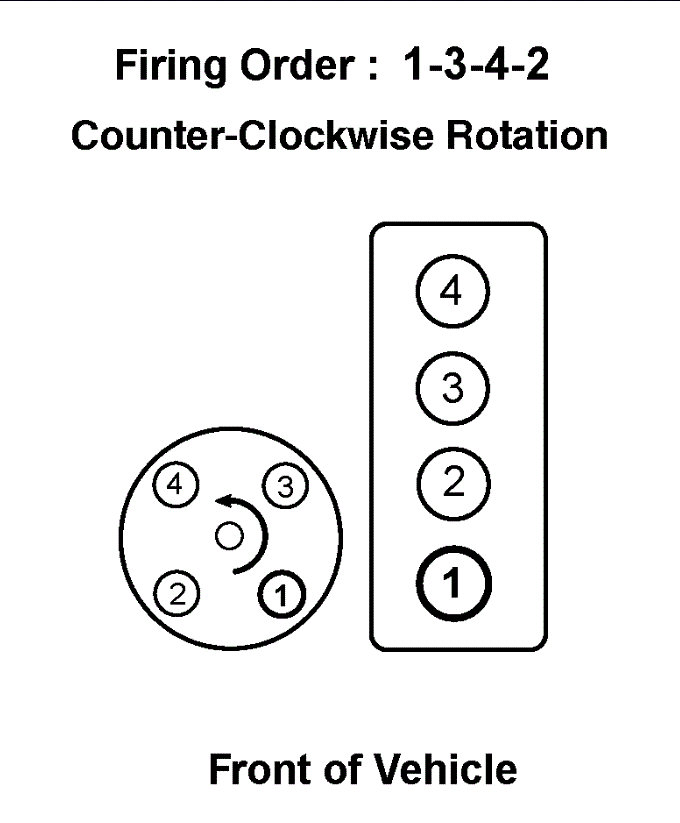

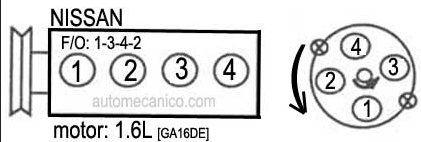

Yeah, I was thinking about why rotating it 360 degrees would have any effect, but then I was thinking that the Distro head has to rotate 16 times (twice for each piston) before a signal is sent at the exact moment it is pointing to the #1 cylinder. It appears that I got lucky and did not have to do it 15 times. However, the timing marks are still off. One of my mechanic friends found something that I tried.

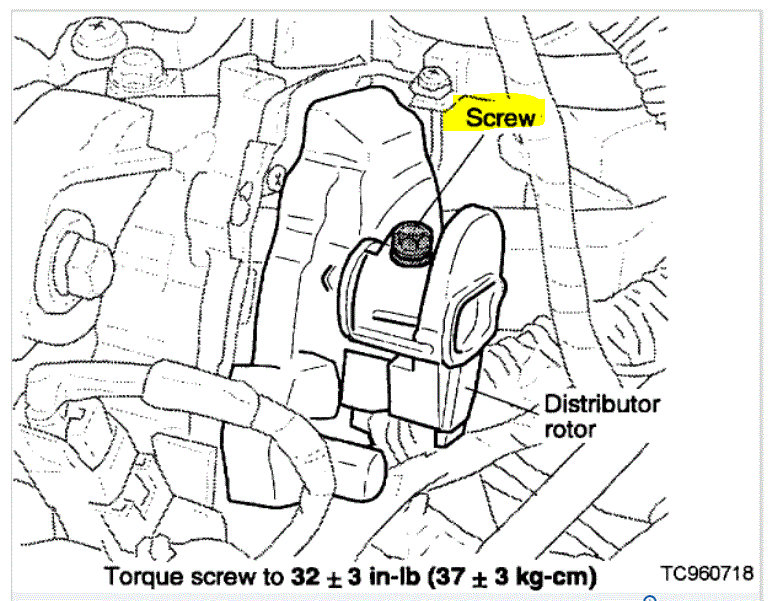

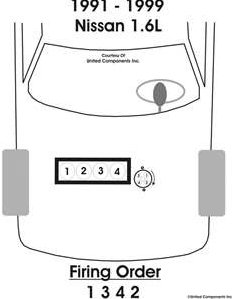

It appears that in the 1990's some manufacturers would require you to disconnect some wire to properly set the timing. We found a YouTube video for this engine that says. 1) run engine up to normal operating temperature, 2) shut off engine and disconnect the Throttle Position Sensor wiring clip, 3) restart engine and increase RPM to 2,000 2 to 3 times, 4) check timing and rotate distributor until 8-10 BTC is achieved.

I re-read the Distributor Replacement and Timing Setting instructions in my Haynes manual and it says nothing about that at all. Anyway, I tried, and it works perfectly and the timing are right at 8-10 BTC.

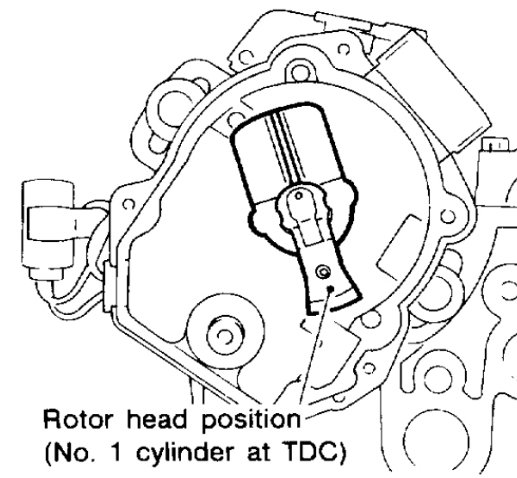

I still don't know why rotating the distro 360 degree had any effect, but there must be some mechanical portion of the distro that needs to be aligned for #1 cylinder, like a complex clock work? I guess?

Monday, May 2nd, 2022 AT 7:04 PM