Good afternoon

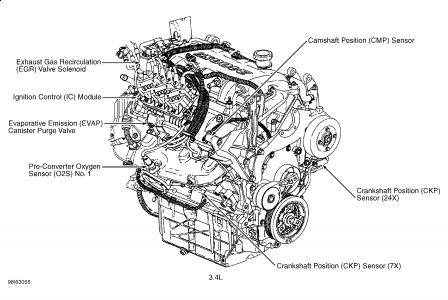

There are two for this model. I have attached pictures and procedures for both.

Do you have a code for this repair?

Roy

This is the one on the back of the motor

REMOVAL PROCEDURE

1. Turn the steering wheel fully to the left.

CAUTION: Refer to Caution in Service Precautions.

2. Raise vehicle on hoist.

3. Disconnect sensor electrical connector.

4. Remove bolt/screw.

5. Remove sensor from engine.

6. Inspect for the following:

6.1. Inspect the sensor for wear, cracks, or leakage. Replace the O-ring if necessary.

6.2. Lubricate the new O-ring with clean engine oil before installing.

This is the one behind the crankshaft pulley in the front of the motor

REMOVAL PROCEDURE

CAUTION: Refer to Battery Disconnect Caution in Service Precautions.

1. Disconnect the negative battery cable.

2. Remove the serpentine drive belt from crankshaft pulley.

CAUTION: Refer to Caution in Service Precautions.

3. Raise the vehicle on hoist.

4. Remove the crankshaft harmonic balancer retaining bolt.

5. Remove the crankshaft harmonic balancer.

6. Note the routing of sensor harness before removal.

7. Remove the harness retaining clip with bolt (1).

8. Remove the sensor electrical connector.

9. Remove the sensor bolts (2).

10. Remove the sensor.

If you replace the one behind the crank pulley, it has to have a relearn procedure done with a scan tool.

The crankshaft position system variation compensating values are stored in the PCM non-volatile memory after a learn procedure has been performed. If the actual crankshaft position system variation is not within the crankshaft position system variation compensating values stored in the PCM, DTC P0300 may set. Refer to Diagnostic Aid for DTC P0300.

The Crankshaft Position System Variation Learn Procedure should be performed if any of the following conditions are true:

DTC P1336 is set.

The PCM has been replaced.

The engine has been replaced.

The crankshaft has been replaced.

The crankshaft harmonic balancer has been replaced.

The crankshaft position sensor has been replaced.

IMPORTANT: The scan tool crankshaft position system variation learn function will be inhibited if engine coolant temperature is less than 70°C (158°F). Allow the engine to warm to at least 70°C (158°F) before attempting the crankshaft position system variation learn procedure.

The scan tool crankshaft position system variation learn function will be inhibited if any powertrain DTCs other than DTC P1336 are set before or during the crankshaft position system variation learn procedure. Diagnose and repair any DTCs if set.

The crankshaft position system variation learn function will be inhibited if the PCM detects a malfunction involving the camshaft position signal circuit, the 3X reference circuit, or the 24X reference circuit.

If the scan tool indicates a problem with the Cam signal, refer to DTC P0341 Camshaft Position (CMP) Sensor Performance.

If the scan tool indicates a problem with the 3X crank signal, refer to DTC P1374 3X Reference Circuit.

If the scan tool indicates a problem with the 24X crank signal, refer to DTC P0336 24X Reference Signal Circuit.

1. Depress and hold the service brake pedal.

2. Block the drive wheels.

3. Ensure the hood is closed.

4. Start the engine and allow engine coolant temperature to reach at least 70°C (158°F).

5. Turn OFF the ignition switch.

6. Select the crankshaft position variation learn procedure from the scan tool special functions list.

7. Follow the instructions displayed on the scan tool. If the procedure is terminated, refer to Important above for instructions.

8. Observe DTC status for DTC P1336.

9. If the scan tool indicates that DTC P1336 ran and passed, the crankshaft position system variation learn procedure is complete. If the scan tool indicates DTC P1336 failed or not run, check for other DTCs. If no DTCs

Images (Click to make bigger)

Sunday, September 30th, 2018 AT 12:52 PM