I had to edit this a little, my first two pictures did not show up when I submitted, they will probably wind up as the last two, I am sure you will figure it out.

This is how you replace a distributor. I am going to show you the way I do it, then give you a couple of links of someone else explaining and showing. (You might see why I do it in slow motion)

Xdistributor (this word helps me search for this quickly, if I need to copy and paste some or all of this to someone else!)

Using the starter to bump the engine to find the compression stroke works fine with a seasoned auto guy. It is too easy to "overrun" your stroke and not realize it if you are not familiar with the procedure.

Let's do it in slow motion, it is more accurate in my opinion.

Hide your keys, chock your wheels, put the transmission in neutral.

Remove number one spark plug.

Stick it back in and only screw it in barely by two threads. This will allow compression to "hiss" by it (some remove the plug and stick their thumb in the hole - this scares folks!).

Remove spark plug number one.

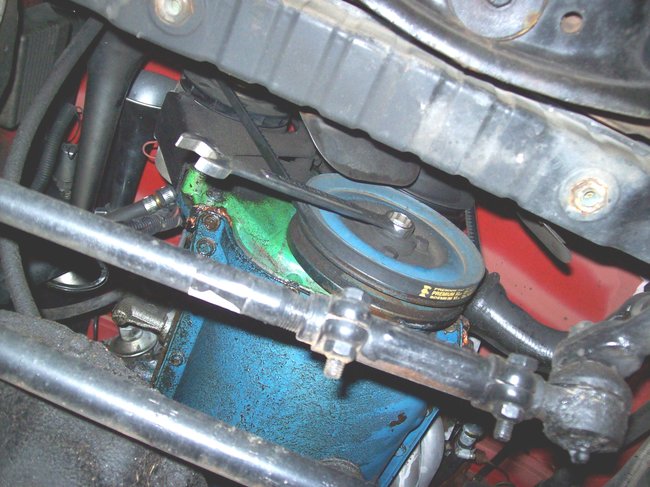

From the front, a CJ's engine turns clockwise when running, this is how we will turn it "by hand" using a ratchet or wrench on the harmonic balancer bolt (picture number one below).

As you rotate (being this is a four stroke engine, you may have to turn two full revolutions to find the compression stroke) eventually you will hear a "louder" hiss from the loose number one plug. (you may hear faint hisses from the other cylinder leaking past the rings)

Stop!

You are at the beginning of the compression stroke.

Number one piston is still coming up on this stroke, our goal is to get it to the top. This is called "top dead center" or TDC.

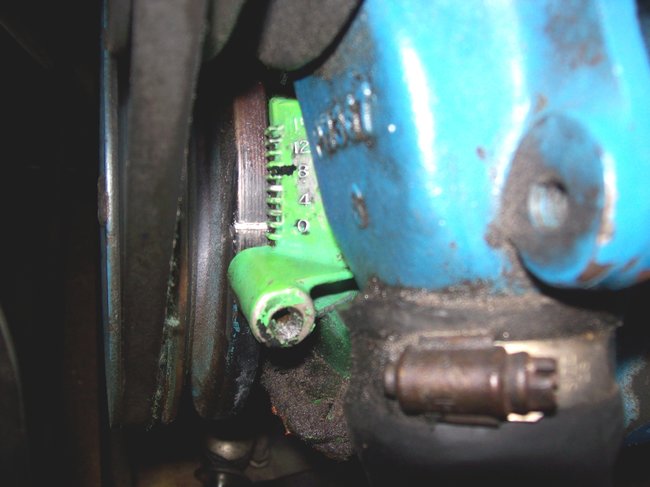

Ever so slowly continue to rotate CW, until your timing mark is on "zero". This will be less than a half a turn from where you heard the hiss (white chalk in groove is lined up with "zero"(if more than half a turn, start over!) (See my picture number two)

If you miss the stroke or pass your marks, and then hit your marks (you are most likely on the exhaust stroke (it will not hiss). The other "up stroke", 180 degrees off. Start over, we want TDC!

Back to slow motion, our timing line is on zero, we should be dead on TDC.

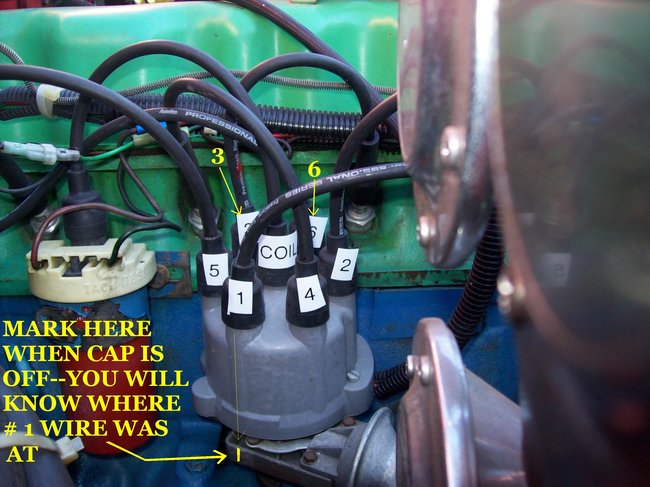

Take off your distributor cap, look at the rotor button, is it pointing to where number one spark plug wire is located?

(This really does not matter as long as you put number one spark plug wire at that location and then follow the firing order sequence in a clockwise manner from that point on.)

I like to arrange mine as it is shown in diagrams (textbook)(later on in time, using the diagram would get you right if the wires were all removed).

While at TDC, (not moving the crank at all!) you can remove or pick up the distributor out of the cam gear, rotate the rotor button to the desired position and sit it back down. Remember when it engages the cam gear it will "twist" a little. Allow for the twist!

To go along with this, the oil pump drive is on the flat screwdriver end of the distributor shaft. It is a big slot (look into the distributor hole).

If you move the rotor button. You will also have to use a flat screwdriver to move the oil pump shaft a little so that the end of the distributor will go into that slot. Otherwise the distributor will not sit all of the way down! Sometimes this is tricky, Do not force it! Small "tweaks" will finally let it sit down, remember the "twisting action' as you drop it in might fool you as to which way to face the oil pump slot!

The 258 firing order (plug wires) is 1-5-3-6-2-4.

Below, third picture is textbook distributor set up. (Note the mark, where the rotor button should point when trying to stay "textbook")

After the distributor has been installed or even loosened and moved, you will need to use a timing light and a dwell/tachometer to set you timing perfect, the TDC deal is to get the valve train timed with the distributor, it may get it to run or run enough to time it by ear, it does not do your "final" timing setting.

You will need a timing light and a dwell/tachometer (or similar ones to mine). Many times these are considered "dinosaurs" and can be found real cheap at a pawn shop/flea market/ etc. See last picture.

When you get to this point, I can help you tweak in the distributor and carburetor final adjustments. I have more CJ fix pictures!

Here is a review on finding TDC and installing the distributor.

CLASS 1

http://www.youtube.com/watch?v=5a2X9mSSlQY

CLASS 2

http://www.youtube.com/watch?NR=1&v=FHX1yXVyIMg&feature=endscreen

Your turn,

The Medic

Images (Click to make bigger)

Saturday, June 30th, 2018 AT 3:04 PM