Diagnosing a blown head gasket in an automotive engine requires a systematic approach to ensure accurate results. This guide will walk you through the necessary steps to identify a blown head gasket using various diagnostic methods.

What Goes Wrong?

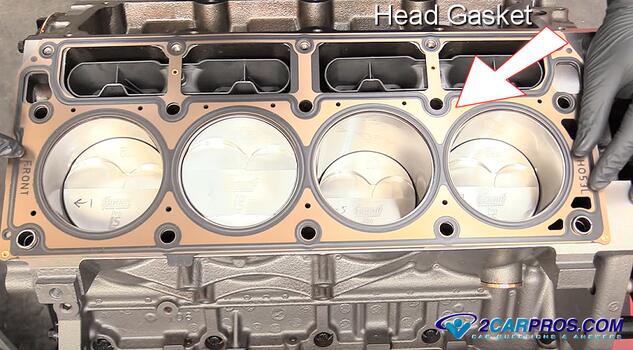

Head gaskets are made up of thin metal plates bonded together with a hard gasket composite. Because of the constant expanding and contracting during the engine's heat cycle, and the acidity of the coolant a head gasket can become weak and fail. These gaskets must withstand the extreme force of the combustion process while holding cooling system pressure, which enables the transfer of antifreeze from the engine block to the cylinder head. The most common problem you will notice when the head gasket fails is the engine overheating.

Pro Tip: If the engine coolant is not flushed and is neglected it will turn acidic, which eats away at the gaskets throughout the engine and especially the metal parts of the head gasket.

When the gasket fails, it can do so in one of five different ways:

- Allows coolant into the engine oil

- Allows coolant to leak outside of the engine

- Forces combustion gasses into the cooling system (radiator)

- Allows compression to transfer between two cylinders

- Allows engine oil to leak outside of the engine

Blown Head Gasket Testing

Begin with the vehicle parked on level ground, engine cold, with the parking brake set. Use appropriate personal protective equipment (PPE) to avoid injury (protective gloves and eyewear). Always follow safety precautions when working on an engine.

1. Remove Oil Fill Cap and Dipstick

With the engine cold, remove the oil fill cap to inspect for brown milky goo that has collected on the bottom of the cap, which is an indication that coolant is leaking into the oil. Chances are the head gasket has failed, but if the engine has been severely overheated it could have a cracked cylinder head, or engine block.

It should be noted that V8 and V6 engines may have a leaking intake manifold gasket which can cause the same affect. Also, remove the oil level dipstick which can show the same "chocolate milk" as some call it indicating a blown head gasket. You can also drain a small amount of engine oil for inspection as well.

Note: A small amount of moisture may be present inside an engine that doesn't get much usage which is normal.

2. Bubbles in the Radiator

With the engine cold remove the radiator cap and start the engine, if the head gasket has failed it will allow combustion gases into the cooling system. Use a flashlight to observe the coolant inside the radiator tank, if there is a continuous stream of bubbles while the engine is running the head gasket is blown and needs replacement. This is what it will look like if the head gasket is leaking combustion gages inside the radiator and cooling system.

3. White Steam or Smoke From Exhaust

When coolant is being burnt inside the combustion chamber due to a blown head gasket the exhaust system will produce "white smoke" or "steam" from the car's tailpipe, and it will have a pungent smell. This smoke should not be confused with engine cold start steam which dissipates after a few minutes of driving.

4. Unexplained Coolant Loss

When a head gasket fails it can cause the engine to consume coolant while driving. This is first noticed as the coolant level continues to drop with no external leaks.

5. Coolant Inside the Combustion Chamber

If coolant is allowed to enter the combustion chamber the cylinder head gasket is blown, to check for this remove the spark plugs and then use a pressure tester to build pressure inside the engine's cooling system. Once all spark plugs have been removed, pressurize the cooling system and crank the engine over (stand back) while observing the spark plug holes. if coolant is present at any one of the holes the head gasket is blown.

6. Chemical Test

1. Reinstall the spark plugs, for this test you will need a head gasket chemical tester which you can get from Amazon or the local parts store. This test will help measure the amount of exhaust gases inside the cooling system. Remove the radiator cap and then drain a small amount of coolant from the as to not contaminate the test fluid, (about 2 inches from the top of the radiator). This can be done by using an exhaust gas analyzer as well by detecting the presence of hydrocarbons (HC) in the coolant, indicating a blown head gasket.

2. Once the coolant has been drained down slightly, insert the test tube into the radiator filler neck, then add test fluid to the full line on the side of the tube.

3. Start the engine, while using the hand pump draw air inside the radiator into the tester, repeat this action about 10 times.

4. If the test fluid turns yellow exhaust gases are present and the head gasket is blown. If the fluid remains blue the system is most likely okay.

Pro Tip: Sometimes this test can fail and cause a false negative because the combustion process is not 100% efficient. Small consistent pockets of fuel enriched air (not exhaust) exist inside the combustion chamber after ignition which is not detected by this test.

7. Cylinder Compression Test

A head gasket can fail between cylinders causing two consistent cylinder misfires and low compression in each misfiring cylinder. To check for this condition remove all of the spark plugs while conducting a compression test to test each cylinder. If two readings are consistently low in neighboring cylinders this is an indication of failure between these cylinders and the head gasket needs to be replaced. This is what the gauge will look like if the compression is low

8. External Leakage

Some engines are designed with oil pressure passing though the engine block and into the cylinder head along with engine coolant (each in separate ports) via the head gasket. When the gasket fails it can cause an engine oil or coolant leak which is detectable by a manual inspection.

Quick Fix?

Not being a believer in pour in solutions, we had to give this product the "Best On Market" award because it does a good job fixing minor head gasket failures. It wont cure all failures, but the Blue Devil head gasket sealer works well and is available on Amazon for about $50.00.

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.