Every vehicle must incorporate a steering mechanism which can direct the front

wheels in both right, and left directions. This is achieved using a series of ball

joints, tie rods, a steering box or rack, a steering wheel and column which are

attached. These steering components and

fluid level should

be inspected at regular service intervals. In this guide we should show you how

the steering system works, a steering system is divided into two separate parts,

the power assist portion and its mechanical parts.

What Goes Wrong?

As you can imagine there is a fair amount of force involved when steering a car. This can cause parts to wear which can produce abnormal sounds when driving especially at high speeds. Anytime steering components are replaced a wheel alignment is required. Use caution when moving a vehicle without the engine running or the power steering system not working, this can cause you to lose control of the vehicle because of the additional force it takes to turn the steering wheel.

Let's Jump In!

The steering wheel is used by the driver to control the vehicle which can either

be connected directly to a steering

box or rack and pinion. On some EV's the steering wheel is simply connected

to a position sensor which, in turn, tells a computer which way to direct the front

wheels and how far to move them via the electronic steering rack.

Designs include electronic steering controls which enable the computer to manage

the control of the vehicle to help avoid accidents by using proximity sensors. This

advanced steering system can also limit sudden movements by the driver at high speeds

with the help of an YAW sensor to further avoid crashes.

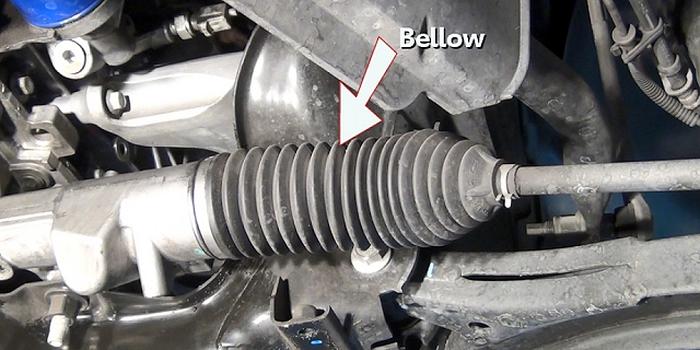

Rubber bellows are used to keep dust and dirt from affecting the steering operation,

these items are typically for rack and pinion style of steering units.

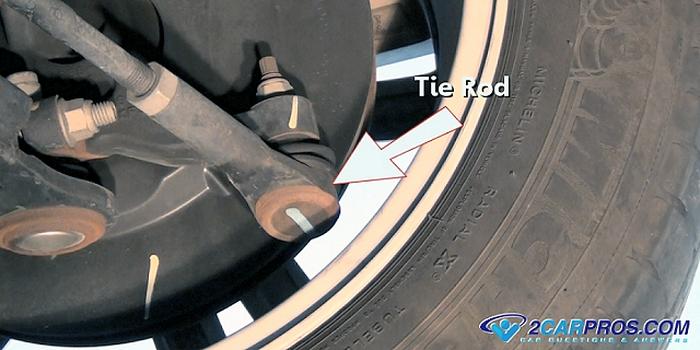

Tie rods are used to connect

the spindles (where the tires are mounted) to the steering assembly, this rod end

is filled with lubricant which helps the pivot points stay in good working order.

A tie rod end is also fitted with a dust cap to keep dirt from getting into the

joint.

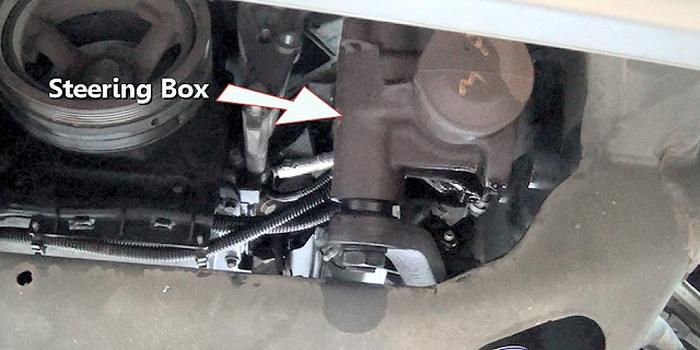

To control the front spindles on heavy duty applications a steering box is used

with a series of idler and pitman arms, center links and tie rod ends. A

worm gear box style of steering

system is constructed of two main parts, worm and selector shaft gears which are

attached to a pitman arm. An idler arm is located on the opposite side of the frame

from the steering box.

Power steering systems assist the driver's effort by using a hydraulic pressure

pump mounted to the engine which

is driven by a serpentine belt.

The image below shows what a typical power steering pump looks like. The fluid in

the system is held under pressure until the wheel is turned which releases the pressure

assisting in the steering action. This pump only provides steering assistance when

the engine is running.

These hydraulic systems must maintain proper fluid levels to operate correctly,

if fluid levels fall below minimum requirements the system will

howl and moan while air mixes with

the fluid, this condition can also lead to hard steering and pump failure. Levels

should be checked at each service interval, fluid leaks are common in these systems

such as a pressure hose

rupture.

Questions?

Our certified technicians are ready to answer your car repair questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.