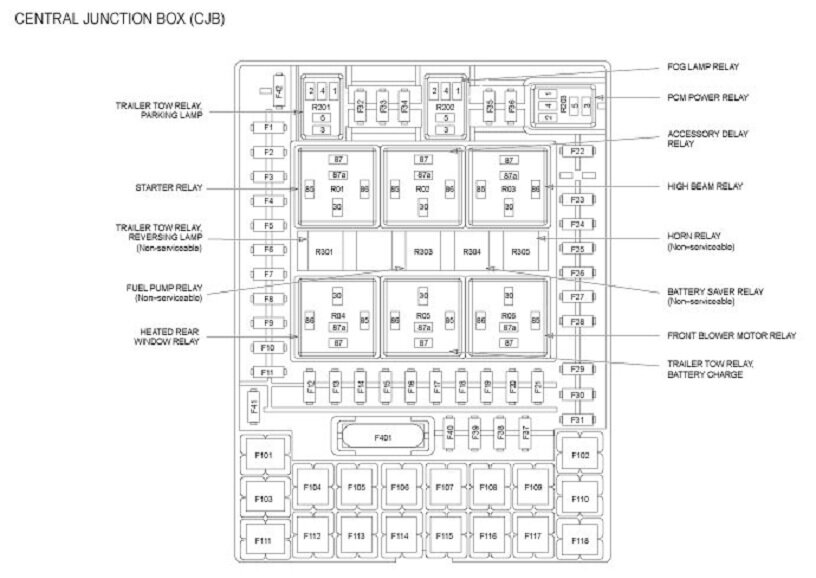

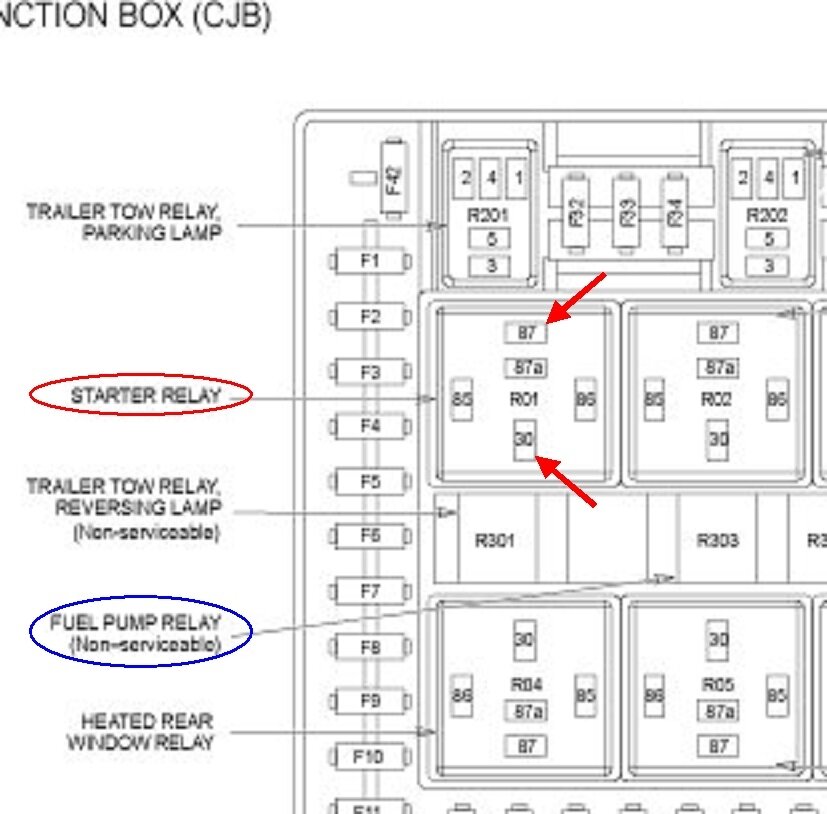

As usual, Ford does everything very differently from all other manufacturers. After an hour of searching, I'm starting to understand why this is so frustrating. It appears they combined the two fuse boxes, and used the names of both of them for the one box. For 2007 models they put it behind the right front kick panel next to the front passenger's feet. That keeps it away from salt and water spray. I hope it's the same for your 2006 model. I apologize for sending you in the wrong direction.

I understand exactly what you're trying to do, but this is still pointless. No professional would go through what you're trying to do. When you change oil, the new filter is full of air. That air can be compressed, so the oil pump has to move a large volume of oil before any gets to the bearings. With your new oil pump, it's going to be considerably easier for the pump to catch a prime.

The last engine I rebuilt was a Chrysler 318 c.I. With that one, it had a distributor and intermediate drive gear to remove, then I made a tool to drive the oil pump with an electric drill. To my surprise, I had oil spraying out all over within two or three seconds. That was starting with every oil passage void of oil. The problem today is most oil pumps are driven off the front of the crankshaft, so the only way to prime a new pump is to spin the crankshaft. Even though your engine has been sitting for a year, the crankshaft bearings are still going to have a heavy film of oil. That will be sufficient to keep them lubricated for the few seconds it takes to get new oil to them. This is no different than what they do with brand new engines on the assembly line. They start with Engine Assembly Lube on the bearings, and an over-full oil pan. The engines are started and test run, then sent to the assembly line to meet the vehicles.

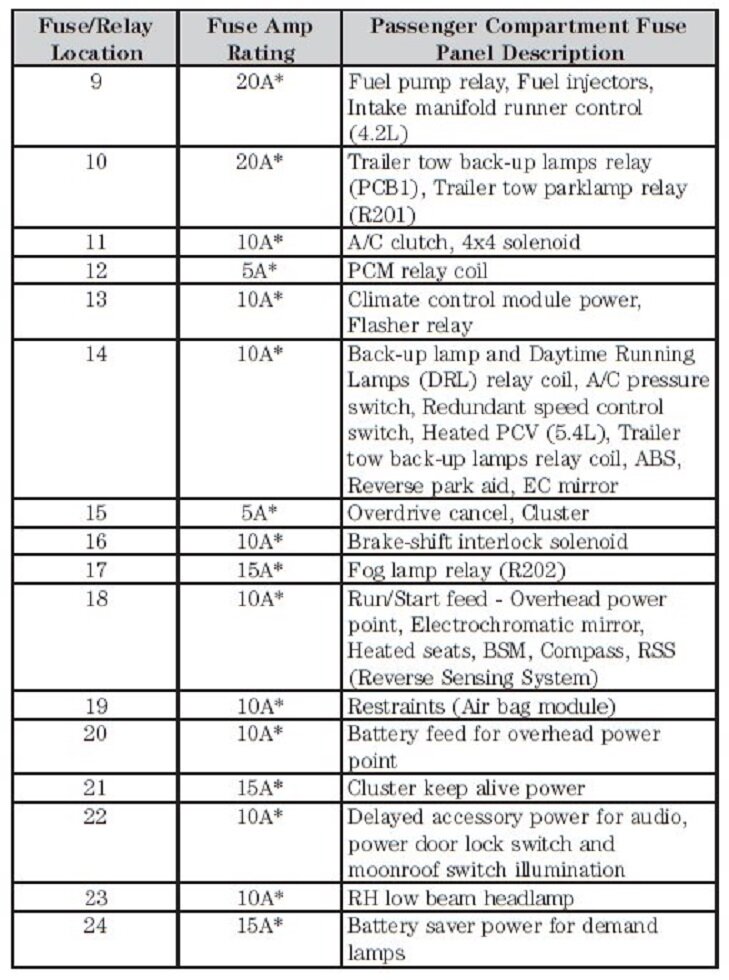

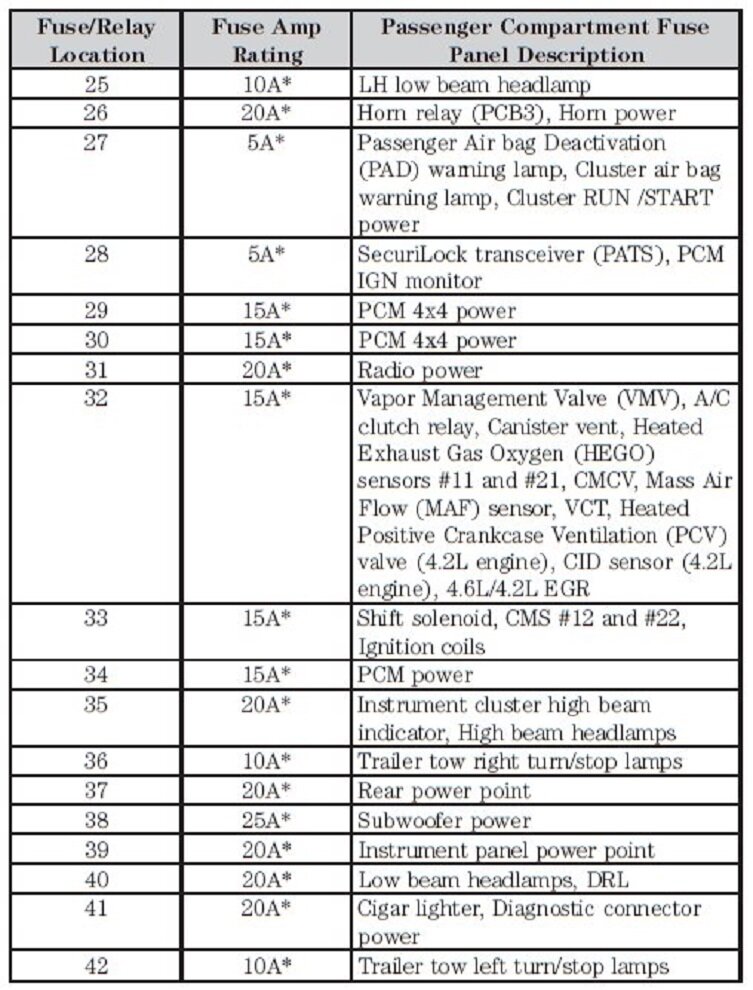

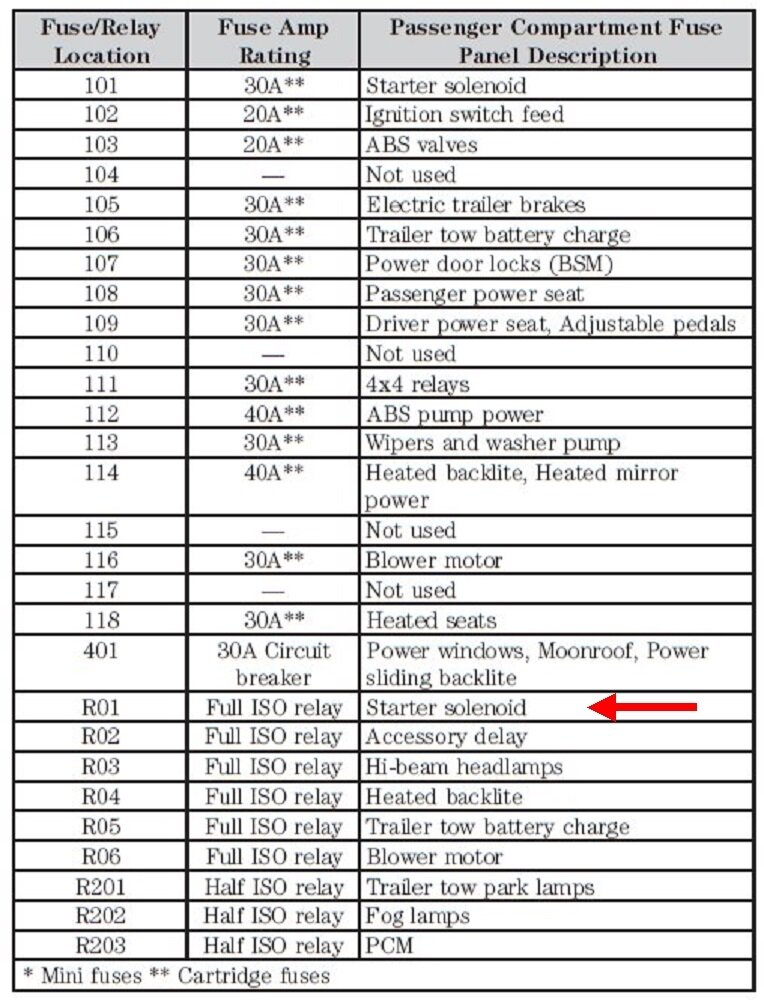

If you'd still feel better cranking the engine before starting, there are a number of ways to do that. I described some of them earlier, but I'll add a few more here. For the benefit of others researching this topic, disabling the fuel pump you mentioned is a valid way to do this, but there's two problems here. Mainly, the fuel pump relay is not removable. It's soldered to the circuit board inside the fuse box, so if it fails, the entire fuse box must be replaced. Second, for engines that were run recently, the fuel pressure remains in the line to the engine for weeks or months. That pressure can be enough to allow an engine to run for a good four or five seconds. By the time the engine stalls, the oiling system has been up to pressure already, so nothing has been gained.

I mentioned unplugging all of the injectors. The drawback there is the lack of current flow will be detected, and multiple diagnostic fault codes will set. Until those codes are erased, they can prevent some other codes from setting or even having tests run that could detect a problem. I don't recommend unplugging ignition coils. That will allow a buildup of raw fuel in the cylinders.

My preferred method is to crank the engine with the ignition switch not even turned on. No fuel flow, no injector pulses, and no chance of setting a fault code that could potentially confuse some other issue later. One way to run the starter motor is to go right to it, then use a screwdriver to connect the two wires right on the starter solenoid. The fat one comes right from the battery positive post. The smaller one gets 12 volts from the starter relay. You're providing that 12 volts by connecting those two wires. This works best when the truck is already up on a hoist, and it's easier to reach the starter. Some starter designs don't lend themselves to doing this. The larger terminal can have a hard plastic shield to protect it.

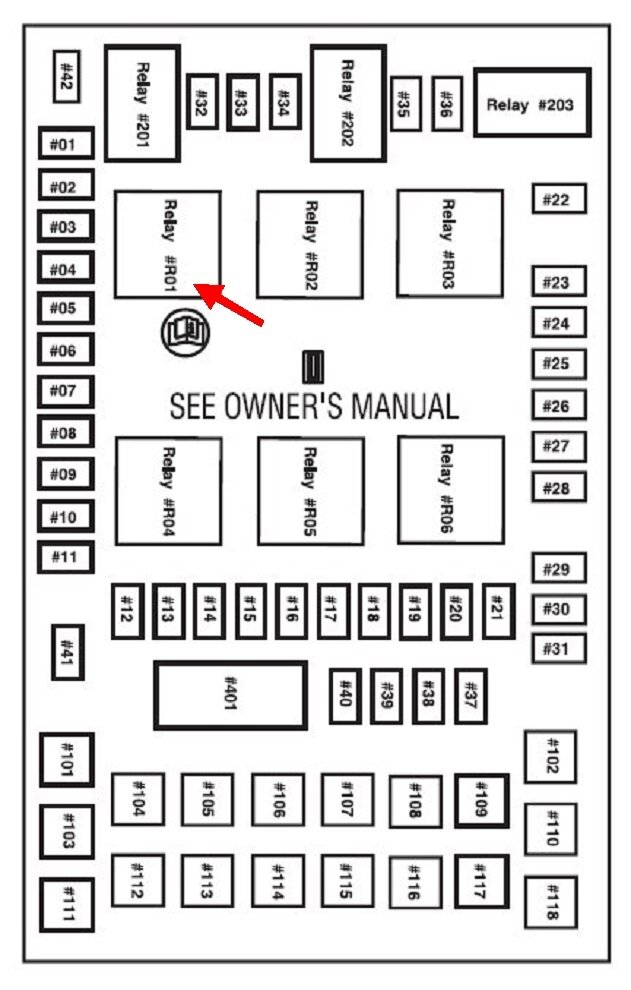

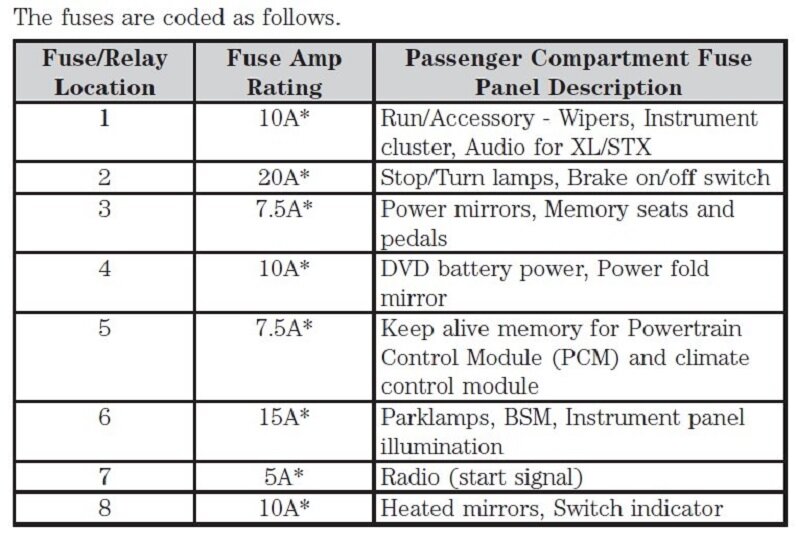

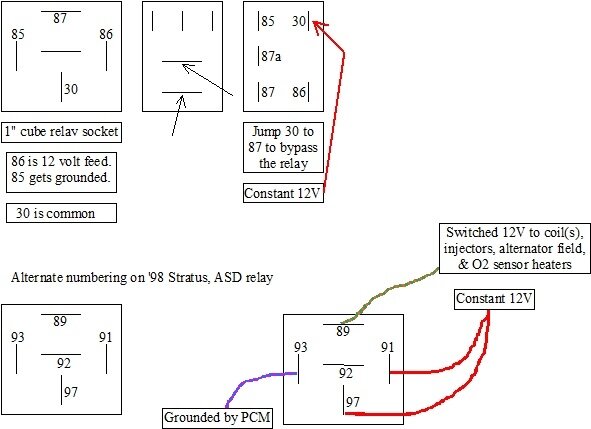

By far the easiest way to do this is what I mentioned previously. Just turn on the starter relay manually, without using the ignition switch. The first drawing below shows the fuse / relay box layout. It's not particularly easy to read, so I expanded the part with the starter relay. This is the same 1" cube relay Chrysler and a lot of other manufacturers use, and here, Ford is using the same standardized numbering. I added two red arrows to show the two terminals to connect. A stretched-out paper clip works fine, or any piece of wire. Notice how terminal 87 lays flat, or left to right, and terminal 30 goes up and down. Those two lines form the letter "T". Any time you see this style relay, look for those two terminals when you want to jump, or bypass the relay.

Another way to do this, since you have the relay out now, is to pop the cover off, reinstall it that way, then squeeze the movable contact. Sometimes the cover can be hard to remove. Sometimes they pop off very easily. Most of the time, when I push them back in without the cover, I accidentally press the contact, then get surprised when not expecting the circuit to activate. If you do that, you can usually pop the cover back on while the relay is still plugged in.

You can't possibly find an easier or faster way to crank the engine without it starting. Be aware though, the truck has been sitting for a year, and I don't know if there is a related history for that, but under normal conditions, the fuel pump will only run for one or two seconds when the ignition switch is turned on. It won't resume running until the engine is rotating, (cranking or running). There is going to be no fuel pressure now, (unless you've been turning the ignition switch on recently), and when you do try to start the engine, the starter will naturally draw the battery's voltage down quite a bit. That means the fuel pump will run much slower than normal. It can take a little time to build fuel pressure high enough for the engine to run.

You can also disconnect a couple of sensors to create a crank / no-start condition, but that would be the most difficult way to do it. You'd have to turn the ignition switch on, and the Engine Computer would instantly detect the missing signals and set related fault codes. Just getting to some of those sensors can be time-consuming and frustrating.

Let me know if you still are confused or have other questions.

Images (Click to make bigger)

SPONSORED LINKS

Monday, April 1st, 2024 AT 4:12 PM