You have to specify the engine size when you have this type of problem. The 3.0L V-6 was an upgrade optional engine that has extremely little trouble with the ignition system. Almost all crank / no-starts are caused by a loss of spark, injector pulses, and fuel pump. The misleading clue is the fuel pump will still run for one second when you turn on the ignition switch and you may hear the hum at that time. That is to insure fuel pressure is up for starting in case it bled down over days or weeks. Since the injectors don't fire with this common failure, no fuel is used up from the supply system, so fuel pressure doesn't drop. That falsely removes the fuel pump from the list of symptoms or observations.

The same can be said of the 2.5L 4-cylinder engine, but this failure is a lot more common with an easy repair. We normally never approve of throwing random parts at a problem as a means of diagnosis, since that is the most expensive and least effective way to solve a problem. One exception, however, is the pick-up assembly inside the distributor. They have such a high failure rate, a lot of owners carry a spare in the glove box. To add to the confusion, as with their counterparts on all newer engines of all car brands, these often fail by becoming heat-sensitive, then they work again after cooling down for about an hour.

When this pick-up assembly fails, it stops sending signal pulses to the Engine Computer. Those pulses are what tells the computer the engine is rotating, (cranking or running), and it's time to turn on the automatic shutdown, (ASD) relay. That relay sends current to the ignition coil, injector(s), alternator field, and fuel pump or separate fuel pump relay. The common mistake too many people make is they try to repair the circuit for the first thing they find missing, rather than looking for other things the failure has in common. Most of the time they find the loss of spark and concentrate on that. In fact, loss of spark only accounts for about two percent of these crank / no-starts, and a dead fuel pump accounts for about three percent. A good 95 percent are caused by the distributor pick-up assembly. Chrysler calls this the "Hall Effect Switch" for the type of switching transistor it uses. You may also find it called the "ignition pick-up coil", "distributor reference sensor", or camshaft position sensor".

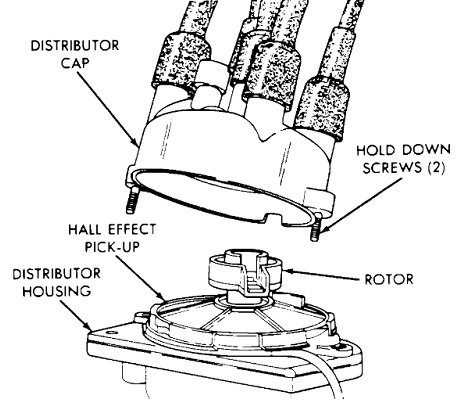

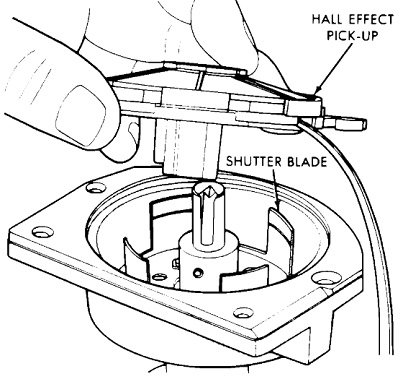

This photo shows what it looks like. Remove the two screws that hold on the tall black plastic water shield in front of the distributor, then unbolt the distributor cap. Lift off the ignition rotor, then lift up the pick-up assembly. Install the new one in the reverse order.

Also be aware the same problem will occur if the timing belt breaks. Unlike with a pick-up assembly that is often intermittent, a broken or jumped timing belt is never intermittent. Those failures are permanent. The clue to a timing belt problem is the engine will not sound normal during cranking. It will spin faster and smoother than normal. The glaring clue to a broken timing belt is the ignition rotor will not rotate during cranking. The 2.2 / 2.5L engines are not of the interference design, so no valves will be damaged if the timing belt breaks. Belt replacement is not very difficult, but it does require a special weighted tool to set the tension on the new belt.

Images (Click to make bigger)

SPONSORED LINKS

Friday, July 24th, 2020 AT 6:13 PM

(Merged)