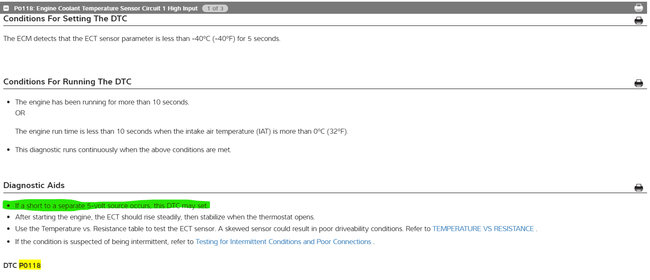

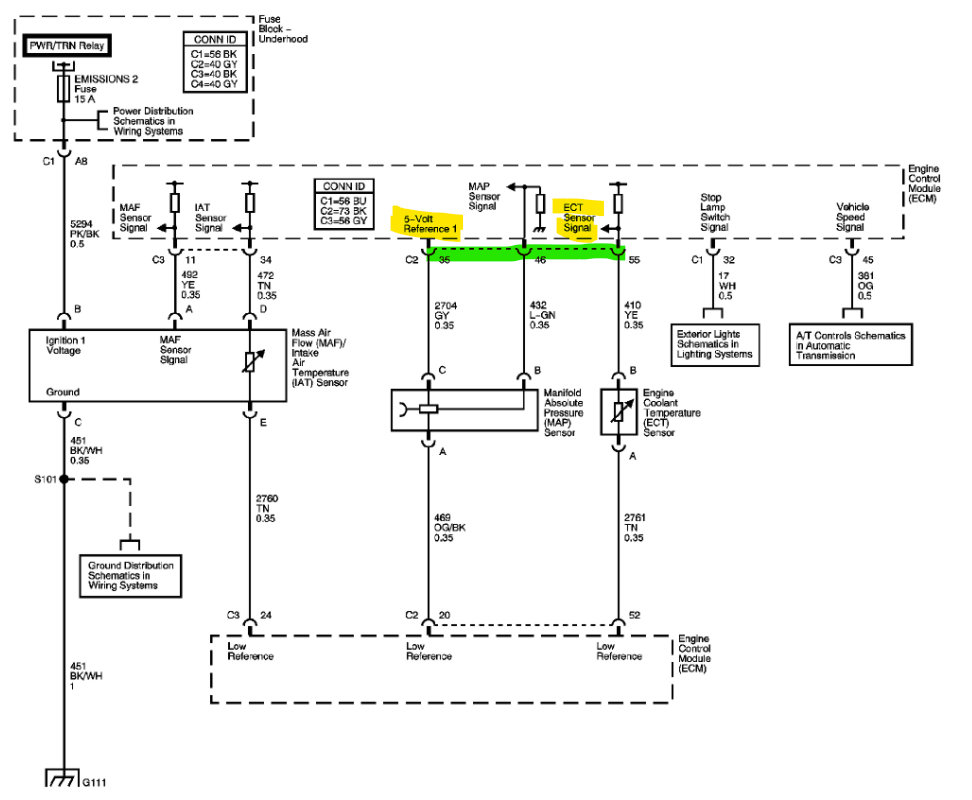

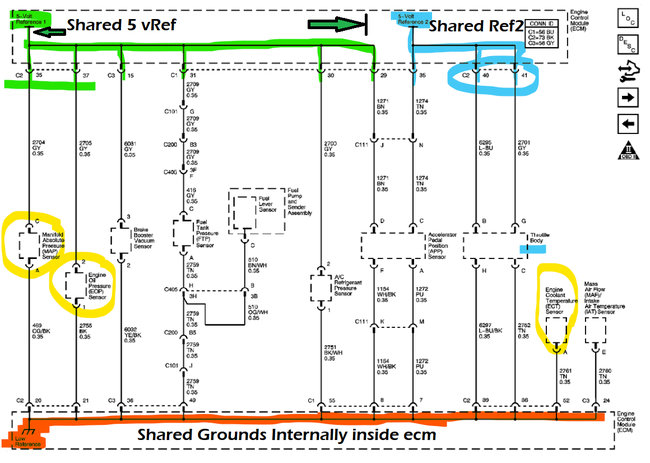

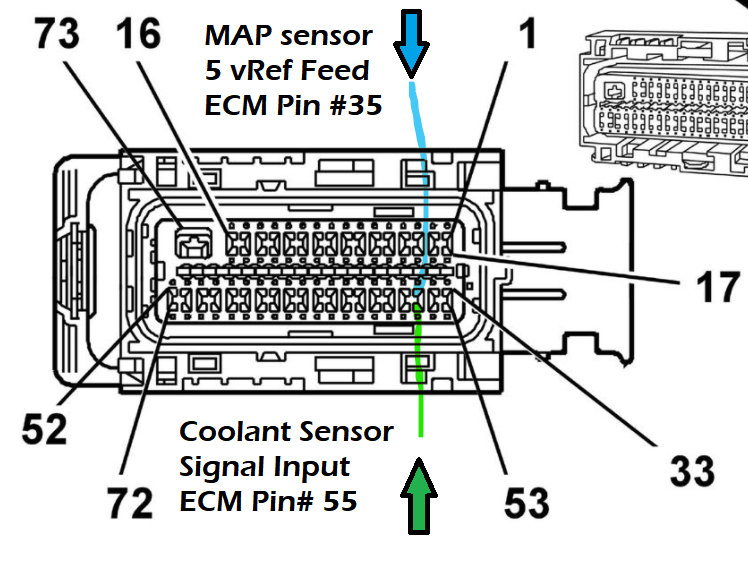

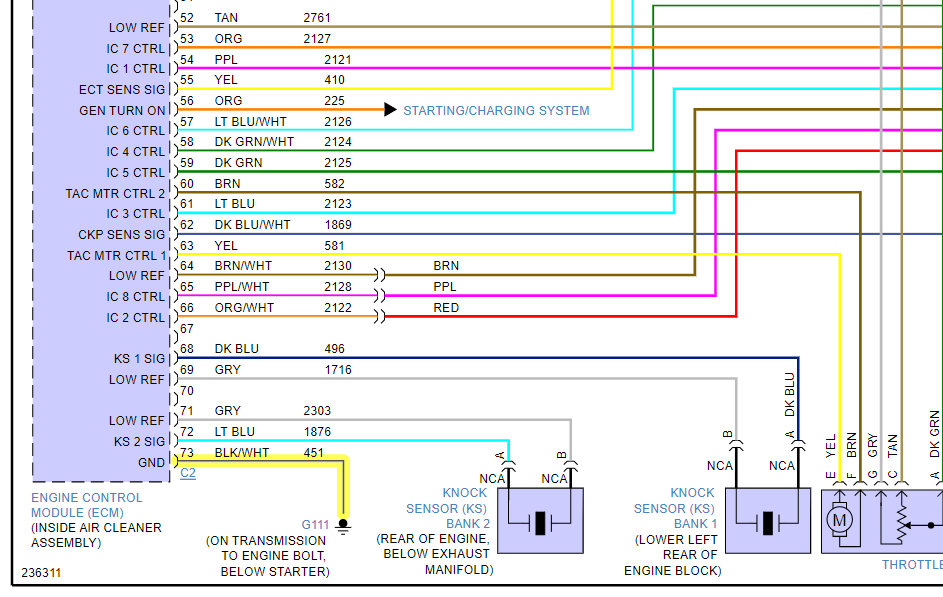

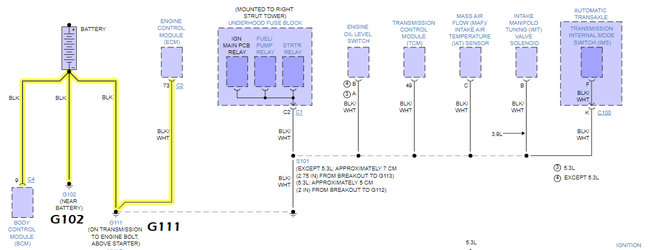

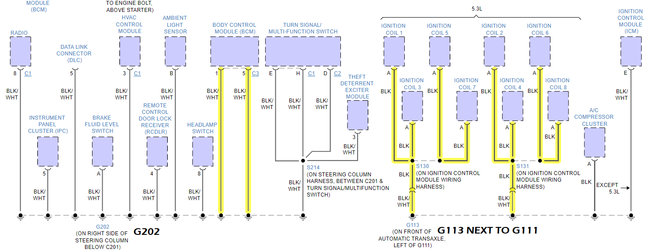

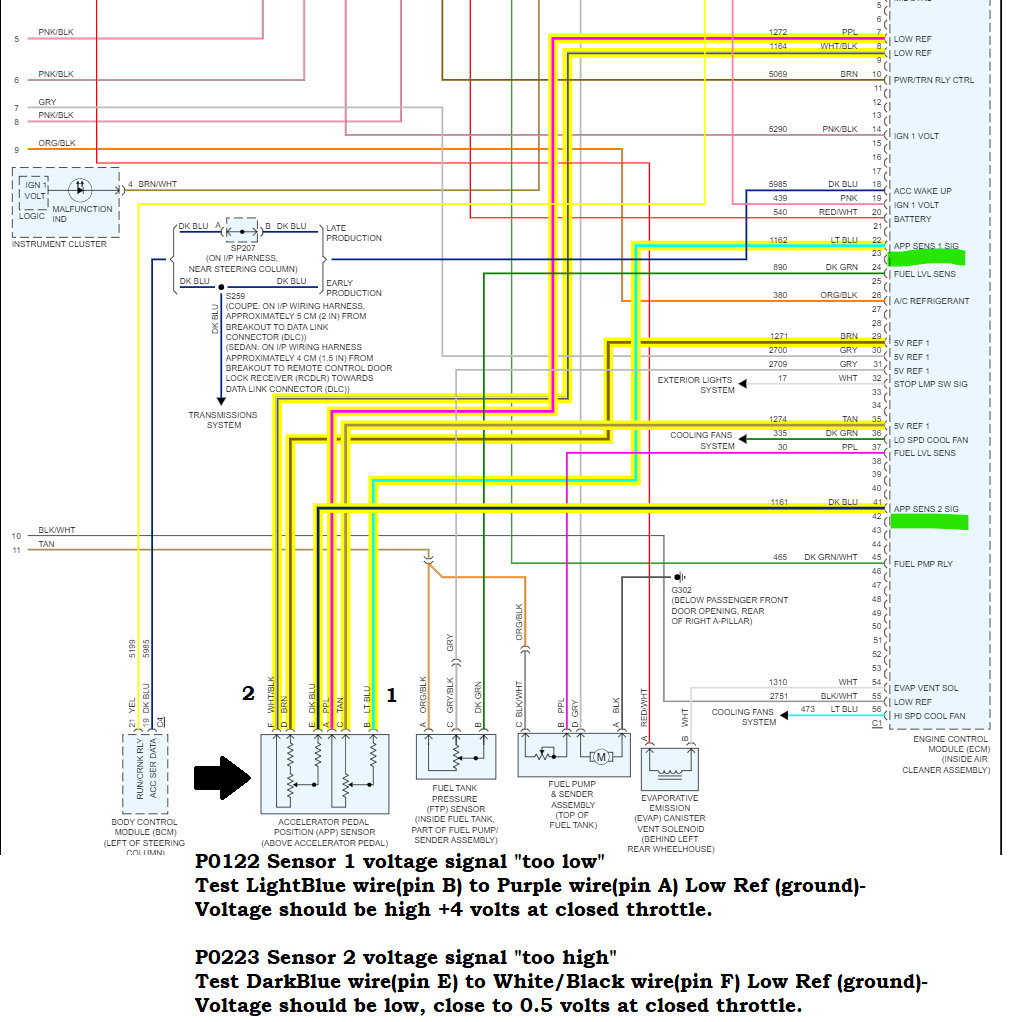

So, then I looked at the Chevrolet OEM diagrams and found that the Coolant Sensor signal input wire to the ECM and the MAP sensors 5v Ref feed wire pins at the ECM are right next to each other. I will put the diagrams below. I think the Map sensor 5vRef is shorting to the Coolant sensors input Signal wire at the ECM connector, there might be a bent pin there or some corrosion, but it makes sense that the Map sensors signal would be low, and the Coolant sensors signal would be High input just like the first 2 codes you're getting.

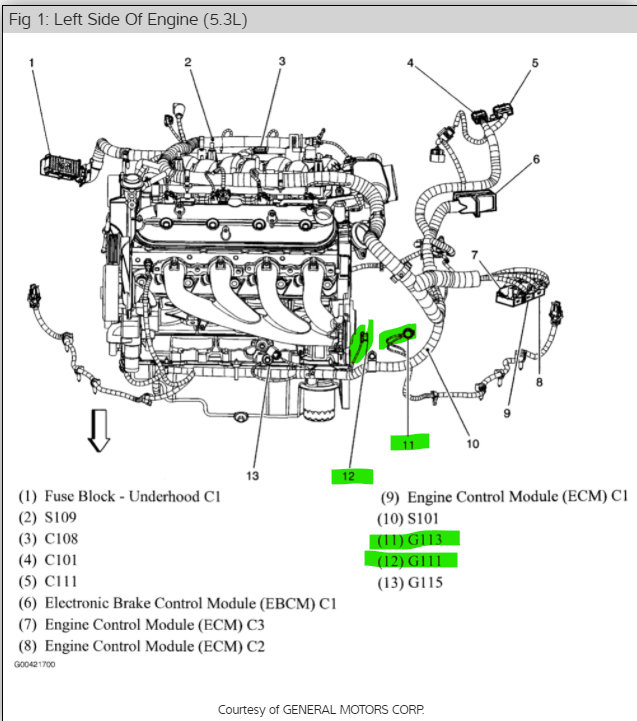

I'm not sure if you unplugged the ECM C2 connector or not, but I think this is what's happening, after seeing where the pin locations were and that the coolant sensor code can set due to a "different Reference voltage being shorted to it", this would explain why you're not reading anything at ECM pins 35 and 37, I just wondering why you're not getting any other codes, unless it's because the Map sensors Ref V is first in line and being pulled down first, therefore messing with the ECM.

Watch I'll probably be wrong after all that, but do a real good inspection of that C2 ECM connector and the pins in the ECM side of the connection.

Try the suggestions about the Oil Pressure sensor and MAP sensor also in the previous post. Just to be sure of what's happening here. I want to be sure we know what we're dealing with. A clue too was the new codes you got, something got messed with when the wiring harness was moved around for testing.

SPONSORED LINKS

Was this helpful?

Yes

No

Monday, February 14th, 2022 AT 6:55 PM