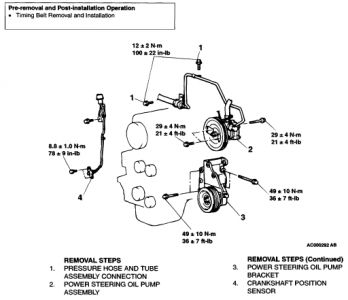

CPS

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINT

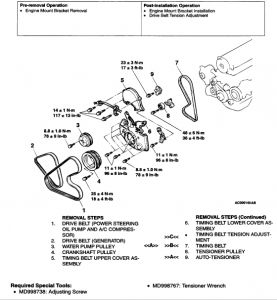

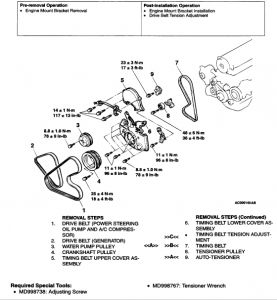

<> TIMING BELT REMOVAL

CAUTION: The crankshaft should always be turned in the forward direction only.

Turn the crankshaft in the forward direction (to the right) to align the camshaft sprocket timing marks.

Loosen the tension pulley fixing bolt. CAUTION: If the timing belt is to be re-used, use chalk to mark (on its flat side) an arrow indicating the clockwise direction.

Move the tension pulley to the water pump side, and then remove the timing belt.

INSTALLATION SERVICE POINTS

>>A<< AUTO-TENSIONER INSTALLATION

Apply 98 - 196 N (22 - 44 pound) force to the pushrod of the auto-tensioner by pressing it against a metal object (such as the engine block) and measure the movement of the pushrod. Standard value: Within 1 mm (0.04 inch) A: Length when it is free (not pressed) B: Length when it is pressed A - B: Movement

If it is outside the standard value, replace the auto-tensioner. CAUTION: Never compress the pushrod too fast, or it may be damaged.

Use a press or vise to gently compress the auto-tensioner pushrod until pin hole A of the pushrod and pin hole B of the tensioner cylinder are aligned.

When the holes are aligned, insert the set pin. NOTE: When replacing the auto-tensioner with a new part, the pin will be in the auto-tensioner.

Install the auto-tensioner to the engine. >>B<< TIMING BELT INSTALLATION

Align the timing marks on the camshaft sprocket, crankshaft sprocket and oil pump sprocket.

After aligning the timing mark on the oil pump sprocket, remove the cylinder block plug and insert a Phillips(r) head 8 mm (0.3 inch) screwdriver. Check to be sure that the screwdriver goes in 60 mm (2.4 inches) or more. If the screwdriver will only go in 20 - 25 mm (0.8 - 1.0 inch) before striking the counterbalance shaft, turn the sprocket once, realign the timing marks and check that the screwdriver goes in 60 mm (2.4 inches) or more. The screwdriver should not be taken out until the timing belt is installed. CAUTION: the timing belt is re-used, install so that the arrow marked on it at time of removal is pointing in the clockwise direction.

Install the belt to the crankshaft sprocket, oil pump sprocket and camshaft sprocket in that order, so that there is no slackness in the belt tension.

Set the tension pulley so that the pin holes are at the bottom, press the tension pulley lightly against the timing belt, and then provisionally tighten the fixing bolt.

Adjust the timing belt tension. >>C<< TIMING BELT TENSION ADJUSTMENT CAUTION: Do not use a spanner or the similar tool to turn special tool MD998738.. Otherwise, the auto-tensioner set pin may be broken. Turn special tool MD998738 by hand only.

Remove the rubber plug from the rear of the timing belt cover assembly. Then screw in special tool MD998738 by hand until the tensioner arm is touching the auto-tensioner pushrod.

After turning the crankshaft 1/4 of a revolution in the counterclockwise direction, turn it in the clockwise direction until the timing marks are aligned. CAUTION: When tightening the fixing bolt, make sure that the tension pulley does not turn with the bolt.

Loosen the tension pulley fixing bolt, and then use special tool MD998767 and a torque wrench to tighten the fixing bolt to the specified torque while applying tension to the timing belt. Timing belt tension torque: 3.5 Nm (31 inch lbs.) Tightening torque: 48 ±6 Nm (36 ±4 ft. lbs.)

Remove the set pin that has been inserted into the auto tensioner, and then remove special tool MD998767.

Turn the crankshaft two revolutions clockwise so that the timing marks are aligned. After leaving it for 15 minutes, measure the amount of protrusion of the auto-tensioner. Standard value (A): 3.8 - 4.5 mm (0.15 - 0.18 inch)

If the amount of protrusion is outside the standard value, repeat steps 1 through (5).

Check again to be sure that the timing marks of each sprocket are aligned.

https://www.2carpros.com/kpages/auto_repair_manuals_alldata.htm

Wednesday, July 1st, 2020 AT 1:40 PM

(Merged)