NOTE:For trouble shooting charging system, see BASIC TROUBLE SHOOTING article in GENERAL INFORMATION.

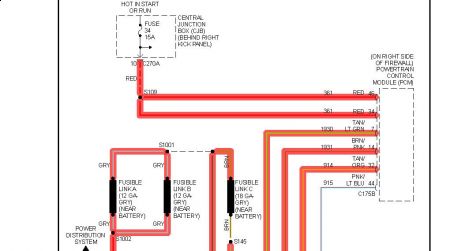

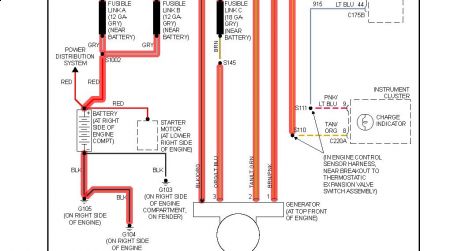

Ensure connections at generator, regulator and engine ground are clean and tight. Ensure battery posts and cables are clean and tight. Inspect drive belt. Inspect central junction box fuse No. 9 (10-amp) and fuse No. 34 (20-amp). Inspect fusible links. Check all connections for looseness or corrosion. If problem is found, repair as necessary. If problem is not found, see SYSTEM TESTS.

BATTERY DRAIN TEST

Ensure junction box/fuse panels are accessible without turning on interior and hood lights. Drive vehicle over 30 MPH for at least 5 minutes. Park vehicle and allow to sit with ignition off for at least 40 minutes to allow electronic modules to power down. Go to next step.

Connect a fused jumper wire between negative battery cable and negative battery post. Disconnect negative battery cable from negative battery post, without breaking the jumper wire connection to prevent modules from resetting. Go to next step.

NOTE:It is very important that continuity is not broken between negative battery post and negative battery cable when disconnecting battery cable or connecting ammeter. If continuity is broken, go to step 1.

Ensure ammeter is set to read milliamps with at least a 10-amp capability. Connect ammeter between negative battery cable and negative battery post. Remove fused jumper wire. Go to next step.

Note amperage draw. Draw will vary from vehicle to vehicle depending on the equipment package. Compare to a similar vehicle for reference. No factory equipped vehicle should have more than a 24-26 mA draw (0.024-0.026 amp).

If excessive current draw is present, pull fuses from battery/central junction box one at a time and note any current drop when each fuse is removed. DO NOT reinstall fuses until test is complete. Go to next step.

Check wiring diagrams for any circuits that run from battery without passing through battery/central junction box. Disconnect these circuits if current draw still exists.

GENERATOR LOAD TEST

Ensure drive belt is in good condition. Replace belt as necessary. If belt is okay, connect charging system load tester in accordance with manufacturer's instructions. Start and run engine at 2000 RPM, and apply load until generator output levels off. Generator amperage should be at least 75 amps, with engine at 2000 RPM.

If voltage is as specified, system is operating properly at this time. If voltage is not as specified, see SYMPTOM INDEX table under SYSTEM TESTS.

GENERATOR NO-LOAD TEST

Switch tester to voltmeter function. Connect voltmeter positive lead to B+ terminal on generator and negative lead to ground. Turn all electrical accessories off. Start and run engine up to 2000 RPM. Read voltmeter when voltage stabilizes. Voltage should be 13-15 volts.

Turn A/C system on. Turn blower speed to high. Turn headlights on to high beams. Voltage should increase a minimum of.5 volt. If voltage is not as specified, go to SYMPTOM INDEX table under SYSTEM TESTS. If voltage is as specified, charging system is operating normally.

SPONSORED LINKS

Was this helpful?

Yes

No

+3

Friday, November 2nd, 2018 AT 11:53 AM

(Merged)