Welcome back:

I'm glad you found the problem. That is good news. Now for the not so good news. You need to remove the fuel tank to access the sensor. I will provide directions for removal and replacement of the tank. Then, I will add the directions for replacement of the sensor. The attached pictures will correlate with the directions. Note, the directions for tank removal indicate tank replacement. However, the same directions apply. You just don't need to replace the tank.

__________________________________

FUEL TANK REPLACEMENT

REMOVAL PROCEDURE

1. Ensure that the fuel level in the tank is less than 1/4 full. If necessary, drain the fuel tank to at least this level. Refer to Fuel Tank Draining Procedure.

CAUTION: Do not allow smoking or the use of open flames in the area where work on the fuel or EVAP system is taking place. Anytime work is being done on the fuel system, disconnect the negative battery cable, except for those tests where battery voltage is required.

2. Relieve the fuel system pressure. Refer to Fuel Pressure Relief Procedure.

CAUTION: Fuel supply lines will remain pressurized for long periods of time after the engine is shutdown. This pressure must be relieved before servicing the fuel system.

3. Disconnect the negative battery cable.

4. Raise and support the vehicle. Refer to Vehicle Lifting.

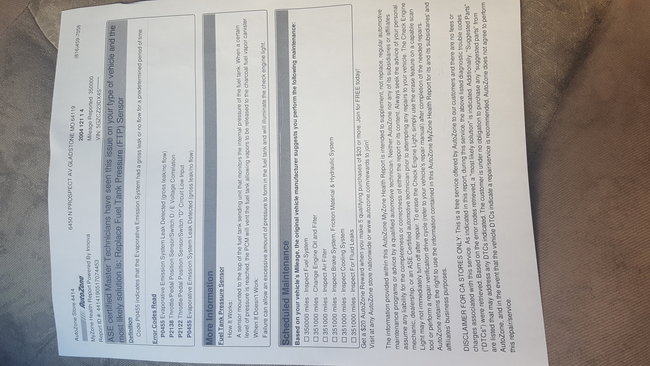

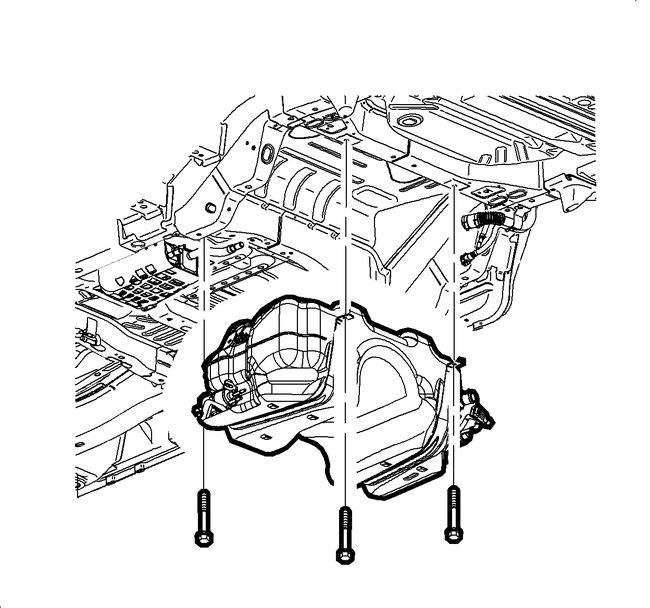

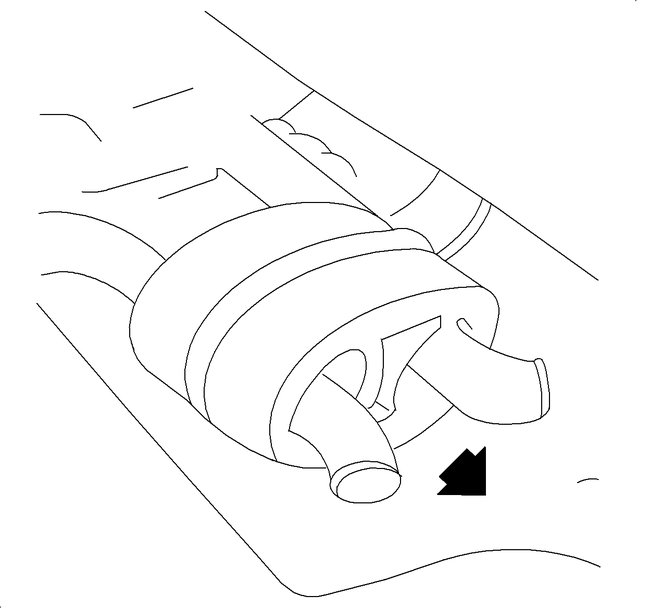

Pic 1

5. Remove the rubber exhaust hangers on order to allow the exhaust system to drop slightly.

6. Remove the propeller shaft, if equipped.

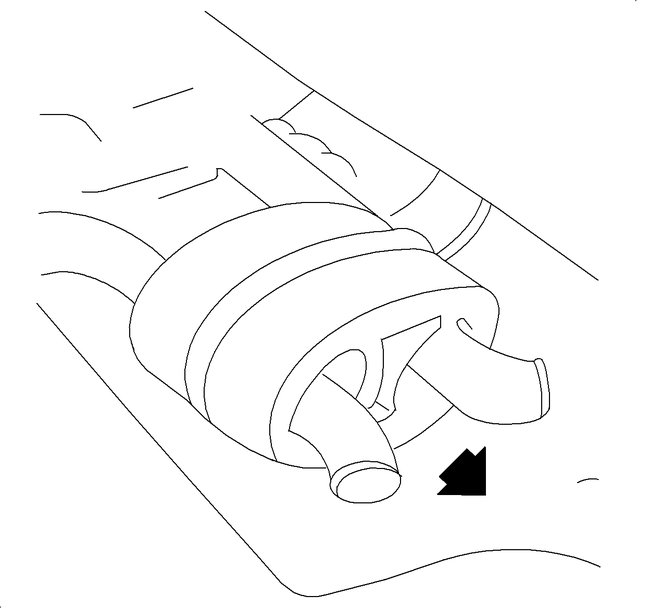

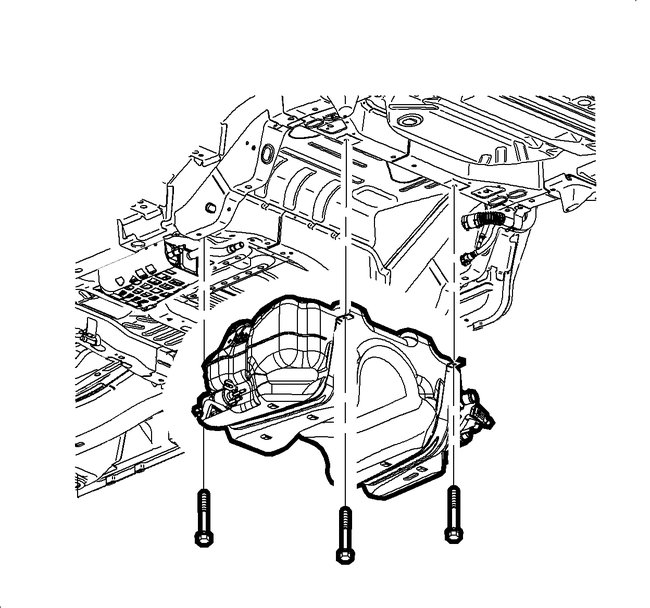

Pic 2

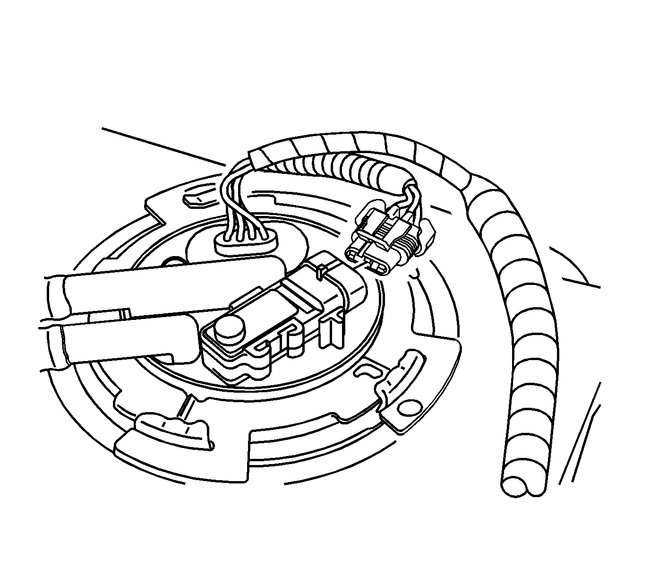

7. Disconnect the EVAP canister vent and fresh air hoses:

NOTE: Clean all fuel pipe connections and surrounding areas before disconnecting the fuel pipes to avoid contamination of the fuel system.

1. Grasping both sides of the quick-connect fitting, twist the female connector 1/4 turn in each direction in order to loosen dirt within the quick-connect fitting.

2. Blow any dirt out of the quick-connect fitting using compressed air.

3. Squeeze the plastic retainer release tabs.

4. Pull the connection apart.

5. Inspect both ends of the quick-connect fitting for dirt and burrs.

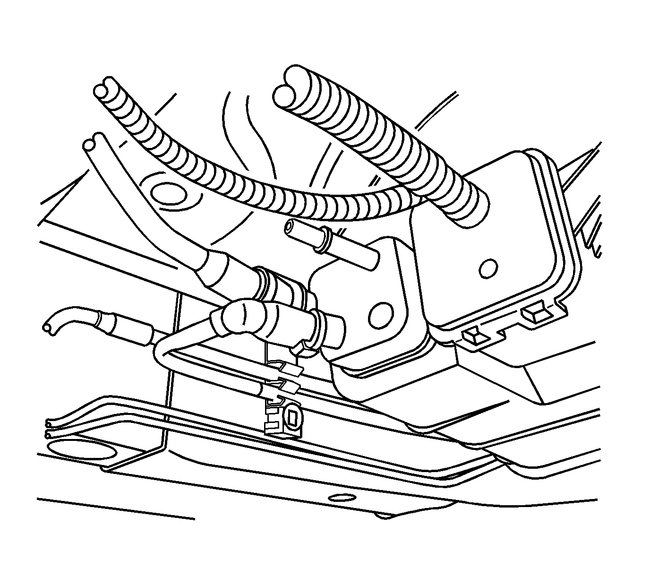

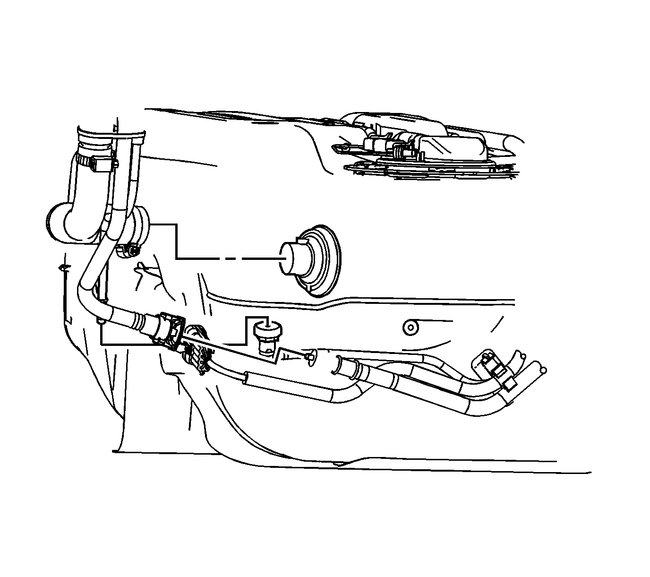

Pic 3

8. Remove the fuel filler pipe, EVAP vent hose, and fresh air hose from the fuel tank.

9. Disconnect the chassis fuel supply line from the tank.

CAUTION: Whenever fuel lines are removed, catch fuel in an approved container. Container opening must be a minimum of 300 mm (12 in) diameter to adequately catch the fluid.

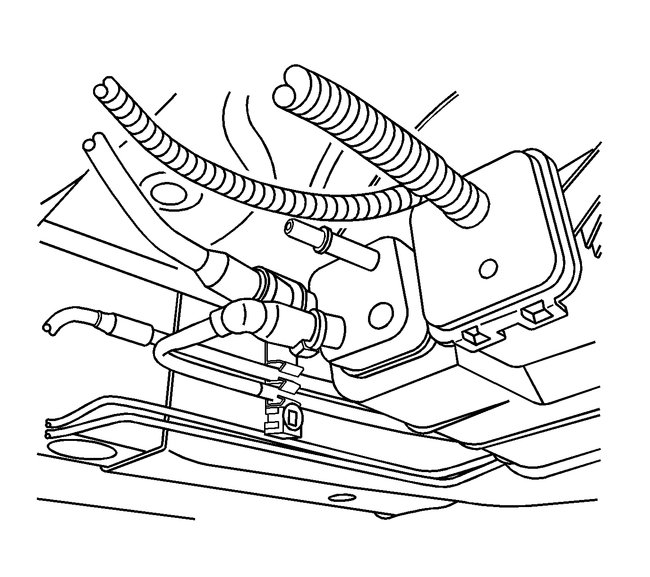

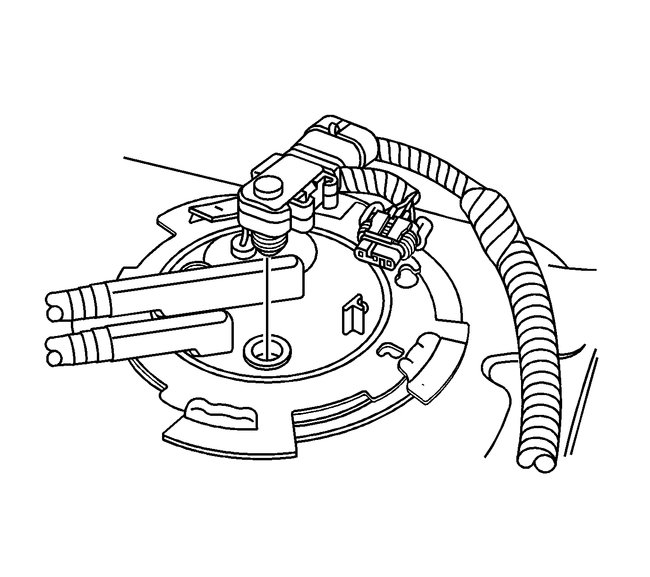

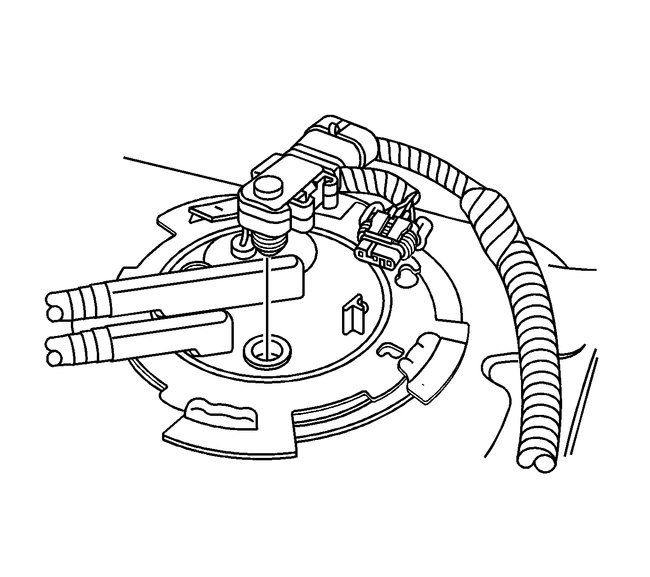

10. Disconnect the electrical connectors:

1. Fuel tank electrical connectors

2. EVAP solenoid electrical connector

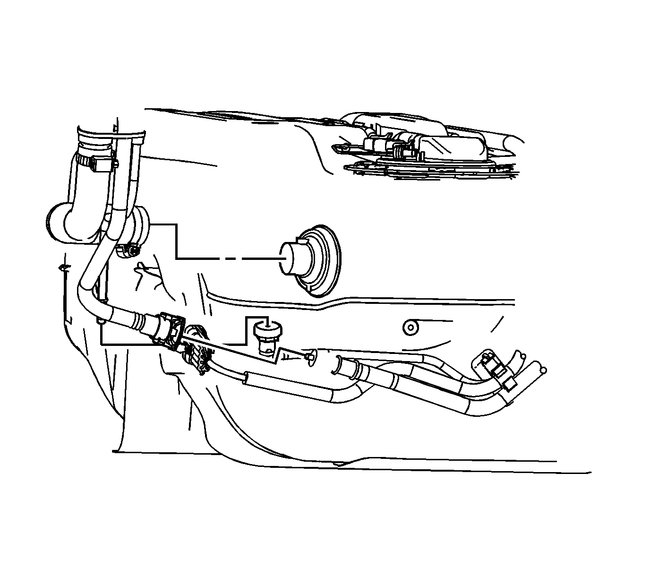

pic 4

11. Support the fuel tank.

NOTE: Do not bend the fuel tank straps. Bending the fuel tank straps may cause damage to the straps.

IMPORTANT: Do not disassemble the RDM. It is not necessary to touch the RDM for fuel tank removal.

12. Remove the fuel tank strap bolts and fuel tank straps.

13. Lower the fuel tank from the underbody of the vehicle.

14. Remove the fuel tank module assemblies.

INSTALLATION PROCEDURE

1. Install the fuel tank module assemblies.

Pic 5

2. Install the fuel tank heat shield and fuel tank assembly into the vehicle.

3. Install the fuel tank straps and tighten the bolts.

NOTE: Refer to Fastener Notice in Service Precautions.

Tighten the fuel tank strap-to-body bolts to 25 N.M (18 lb ft).

Pic 6

4. Install the fuel filler pipe, EVAP vent, and fresh air hoses to the fuel tank.

5. Connect the electrical connectors:

1. Fuel tank electrical connector

2. EVAP solenoid electrical connectors

6. Tighten the hose clamp on the filler pipe-to-fuel tank connecting hose.

Tighten the fuel fill neck-to-fuel tank clamp to 5 N.M (44 lb in).

Pic 7

7. Connect the EVAP canister vent and fresh air hoses to the fuel tank hoses.

8. If equipped, install the propeller shaft.

Pic 8

9. Install the rubber exhaust hangers.

10. Lower the vehicle.

11. Fill the fuel tank with gasoline.

12. Connect the negative battery cable.

13. Prime the fuel system:

1. Cycle the ignition ON for 5 seconds and then OFF for 10 seconds.

2. Repeat the previous step twice.

3. Crank the engine until it starts. The maximum starter motor cranking time is 20 seconds.

4. If the engine does not start, repeat steps 13.1-13.3.

_____________________________________________

Sensor replacement.

FUEL TANK PRESSURE SENSOR REPLACEMENT

REMOVAL PROCEDURE

1. Remove the fuel tank.

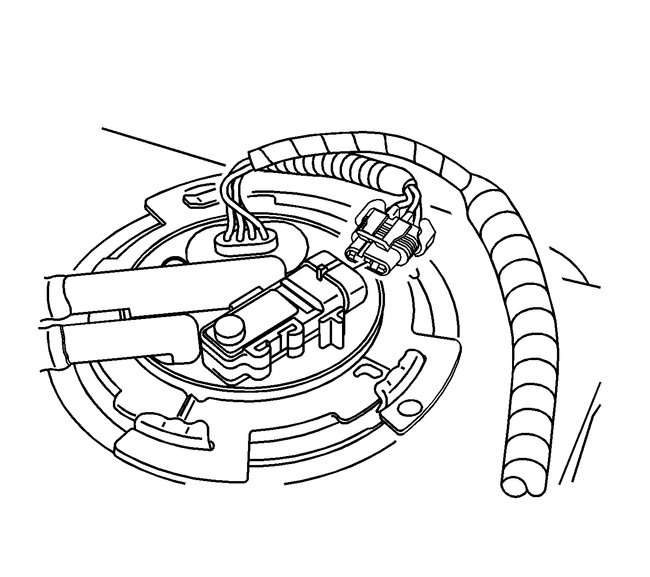

Pic 9

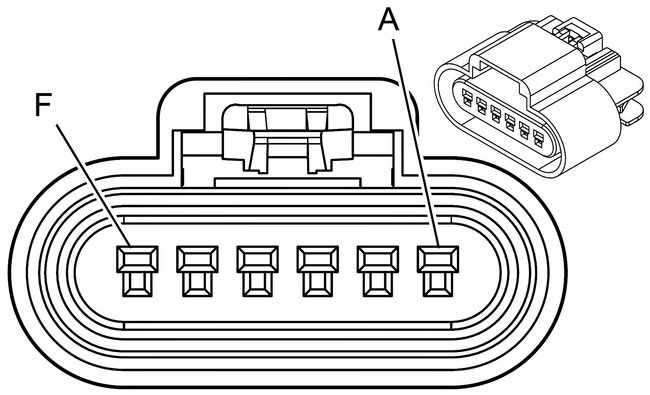

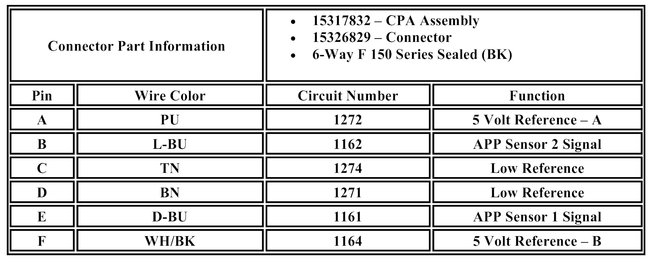

2. Disconnect the fuel pump module harness electrical connector from the fuel tank pressure sensor.

Pic 10

3. Position 2 flat-bladed screwdrivers, one on each side of the sensor, near the vacuum port.

4. Carefully use the screwdrivers to lift and release the sensor from the fuel pump module.

INSTALLATION PROCEDURE

pic 11

1. Install the fuel tank pressure sensor to the fuel pump module assembly. Ensure that the sensor grommet is fully seated to the pump module.

Pic 12

2. Connect the pump module electrical connector to the fuel tank pressure sensor.

3. Install the fuel tank.

_______________________________________________

I hope this helps. Let me know if you have questions and if you get it going.

Take care,

Joe

Images (Click to make bigger)

Friday, May 17th, 2019 AT 7:32 PM