A fuel injector is responsible for allowing fuel into the engine and is controlled by the PCM as part of the fuel injection system. Fuel pressure supplied by the fuel pump is metered by the duty cycle of the computer which varies by engine load. This guide will show you how to check the trigger (ground) signal from the PCM, power circuit and the operation of the injector itself. To test the injector signal from the computer a test light works best. You will need a voltmeter to check resistance through the injector. Fuel maybe present during testing so the usual fire precautions are necessary. Use protective gloves and eye wear for safety. Test for FI systems only.

Fuel injector Testing

- Observe audible clicking confirming injector operation

- Check trigger signal output from the PCM

- Confirm the injector has power

- Test the coil windings resistance using a volt meter

- Confirm injector valve operation

- Inspect the injector casing for leaks

- Check flow and spray pattern

Let's Get Started

Simple Test

Start the engine and allow it to idle. Using a long metal rod like a screwdriver

touch the end of the screwdriver to the injector. Gently lay an ear to the opposite

end of the rod or handle to observe an audible clicking sound to confirm the injector

is working.

Injector Circuit Power Test

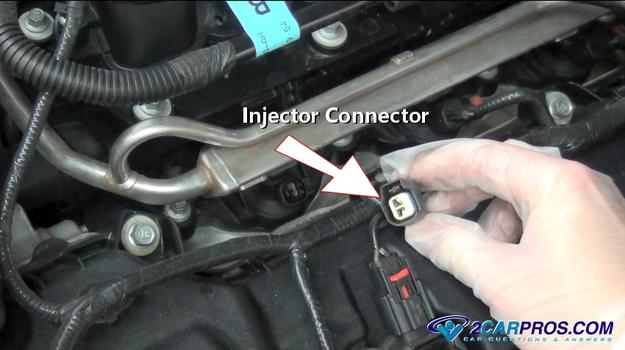

With the key in the on position use a

test light or

voltmeter connected to the negative

side of the battery. Gently probe both sides of the injector wiring connector, one

of the wires should react by registering around 12 volts on the meter or illuminating

the test light. If neither wire reacts test the fuel injector fuse in the PDC. If

the fuse is okay a fuel injection wiring diagram is needed to help

trace the wire and repair the connection.

Seal test points with a small dab of silicone rubber once testing is complete.

Injector Ground Trigger Test

The PCM closes the

injector circuit to trigger the injector operation. For this a test light works

best to observe the pulse produced by the PCM. Attach the test light lead to the

positive side of the battery and have a helper start or crank the engine. Probe

the opposite side of the injector connector from the power circuit, you should observe

the test light flicking which will respond to engine RPM/Load. If the engine is

running and no pulse is observed suspect a bad wiring connection or a failed PCM

injector driver which will warrant a PCM replacement. A shorted injector can hinder

the injector driver operation for additional injectors, unplug all injectors and

re-test the signal. If pulse returns plug the injectors back in one at a time until

the pulse fails then replace the shorted injector. If the

engine is not running check the

crankshaft angle sensor

which the computer uses to open the injectors (Note: A failed crankshaft angle sensor

will not set a trouble code in most cases).

Fuel Injector Winding Test (key off)

Using a voltmeter, adjust the setting to ohms. This test can be performed with

the injector installed or uninstalled.

Remove the injector electrical connector

This will expose the injector electrical terminals.

Connect the voltmeter leads to the terminals, the polarity of the leads is irrelevant.

This test gives a baseline ohm reading of all injectors, a service manual also has

this information. Most injector readings should range between 11 and 14 ohms. Fuel

injectors should be tested cold unless otherwise specified, temperature variances

will change the readings. If the test shows high resistance or an open circuit the

injector needs replacement.

For this test the injector

must be removed. Inspect the injector housing for leaks and electrical connectors

for corrosion. The valve and spray pattern is the most important part of testing a fuel injector.

Valve testing can be done with the injector still installed using a fuel pressure

gauge while hot wiring the fuel pump to stay on. Carefully attach a 12 volt power

(power and ground) source to the injector, you should be able to see the gauge fluctuate

as you connect and disconnect the circuit if the injector valve is working and not

plugged. To check the injector spray pattern the injector must be removed. Attach pressurized

air to the injector inlet. Attach a 12 volt power and ground source to energize

the injector. Compressed air should be released from the outlet valve with traces

of fuel still remaining from the injector (use fire precautions). Observe the pattern

which should be robust, if the pattern is muted the injector should be replaced. Our certified technicians are ready to answer fuel injector

test questions for free. We hope you saved money and learned from this guide.

We are creating a full set of car repair guides. Please

subscribe to our 2CarPros YouTube

channel and check back often for new videos which are uploaded regularly.

Questions?