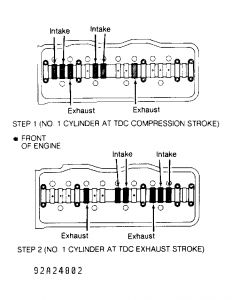

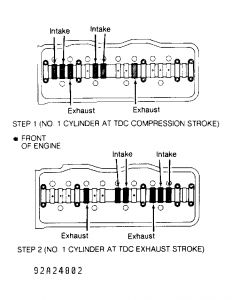

1.Check and adjust valve clearance with engine at normal operating temperature. Remove valve cover and gasket. Rotate crankshaft pulley so crankshaft pulley groove aligns with "0" mark on timing belt cover and cylinder No. 1 (front cylinder at timing belt end) is at TDC on compression stroke.

2.Ensure rocker arms on cylinder No. 1 are loose and rocker arms on cylinder No. 4 are tight. If rocker arms are not as described, rotate crankshaft 360 degrees and realign pulley groove with "0" mark on timing belt cover.

3.To check valve clearance, measure clearance between camshaft lobe and rocker arm on proper intake and exhaust valves using proper thickness feeler gauge. Perform STEP 1. See Fig . Valve clearance should be within specification. (008 in )

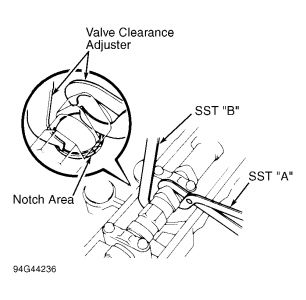

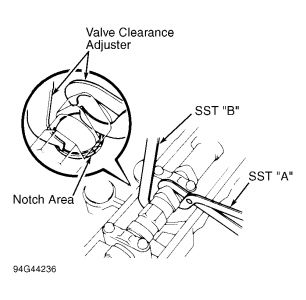

4.Adjust valve clearance if necessary by loosening adjusting screw lock nut and rotating adjusting screw. Tighten lock nut. Recheck valve clearance.

5.Rotate crankshaft 360 degrees, and realign pulley groove with "0" mark on timing belt cover. This will place cylinder No. 1 at TDC of exhaust stroke. Check valve clearance on remaining valves. Perform STEP 2. See Fig. 3 . Adjust valve clearance if necessary. Shim thickness can also be determined by using the following formula: N = T + A.

N = Thickness of adjuster shim required.

T = Thickness of adjuster shim removed.

A = Measured clearance minus valve clearance specification.

6.Apply sealant at camshaft bearing caps-to-cylinder head surfaces where valve cover gasket seals. Install valve cover using NEW gasket.

SPONSORED LINKS

Thursday, October 16th, 2008 AT 5:38 AM