Hey Mike.

No that is not my car ..I just put it there to fly the flag so to speak .... my car is better .. LOL .. And yes I'm English but I live in the USA ... I need to go back over some of your recent post's to check where we are upto ... in the meantime do these check's ... I'm thinkin at the minute the ECM may be faulty ... speak later ...

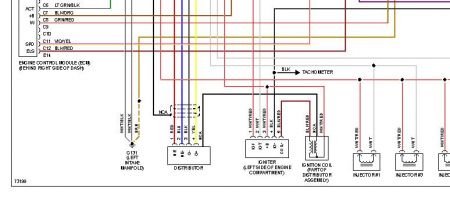

Check ignition IGT signal from Engine Control Module (ECM). If ignition IGT signal from ECM is defective a diagnostic trouble code will be set in the ECM memory to indicate a ignitor circuit malfunction. See the TESTS W/CODES article for diagnostic trouble code. If IGT signal is okay, substitute another ignitor and recheck system operation.

The ECM uses pick-up coil input signals to switch primary ignition circuit on and off. Primary circuit is turned off when ECM delivers a signal to igniter on the IGT wire, causing ignition coil to fire spark plug. After delivering a command to turn off primary circuit on IGT wire, the ECM monitors IGF circuit to ensure primary switching occurred. Code is set when no IGF signal to ECM for 4 consecutive IGT signals during engine operation. Possible causes are:

IGF or IGT open or short circuit.

Igniter.

ECM.

Diagnosis & Repair

Inspect for spark at plugs. Remove wire from individual spark plug. Remove spark plug and insert into wire. Disconnect appropriate injector harness connector. Ground spark plug and crank engine. Ensure spark is present.

If spark does not exist, go to step 5). If spark does exist, inspect IGF circuit between distributor and ECM for short or open. See wiring diagram in the WIRING DIAGRAMS - 2.2L article.

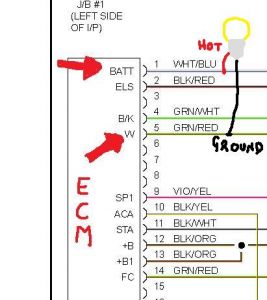

Repair as needed. If circuit is okay, disconnect igniter connector. Igniter is behind air cleaner housing. Access ECM behind glove box. Turn ignition on. Using DVOM, backprobe ECM connector.

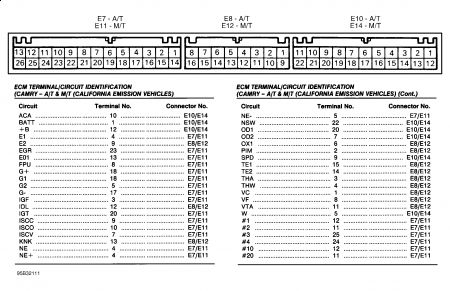

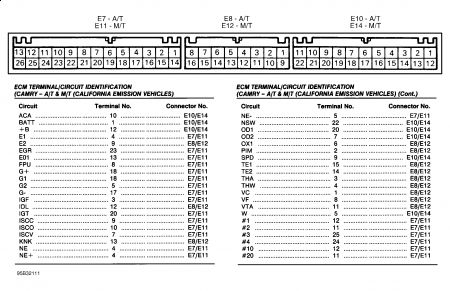

Measure voltage between terminal IGF and ground. See Fig. 5 (M/T Except Calif.) or 6 (A/T & M/T Calif.). If voltage is 4.5-5.5 volts, replace igniter and retest. If voltage is NOT 4.5-5.5 volts, replace ECM and retest.

Access ECM behind glove box. Turn ignition on. Using DVOM, backprobe ECM connector. Measure voltage between terminal IGT of ECM connector and ground, while cranking engine. Voltage should be .5-1.0 volt.

If voltage is within specification, go to next step. If voltage is NOT within specification, go to step 11).

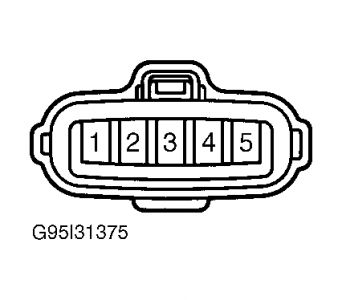

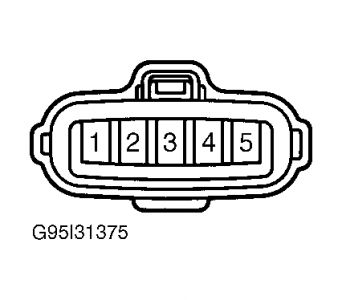

Disconnect igniter connector. Igniter is located behind air cleaner housing. Measure voltage between harness connector terminal No. 3 and ground. See Fig. 7 . Turn ignition switch to ON posit ion. Voltage should be 9-14 volts. Turn ignition switch to START position. Voltage should be 9-14 volts.

If voltage is NOT within specification, inspect igniter power supply circuit. See wiring diagram in WIRING DIAGRAMS - 2.2L article. Repair as needed.

If voltage is within specification, inspect circuit between ignition switch and ignition coil, ignition coil and igniter for open or short. See wiring diagram in WIRING DIAGRAMS - 2.2L article. Repair as needed. If circuit is okay, go to next step.

Inspect ignition coil. See the BASIC TESTING - 2.2L article. Replace ignition coil as needed. If ignition coil is okay, replace igniter and retest.

Access ECM behind glove box. Turn ignition on. Using DVOM, backprobe ECM connector. Ensure igniter connector is disconnected. Measure voltage between terminal IGT of ECM connector and ground, while cranking engine. See Fig. 5 (M/T Except Calif.) or Fig. 6 (A/T & M/T Calif.). Voltage should be .5-1.0 volt.

If voltage is within specification, replace igniter and retest. If voltage is NOT within specification, inspect IGT circuit between igniter and ECM for open or short. Repair as needed. If circuit is okay, replace ECM and retest.

Fig. 6: Identifying ECM Connector Terminals (A/T & M/T Calif.)

Fig. 7: Identifying Igniter Harness Connector Terminals

Sunday, April 26th, 2009 AT 6:01 AM