_________________________

1995 Saturn Sedan L4-1.9L DOHC VIN 7

Engine Controls - DTC's 26, 32 & Flag 27 Manual Updates

Vehicle Powertrain Management Technical Service Bulletins Engine Controls - DTC's 26, 32 & Flag 27 Manual Updates

ENGINE CONTROLS - DTC'S 26, 32 & FLAG 27 MANUAL UPDATES

BULLETIN NO: 96-T-08

ISSUE DATE: January, 1996

GROUP/SEQ. NO: Engine-01

CORPORATION NO: 686001

SUBJECT:

Diagnostic Service Information on PCM/EC DTCs 26 and 32, and Information Flag 27

MODELS AFFECTED:

1991 - 1995 Saturns

PURPOSE:

The diagnostic flow carts for diagnostic trouble code (DTC) 26 and Information Flag 27, in the "1991-1994 Electronic Engine Controls Service Manual, " and for DTCs 26 and 32 and for Information Flag 27 in the "1995 Electronic Engine Controls Service Manual" have incorrect resistance specifications. Also, some of the resistance specifications under the "Diagnostic Aids" for these DTCs and Information Flags are incorrect.

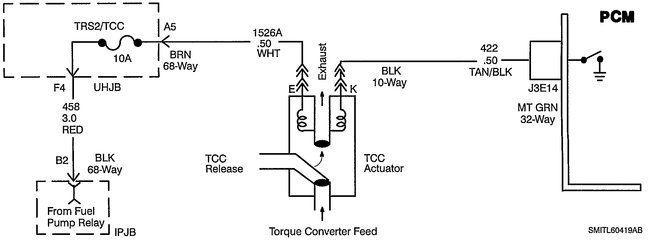

It is important to note that only a short or open in a solenoid, relay, bulb or related wiring or electrical connections can cause the PCM to set DTCs 26 or 32, or Information Flag 27. A resistance in the output circuits between 5 and 10,000 ohms will not cause DTCs 26 or 32, or Information Flag 27.

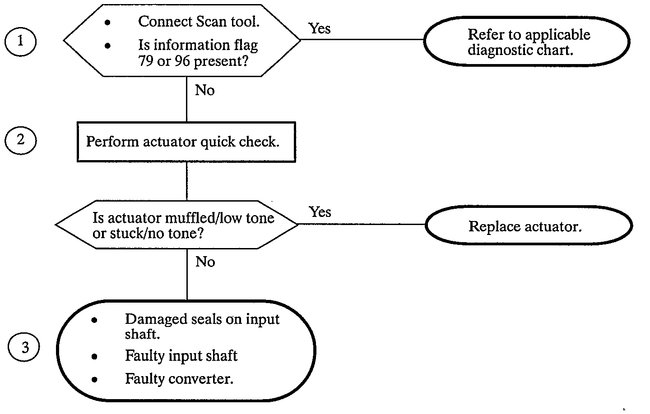

Beginning diagnosis with resistive measurements of the solenoid will likely result in mis-diagnosis. If the fault is present during diagnosis, follow the diagnostic flow chart for the DTC or Information Flag. If the fault is intermittent, attempt to test the quad driver module (QDM) outputs under similar operating conditions as represented by the malfunction (MALF) history records, stored in the PCM. Exercise the QDM with "Special Test" function in the portable diagnostic tool (PDT) or service stall system (SSS).

If a solenoid or relay is not within the specifications stated under the "Diagnostic Aids" for the DTC or Information Flag, it does not mean that the solenoid or relay was the reason the DTC or Information Flag was set. It could mean that the solenoid or relay operates sluggishly or too rapidly, but unless the solenoid or relay opened or shorted, it cannot have caused the DTC or Information Flag to have been set in PCM memory.

Refer to the chart following and make the corrections in the service manuals as noted. 1991-1994 Electronic Engine Controls Service Manual

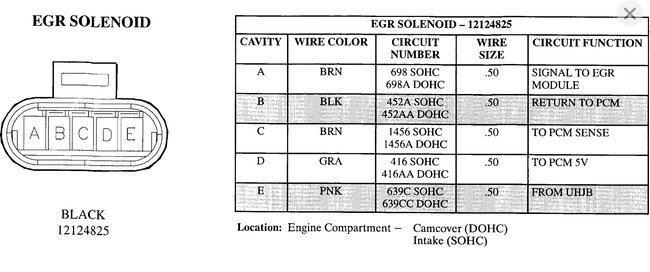

Page ENEC 70 (DTC 26), under "Diagnostic Aids, " change:

- EGR solenoid resistance specification from 37-44 ohms to 20-50 ohms.

- EVAP canister purge solenoid resistance specification from 22-42 ohms to 20-50 ohms.

Page ENEC 72 (DTC 26), in first box of flow chart, change:

- EGR solenoid resistance specification from 37-44 ohms to 5-10,000 ohms.

- EVAP canister purge solenoid resistance specification from 22-42 ohms to 20-50 ohms.

Page ENEC 120 (Information Flag 27), under "Diagnostic Aids, " change:

- EGR solenoid resistance specification from 37-44 ohms to 20-50 ohms.

- EVAP canister purge solenoid resistance specification from 22-42 ohms to 20-50 ohms.

1995 Electronic Engine Controls Service Manual

Page ENEC 68 (DTC 26), under "Diagnostic Aids, " change:

- Linear EGR solenoid resistance specification from 7-9 ohms to 7-10 ohms.

- EVAP canister purge solenoid resistance specification from 22-42 ohms to 20-50 ohms.

Page ENEC 69 (DTC 26), in the flow chart box "is the resistance of the EVAP canister purge solenoid between 22-42 ohms?" Change resistance specification to 20-50 ohms.

Page ENEC 72 (DTC 32), under "Diagnostic Aids, " change:

- Linear EGR solenoid resistance specification from 7-9 ohms to 7- 10 ohms.

- EVAP canister purge solenoid resistance specification from 22-42 ohms to 20-SO ohms.

Page ENEC 114 (Information Flag 27), under "Diagnostic Aids, " change;

- Linear EGR solenoid resistance specification from 7-9 ohms to 7-10 ohms.

- EVAP canister purge solenoid resistance specification from 22-42 ohms to 20-50 ohms.

Page ENEC 115 (Information Flag 27), in the flow chart box "Is the resistance of the EVAP canister purge solenoid between 22-42 ohms?" Change resistance specification to 20-50 ohms.

Joe

SPONSORED LINKS

Was this helpful?

Yes

No

Sunday, March 15th, 2020 AT 8:40 PM