Hi Joe,

My apologies for the reply to an old message, but you've helped me out a good bit in the past on this Ford truck that I wanted to ask you specifically about an issue with the Ford truck. Figured if I asked a general question I may or may not get you so decided to go this route. If it's not appropriate then I completely understand, and I'll simply post a new question.

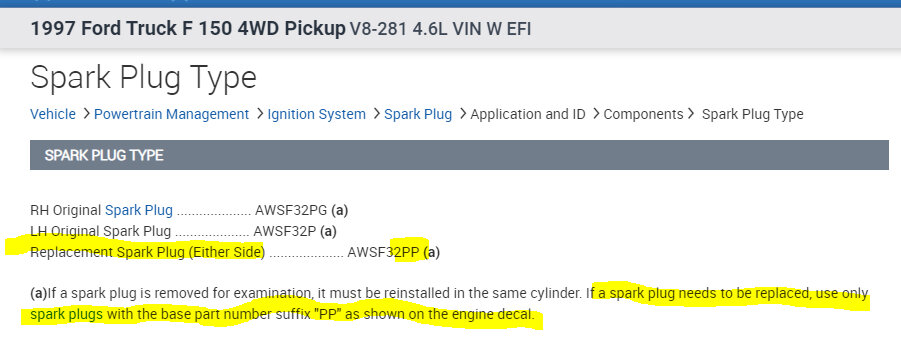

Any event, same 1997 F150 4.6 V8.

The # 4 spark. It seems the hex has been rounded off such that I can't get a 5/8 socket on it. Does nothing but spin around the base of the plug. Tried a 15MM. Same thing. I tried a deep well extractor socket made by Irwin and that won't work either. Even tapped the 5/8 extractor socket down onto the plug a bit but it still would not catch the plug enough to get it out. Crazily this particular plug has prob been in there for 15 years or so. Mainly because the last two times I've changed the other plugs this plug just would not come out, and in trying to get it out have evidentially rounded the hex on the plug so I left it until the plug just gave out a few weeks ago. No doubt the plug is seized into the well. I already tried soaking the well with PB blaster for a few days, and even let the truck run to head that hole up a bit. No luck.

Would you by chance have any out of the ordinary way that I might be able to get this plug out short of removing the head? Needless to say, this plug is in the absolute worst possible place, with very limited room. Any tips or tricks that might work would be appreciated. If nothing works, I may just drive it on 7 cylinders when I need it lol.

Also, I did buy a bore scope and took a picture of the plug. And it looks like there might be something stuck next to the plug that is preventing the socket from fitting fully onto the hex. I've included the picture. Maybe you can advise on what it might be or if it's anything at all. Thanks again for any advice.

Images (Click to make bigger)

Thursday, August 24th, 2023 AT 4:52 PM