Introduction

The automotive engine computer, also known as the ECU, PCM or ECM (Engine control unit, Powertrain control module, Engine control module), is central to a vehicle’s performance, efficiency, and emissions control. This guide will provide an in-depth, step-by-step explanation of how an engine computer works, covering sensors, processing, outputs, and control strategies.

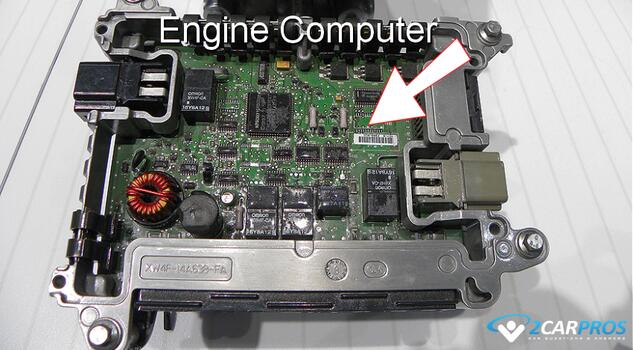

Overview of the Engine Computer

An automotive engine computer is programmed to process feedback data from various sensors and deliver electrical commands to various engine and transmission systems, think of this computer as a dedicated platform much like a Play Station or X box, designed for controlling key functions.

The engine computer relies on data from various sensors to monitor the engine's state. Key sensors include:

- Mass Air Flow (MAF) Sensor: Measures the amount of air entering the engine, helping the computer adjust the air-fuel mixture.

- Oxygen (O2) Sensor: Located in the exhaust system, it measures the oxygen content to help maintain the ideal air-fuel ratio.

- Crankshaft Position Sensor: Tracks the crankshaft’s position and speed to adjust ignition and fuel injection systems accurately.

- Camshaft Position Sensor: Measures the timing of the camshaft to help adjust the VVT system.

- Manifold Absolute Pressure Sensor: This sensor is located on the intake manifold and send feedback data related to engine load.

- Coolant Temperature Sensor: Monitors engine temperature, allowing the engine computer to adjust fuel delivery and ignition timing.

The engine computer's primary functions include:

- Fuel Injection Control: Determines the exact amount of fuel to inject based on load, temperature, and speed.

- Ignition Timing Control: Adjusts the ignition system spark timing to optimize combustion.

- Idle Speed Control: Maintains stable idle speed under different load conditions.

- Emission Control: Regulates exhaust gases to meet emission standards.

- Transmission Controls: Though some cars have a dedicated TCM (Transmission Control Module) the engine computer can help control shift times.

Adaptive Learning

This computer is a self learning device which has been programmed to adjust for driving conditions and the habits of the driver, this adaption is learned over time and will change the vehicle's operation such as transmission shift points.

Engine Computer Monitors

There are several system monitors that will run in the background of the computers operating system, this is done by using a predetermined program developed by the individual manufacturers. These monitors test and re-test certain systems such as the EVAP system, and catalytic converter performance to make sure they are functioning correctly. Monitors must cycle completely before the computer will give the car a clean bill of health. This is why you must drive the car a certain distance after clearing the codes before a smog or safety inspection can be performed.

Open and Closed Loop

Because an engine is cold when it first starts, the engine computer has two modes: "Open loop" which is a predetermined set of values that is used when the engine is cold, and "Closed loop" which allows the computer to make more fine adjustments once the engine and catalytic converter are at operating temperatures.

Trouble Codes

The engine control computer is programmed with fail safe systems that are meant to take over when a sensor or system has failed to allow the car to keep running. This failure triggers a diagnostic trouble code, (check engine light) which is designed to inform you of the problem and where to look for the error which is usually a sensor or mechanical problem.

Examples of common DTCs include:

- P0300: Random/Multiple Cylinder Misfire Detected

- P0171: System Too Lean (Bank 1)

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

Short and Long Term Trims

Automotive trims are adjustments made by the engine computer to the air-fuel mixture to maintain optimal engine performance, efficiency, and clean emissions. There are two primary types of trims:

Short-Term Fuel Trim (STFT): Represents immediate, real-time adjustments made by the engine computer to the fuel injection keeping the air-fuel ratio close to the ideal value. Negative trim (either in Short-Term Fuel Trim or Long-Term Fuel Trim) means that the ECU is reducing fuel because it has detected a rich condition in the exhaust.

Long-Term Fuel Trim (LTFT): Represents values over time which can change to optimize efficiency helping reduce the load on the short term trim making that correction more permanent.

Communication with Other Control Units

Today's car is a network of control modules, (computers) call a CAN BUS in which the engine computer is apart of along with the BCM (body control module) and TCM (transmission control module) to name a few.

Software Updates

Like most computers the operating problem must be updated which can fix firmware or software issues, this can be preformed at the dealer or service centers, in some newer vehicles, over-the-air (OTA) updates can be performed remotely.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel for additional car repairs.