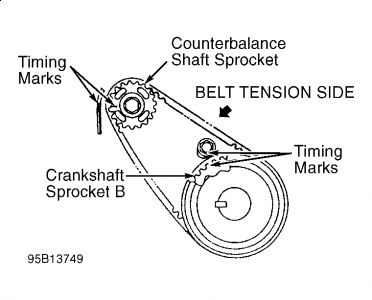

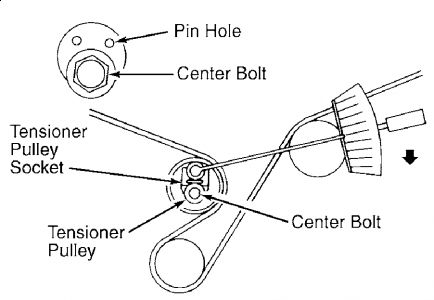

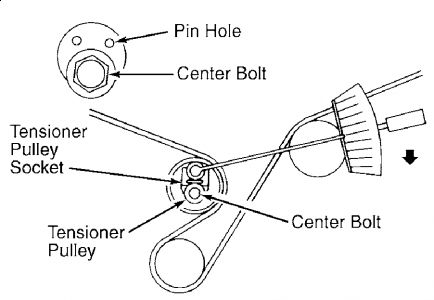

Installation (Eclipse & Galant) 1. Place auto-tensioner in soft-jawed vise to SLOWLY compress the push rod. If there is a plug at the base of the auto-tensioner body, place flat washer around plug so it will not contact vise jaw. 2. Slowly compress auto-tensioner push rod until holes in push rod and auto-tensioner housing are aligned. Insert a locking pin into the alignment holes. Install auto-tensioner on engine. 3. Ensure all timing marks are still aligned. See Fig. 2. Install timing belt on crankshaft sprocket, idler pulley, left bank camshaft sprocket, water pump pulley, right bank camshaft sprocket, and tensioner pulley. Take all slack out of timing belt. 4. Loosen the tensioner pulley center bolt. Using Tensioner Pulley Socket Wrench (MD998767), rotate tensioner pulley against timing belt. Temporarily tighten tensioner pulley center bolt. Using Crankshaft Pulley Spacer (MD998769), turn crankshaft 1/4 turn counterclockwise. Turn crankshaft 1/4 turn clockwise. Ensure all timing belt marks are still aligned. 5. For 1999-00 models, loosen tensioner pulley center bolt. Position tensioner pin holes at BOTTOM of tensioner. Install Tensioner Pulley Socket Wrench (MD998767) on tensioner pulley. See Fig. 6. Use a torque wrench to apply 39 INCH lbs. (4.4 N.m) of torque (counterclockwise direction) to tensioner pulley. Tighten tensioner center bolt to specification while holding tensioner stationary. See TORQUE SPECIFICATIONS. 6. For 2001 and later models, loosen tensioner pulley center bolt. Position tensioner pin holes at TOP of tensioner. Install Tensioner Pulley Socket Wrench (MD998767) on tensioner pulley. See Fig. 7. Use a torque wrench to apply 39 INCH lbs. (4.4 N.m) of torque (clockwise direction) to tensioner pulley. Tighten tensioner center bolt to specification while holding tensioner stationary. See TORQUE SPECIFICATIONS. 7. On all models, remove locking pin from auto-tensioner. Turn crankshaft 2 revolutions clockwise and align all timing marks. DO NOT rotate counterclockwise. 8. Wait for at least 5 minutes, then check auto-tensioner push rod protrusion. To check push rod protrusion, measure clearance between body of auto-tensioner and bottom of tensioner pulley bracket arm. Clearance should be 0.15-0.20" (3.8-5.0 mm). If protrusion is not correct, repeat timing belt tensioning procedure. 9. Install engine support bracket on engine block. Tighten top bolt first, then working in a counterclockwise direction, tighten the remaining bolts. See Fig. 8. Install timing belt covers. Install crankshaft pulley. Apply engine oil to crankshaft pulley bolt, then tighten bolt to specification. See TORQUE SPECIFICATIONS. 10. To install remaining components, reverse removal procedure. Adjust drive belts to proper tension. CAUTION: Never compress the auto-tensioner too fast, or the push rod will be damaged. WARNING: Right bank camshaft can turn easily due to applied spring force, so keep fingers out of the way.

Wednesday, July 1st, 2020 AT 1:39 PM

(Merged)