No emissions that I'm aware of. I'd be exempt even if I did because of the low mileage. So what you're saying is I did the right thing with the valves and the floats and that they don't need to be bent?

I'm not planning anytime at the track. I just like to enjoy driving it if I ever can again. I don't want anymore under hood explosions which would lead to having to go through this again. I know a lot of times people say you can fix this with timing but I' don't think I have a timing issue I have a too hot issue.

Background. We've had some incredibly hot summers the last few years hanging out in the upper 90's for weeks on end and that I think was largely responsible for my 50 year old brass and copper radiator to perspire. I'd no sooner have one leak fixed and another would start. We tried to save it but it just wasn't possible. I had been reading about the new aluminum radiators and how they were so much better at dissipating heat with fewer rows and not having to hear the roar of my mechanical fan was just a huge plus to replace it with an electric fan. But what no one would tell me or even admit to was that very few 454BB were able to stay cool with a 16" electric fan and a shroud that prevented any extra air flow from coming through. And no matter how many people I asked that had done their own cars over or had them professionally done no one would tell me how well their cooling system worked or what they used to cool it. Which means they could just be someone else's cars that they have no clue about or they didn't really do them themselves. Most of the posts I've read are about this same problem being able to cool them with an electric setup. I've learned lots about it and I'm convinced it's largely in the radiator being blocked by the shroud and a weak fan on top of that with pushers having no place to blow. I think initially I may just put the mechanical back on with the new radiator to see how that goes because believe it or not when I had the radiator replaced they didn't clean out the stop leak from the old leaky radiator before they dropped in a brand new radiator. I was pissed. That was the end of my 18 year mechanic. I never had such terrible service from him in my life. He used to be incredible and he's restored old Ford pickups, scooters, motorcycles, he has his own setup at home so he really enjoys it but this was a fuck up.

One day I was running about 225 just 3 blocks from home. I was worried. I had never seen it that high before. Well I made it home of course once it was turned off there was still a lot of heat to remove on a 95+ degree day and the fan only ran for like 30 seconds and shut off. I was expecting a little more action from that electric fan like running and shutting off over and over on whatever cycle but there was no more. My mechanic hadn't said anything at all about not cooling well or anything to even let me know that I'd better watch my temperature. Even when I had the first A/C system put in they weren't happy with the cooling using the old mechanical fan. They ended up pulling a trick by using a lower degree thermostat. Some people say that it doesn't do what you think an others seem to think it's a solution. It seemed to work for a couple years until the radiator just gave up.

After the new radiator was in it was so nice to hear again. I could hear the roar of my mufflers a much nicer sound than the fan blowing. One day after I had been vandalized it was like the middle of winter and very cold and foggy and I was out with a friend trying to get some estimates on fixing the interior when I started to notice there didn't seem to be any heat when I was running the defroster. What I came to find out was that the Vintage Air system I bought shut off the heat when you turned on the defrost. I never heard of such a thing. I contacted Vintage Air and I was told that I needed to buy a $50 part. At the time I just didn't have the money and so I contacted the CEO and told them my problem and he offered to replace the entire system for their newer system that was run by servos. I wasn't exactly sure why I needed servos but this guy was being incredible nice and offering to pay for the install. My gut reaction was that it took almost 12 years to flush the first system out because you don't use the car that much to begin with and there was some kind of a refrigerant leak that we just couldn't find. Finally with the service writer and me both on our backs under the car we finally saw the dye coming from the Schrader valve. Every year I was replacing refrigerant. What a difference but it took 12 years to find it. The other problem was the A/C was on or off which I had thought was a control issue. I had them put a switch on the compressor that I could turn on and off. I was thinking there was some type of granularity problem that I couldn't move the slider in a small enough range that it was shutting off the compressor and instead of changing the temperature. Turns out there was NO HEAT at all if you had the A/C on you couldn't adjust the temperature at all. You were frozen or burning up your only 2 choices. Again this was all weighing on my mind about replacing a system that I just figured out. I told the CEO my concern and I asked if it would be OK to think about it for a few days. Certainly he said you just let me know. I was having a hell of a time convincing myself. I finally pulled the trigger and the bullet was shot right into my car. It drove home OK but when I went to shut it off it started dieseling which it had only ever did once on a very hot day but it was far from hot. There was a cloud of smoke surrounding the car while it was running that made your eyes burn and smelled just horrible of gas. But nothing they did should have caused this. I called the "installers" and left a message that night and said it was coming back that something was wrong. They called me later that next day saying the only thing they could find was that the fan regulator had lost it's settings and should be replaced and there was a wire that had come loose from the fan controller, I needed a tune-up (which I had just done the year before) and my timing was all screwed up, I had a weak battery, I needed a new thermostat (which had just been replaced with the new radiator). Really? They weren't admitting anything. I had a list of things like not keeping the car warm inside and running incredible rich, and there was a light that had stopped working and on and on with what seemed like little things but even the hose that came out of the car to get rid of the water was left laying on my headers and literally burnt off. The installer told me that he took some wire under the dash that had multiple drops and he rewired it (who asked him to?) They lied right to my face about some wires I asked him to run while the heater box was out magically they appeared with hanging over the master cylinder like so obvious that I couldn't have missed them but the oil pressure sender I asked him to put in he decided didn't work so he took it back out and left nothing and didn't even mention that he took it out. But he takes it upon himself to re-wire my car? I told him a million times if he had any questions to call me because I knew how the thing was put together. They had answers for everything I needed a new fan controller and I needed all new plugs, I needed to buy a new alternator and the list went on and on and I new that alternator was all but brand new. It wasn't the 37amp one that came with the car.

I realized they weren't capable of fixing this because they were installers I could have installed it following the directions (as long as Holley didn't write them). By the time I was done arguing and getting no where a storm had rolled in. It was a terrible thunderstorm and the car was under full load with everything running including the new A/C to defrost the windows and every time I would hit a red light the car would go dead. The weather had changed drastically from upper 90's to upper 50's overnight. Well the car wasn't dying when I stopped after the temperature change but it was fussy at best.

Imagine it worked fine when it went in and when it came back I could barely keep it running. None of it made sense until I had disconnected the A/C pusher fan which was just blowing air against the radiator but there was no place for the air to go because of the way the shroud was made to be tight up against the back of the radiator which got me thinking about how restricted this air flow was in relation to my old mechanical fan and shroud. Even if the electric fan was able to blow 3000 cfm it still was only accessing less than 40% of the radiators surface. I either had to redesign the shroud or put the old mechanical fan back in.

A funny thing happened while I was looking over various things I happened to be out making a test run and the car wanted to stall at the light. I jumped out quickly and disconnected that pusher fan and the car sprang back to life. Well that was interesting. When I got back home I was following the wiring for the pusher fan and found that the relay was shorted from the control side to the action side well that would explain a lot but not why they didn't find this problem when they hooked up the new fan. I also found out that the fans were reversed. The main fan was running with the A/C and the pusher was running constantly cooling the car and they denied that too. OMG, This is exactly why I didn't want to replace the system. The worst possible outcome is now in my lap because no one will touch it because they don't want to be blamed.

I have chronic pain so it takes me forever and a day to be able to fix or even find out what needs fixed. You wouldn't happen to be close by south central PA would you?

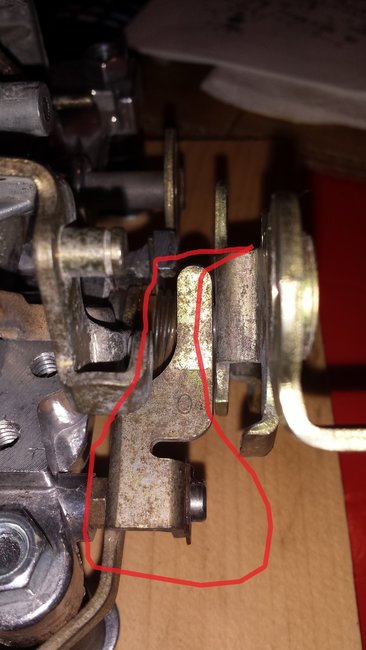

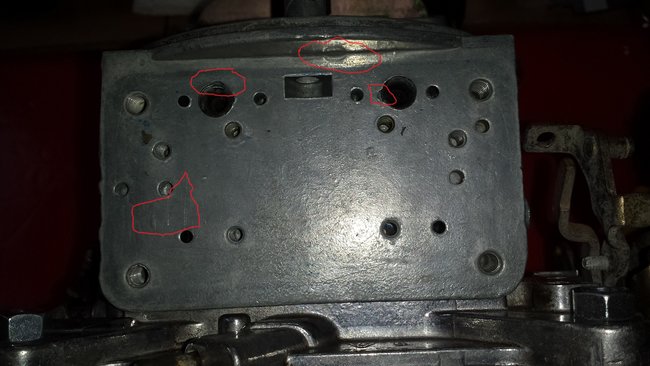

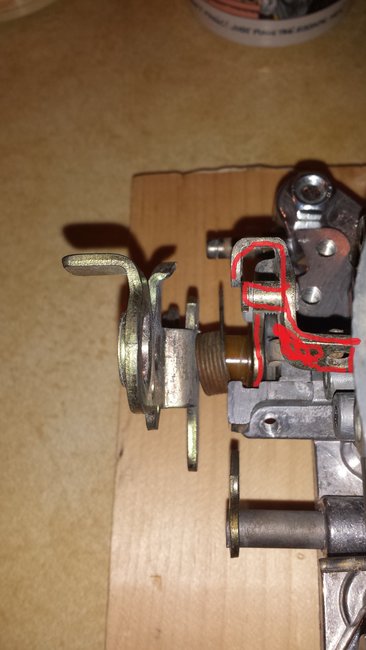

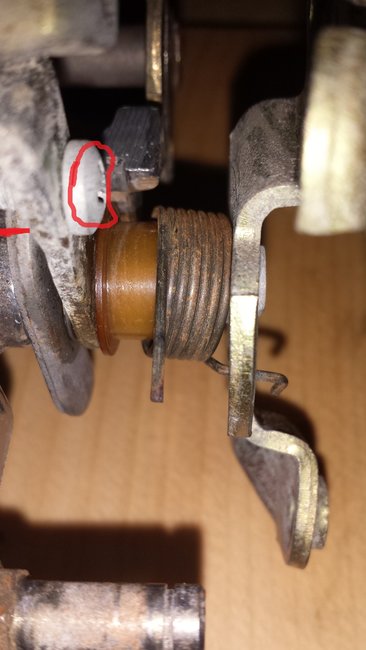

Anyway the first major problem is to get the car running normal. Then it has to be able to cool itself again. I have a couple ideas in mind but first off this carb has to get done and then I have to go the through the plugs and probably replace them or at least clean them because this event is what caused all this carbon fouling and the last thing I want to do is put the carb in only to have it explode yet again under the hood and be back to square one. I know the snorkel air cleaners used to put what looked like a sieve in the snorkel to stop explosions although how that worked I don't know. There is also the A/C solenoid method to shut the choke plate or maybe I can fool the electric choke into closing the plate?

Tuesday, May 11th, 2021 AT 7:47 PM