Hello,

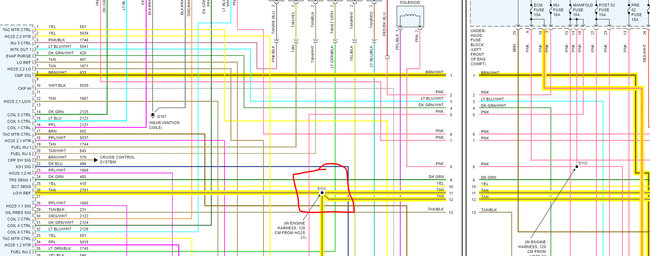

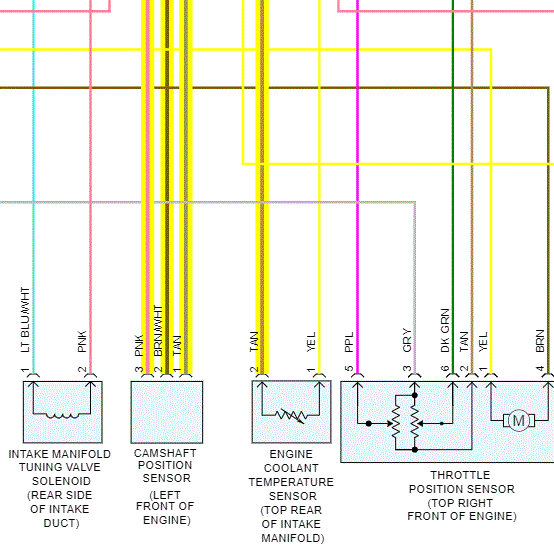

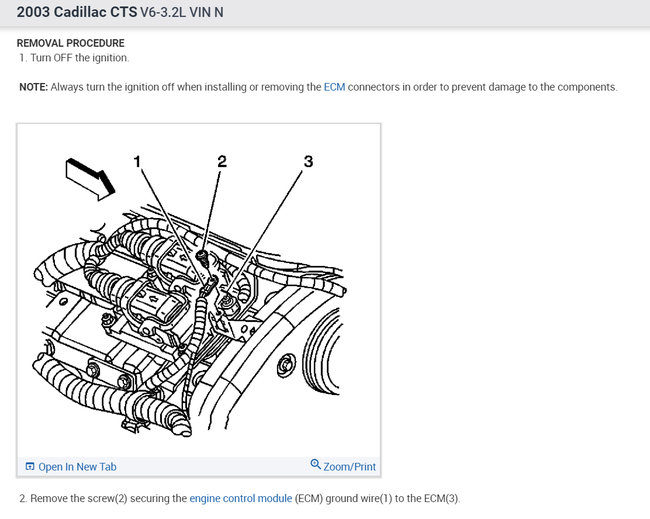

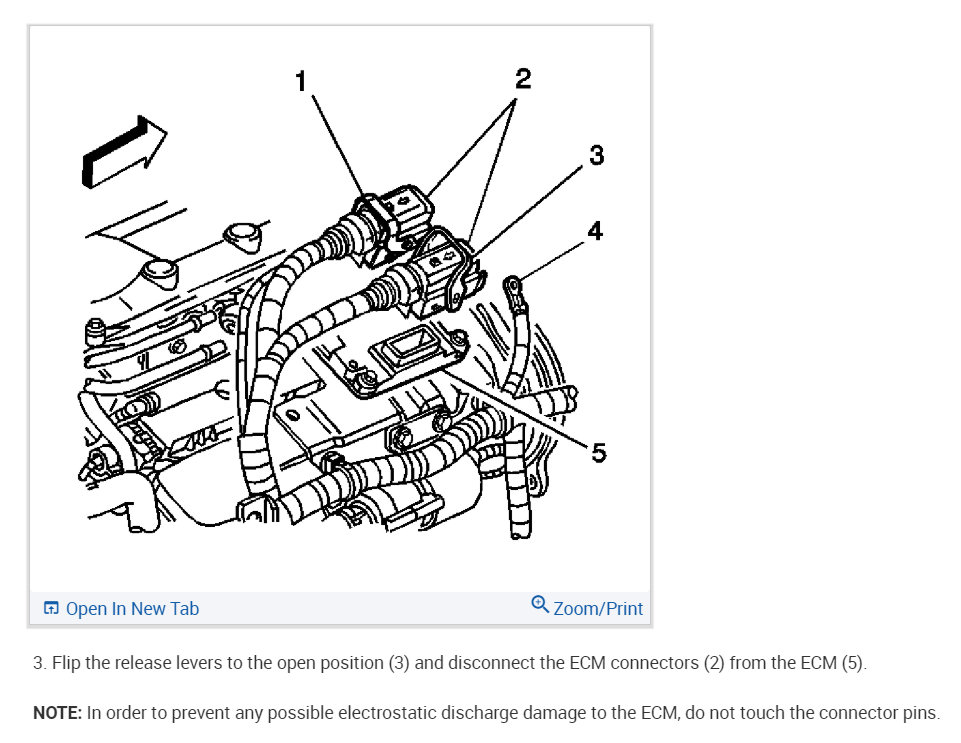

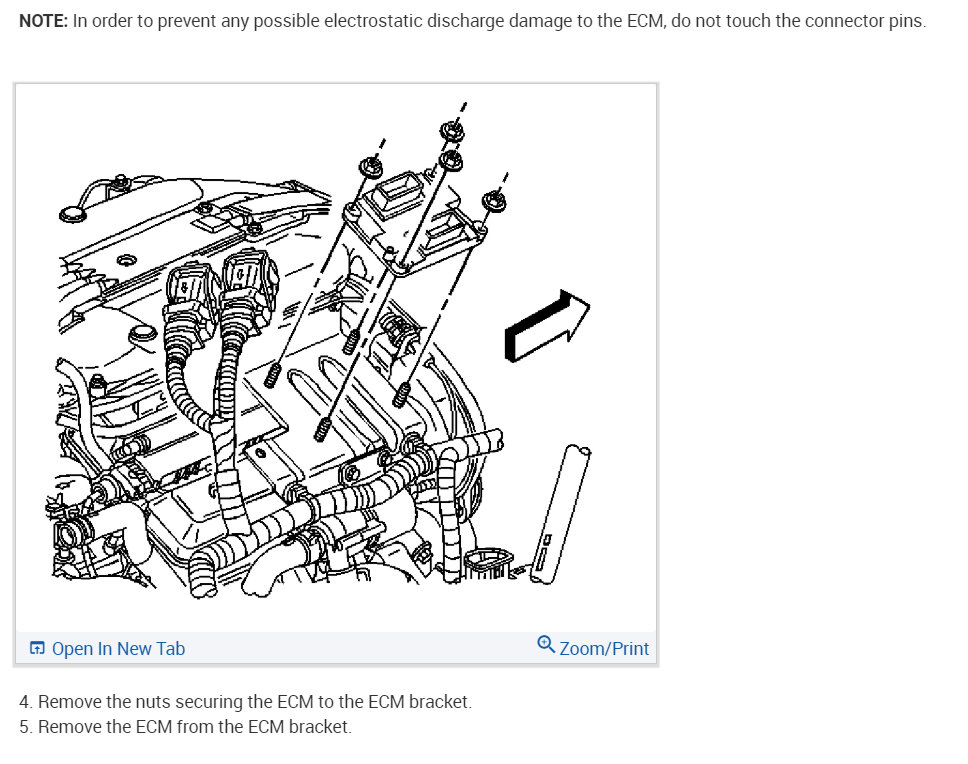

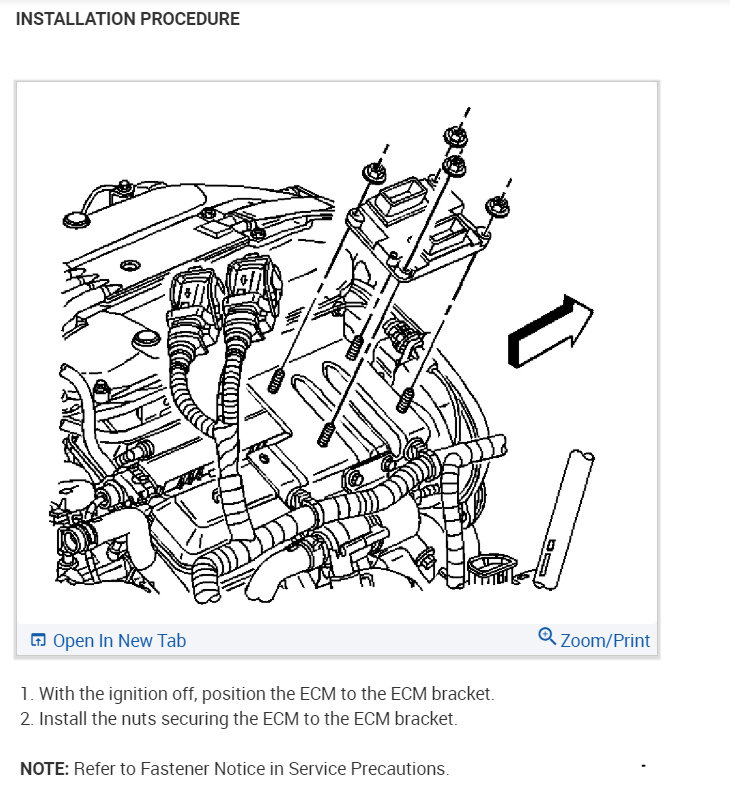

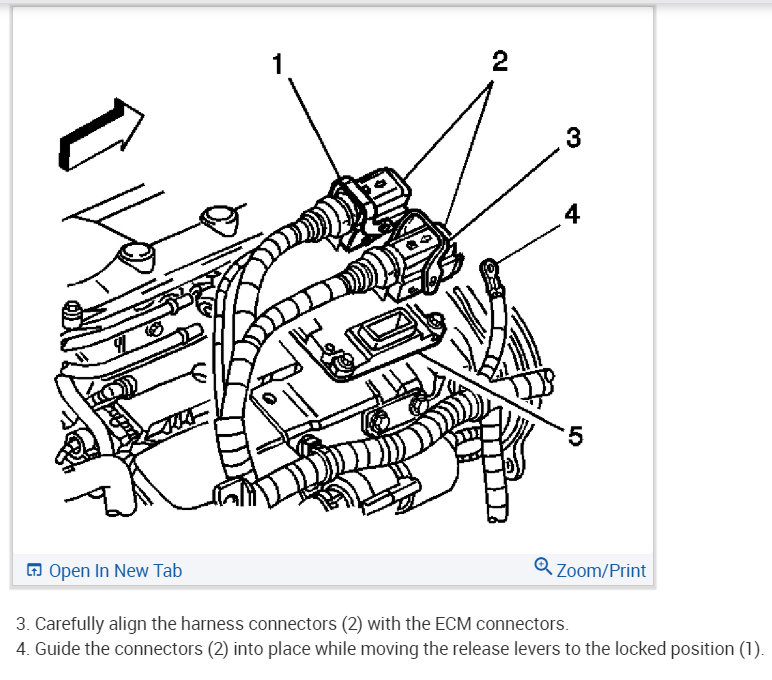

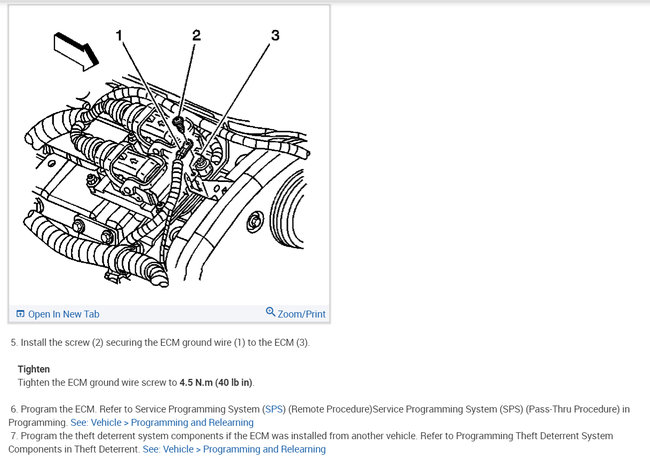

Yes, it sounds like the drivers inside the PCM have gone bad, probably due to the shorted wiring. I would try a rebuild unit please give your VIN number when ordering. Here are the instructions on how to replace the unit in the diagrams below. Yours should have this done before you get it.

Before Programming a Control Module (shop)

IMPORTANT: DO NOT program an existing control module with the identical software/calibration package. This procedure is not a short cut to correct a driveability condition. This is an ineffective repair. A control module should only be programmed when the following occurs:

- When a service procedure instructs you to replace the control module. The service part control module does not contain operating software or calibrations.

- General Motors Corporation releases an updated software/calibration package.

Ensure that the following conditions are met before programming a control module:

- Vehicle system voltage:

- There are no charging system concerns. All charging system concerns must be repaired before programming a control module.

- The battery voltage is greater than 12 volts but less than 16 volts. The battery must be fully charged before programming the control module.

- A battery charger is NOT connected to the vehicles battery. Incorrect system voltage or voltage fluctuations from a battery charger may cause programming failure or control module damage.

- Turn OFF or disable any system that may put a load on the vehicles battery. Turn OFF or disable systems such as:

- Daytime running lights (DRL). Applying the parking brake, on most vehicles, disables the DRL system.

- Heating, ventilation, and air conditioning (HVAC) systems

- Cooling System fans, etc.

- The ignition switch is in the proper position. The scan tool prompts you to turn ON the ignition, with the engine OFF. DO NOT change the position of the ignition switch during the programming procedure unless instructed to do so.

- All tool connections are secure:

- The RS-232 cable

- The connection at the DLC

- The voltage supply circuits

- The OBPA

- DO NOT disturb the tool harnesses while programming. If an interruption occurs during the programming procedure, programming failure or control module damage may occur.

- If you are performing the pass-through programming procedure using a notebook computer without the power cord, ensure that the internal battery is fully charged.

After Programming a Control Module

The powertrain may operate slightly different after a control module software/calibration update. Operating the powertrain through various driving conditions allows the control module to re-learn certain values. The control module must re-learn the following after a software/calibration update:

- Fuel trim correction

- Idle air control (IAC) learned position

- Automatic transmission shift adapts

Other learned values only re-learn by performing a service procedure.

If a control module is replaced the following service procedures may need to be performed:

- The crankshaft variation learn procedure

- The engine oil life reset procedure

- The idle learn procedure

- The inspection/maintenance complete system set procedure

- The vehicle theft deterrent password learn procedure

- The throttle position (TP) sensor learn procedure

Check out the diagrams (below). Please let us know what happens.

Images (Click to make bigger)

SPONSORED LINKS

Tuesday, April 28th, 2020 AT 7:46 PM