Hi and thanks for using 2CarPros.com.

For some reason, the Lancer is not listed in any of my manuals. However, I believe in 1993, the Mirage was based on the same platform. With that in mind, the fuel pump is electric and is located in the fuel tank. Here is a test you can do to check if it is working:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Here are the directions specific to a 1993 Mitsubishi Mirage. I believe it is the same. The attached pictures correlate with these directions.

_______________________________________________________________

OPERATIONAL CHECK (QUICK CHECK):

1. Turn the ignition switch OFF

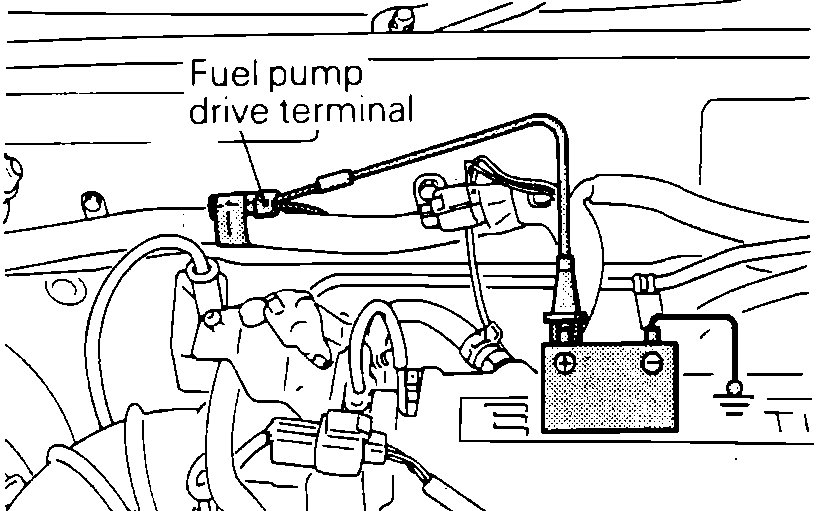

Fuel Pump Power Hook-up

imageZoom/Print

2. Apply battery voltage to the fuel pump drive connector to power the fuel pump.

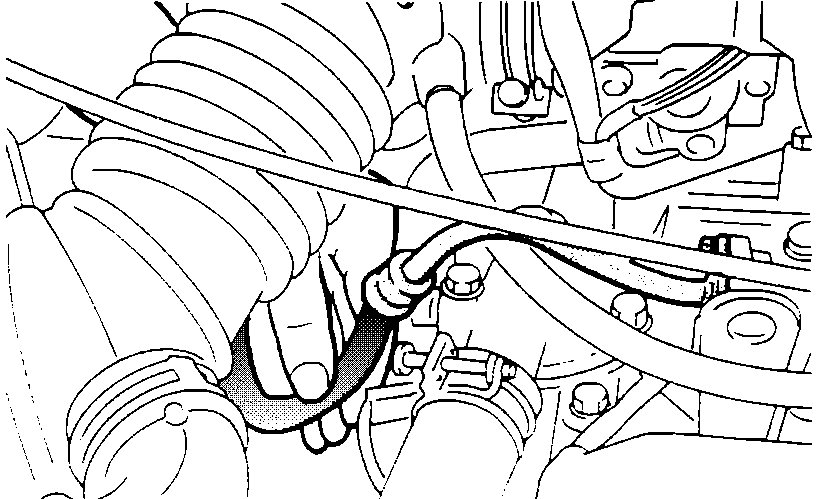

Fuel Pump Operational Test

imageZoom/Print

3. Pinch the fuel hose to check that fuel pressure is felt.

NOTE: The fuel pump is mounted in the fuel tank and it operates submerged in fuel, therefore its operating sound is hard to hear without removing the fuel filler cap.

PRESSURE TEST (DIAGNOSTIC CHECK):

1. Reduce the internal pressure of the pipes and hoses by the following procedures.

a. Disconnect the fuel pump harness at the rear of the fuel tank.

b. Start and run the engine until it stalls. Turn OFF the ignition key.

c. Disconnect the battery negative terminal.

d. Connect the fuel pump harness connector.

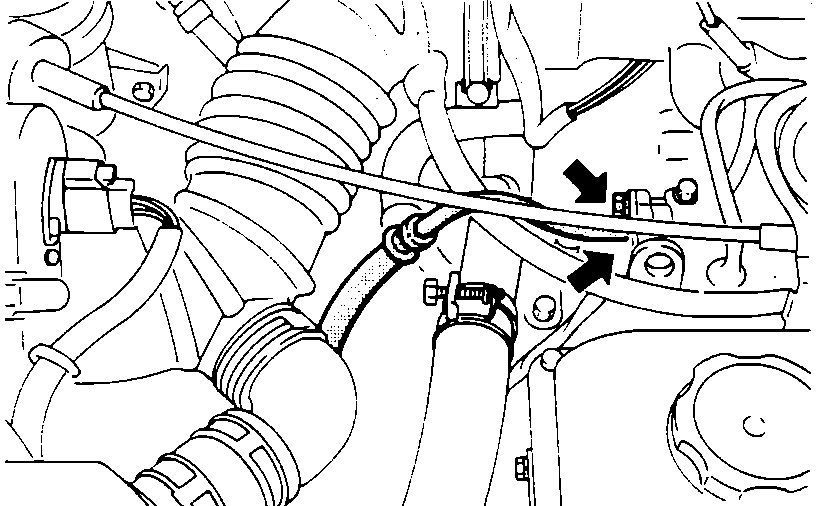

High Pressure Fuel Hose Connection

2. Disconnect the high pressure fuel hose at the delivery end.

CAUTION: Cover the hose connector with a shop towel to prevent splashing of fuel caused by residual pressure in the fuel line.

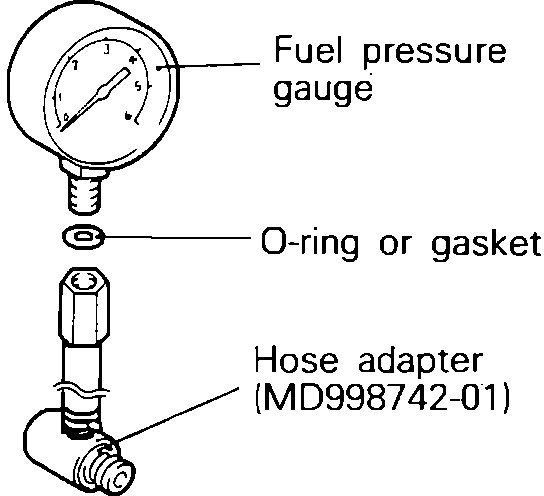

Fuel Pressure Testing Equipment And Adapter

imageZoom/Print

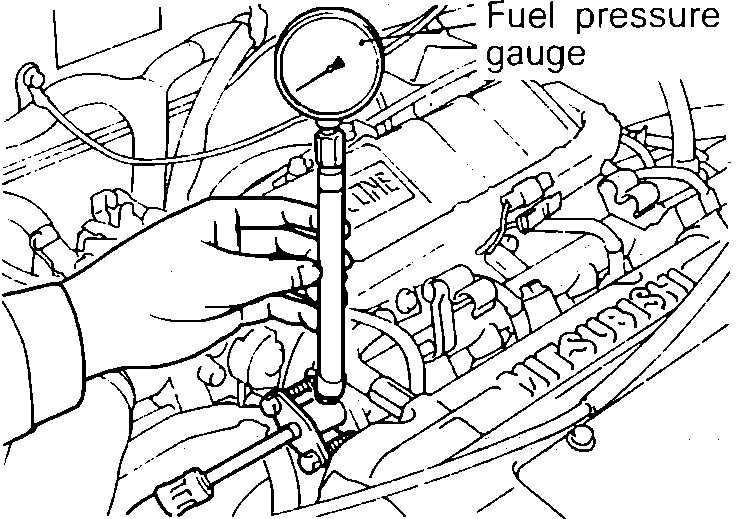

Fuel Pump Pressure Test Equipment Installed

imageZoom/Print

3. Using the fuel pressure gauge adapter (MD998742-01) or equivalent, install the fuel-pressure gauge to the delivery pipe (fuel rail).

4. Connect the battery negative terminal.

5. Apply battery power to the fuel pump drive terminal to activate the fuel pump. With fuel pressure applied check that no fuel is leaking at any of the connections.

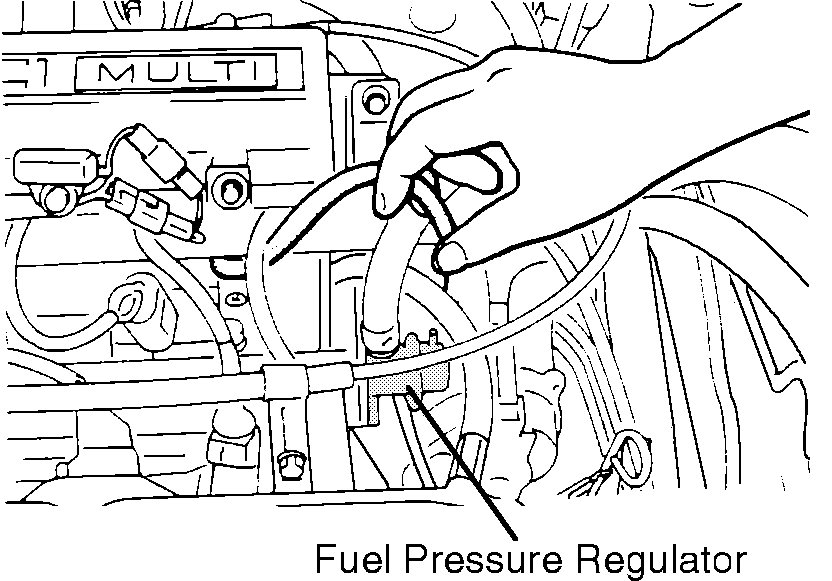

Fuel Pressure Regulator W/Vacuum Line Disconnected

imageZoom/Print

6. Disconnect the vacuum hose from the pressure regulator, and plug the hose end. Measure the fuel pressure at idle.

Standard Value:

47 - 50 psi (330 - 350 kPa)

7. Measure the fuel pressure when the vacuum hose is connected to the pressure regulator.

Standard Value:

38 psi (270 kPa).

NOTE: At the completion of steps 5 thru 7, prior to turning the ignition off, disconnect the battery power to the fuel pump drive terminal. If the engine stops and NO fuel pressure is observed, refer to COMPUTERIZED ENGINE CONTROLS to diagnose the fuel pump power supply problem.

8. If the results of the measurements made in steps 6 and 7 are not within the standard values, refer to the symptoms listed below to determine the probable cause and make the necessary repairs before re-testing.

a. Fuel pressure too low:

1. Clogged fuel filter---Replace

2. Fuel bleeds down to return hose---Replace the fuel pressure regulator

3. Low pump output pressure---Check for leak in-line or replace fuel pump

b. Fuel pressure too high:

1. Regulator stuck closed---Replace the fuel pressure regulator

2. Clogged or bent fuel return hose---repair hose

c. No difference with or without vacuum connected:

1. Non-responsive regulator---Replace the fuel pressure regulator

2. Plugged vacuum line or no source vacuum---replace line or repair vacuum source

9. Stop the engine and check for a change in fuel pressure readings. Pressure should hold for 5 minutes. If the gauge reading drops, observe the rate of drop. Determine the cause according to the following symptoms.

a. Fuel pressure drops slowly:

1. Injector leakage---Identify leaking injector and replace.

2. Regulator is leaking to return line---Confirm and replace regulator.

3. Check valve in the fuel pump is leaking---Replace the pump.

b. Fuel pressure drops immediately:

1. Regulator is leaking to return line---Confirm and replace regulator.

2. Check valve in the fuel pump is open---Replace the pump.

10. At the completion of testing, remove the test equipment and reconnect the high pressure fuel hose to the fuel rail.

Torque value:

3 - 4 ft.lbs. (4 - 6 Nm)

__________________________________________

I hope you find this information helpful. Let me know if you have other questions or need additional information.

Take care,

Joe

Images (Click to make bigger)

Wednesday, March 31st, 2021 AT 12:32 PM