Integrated Electronic Ignition (EI) system consists of a crankshaft position sensor, coil pack(s), wiring, and PCM. Coil On Plug (COP) integrated EI system uses a separate coil for each spark plug and each coil is mounted directly onto spark plug. COP integrated EI system eliminates need for spark plug wires but does require input from camshaft position sensor.

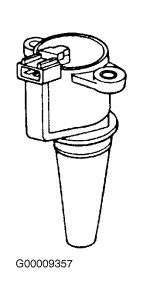

Coil On Plug

The Coil On Plug (COP) ignition operates similar to a standard coil pack ignition except each spark plug has one coil per spark plug. See Fig. 8 . COP has 3 different modes of operation:

Engine Cranking

During engine cranking, Powertrain Control Module (PCM) will fire 2 spark plugs simultaneously. One spark plug will fire on the compression stroke and the other spark plug fires on the exhaust stroke. Both spark plugs will fire until camshaft position is identified by a successful camshaft sensor signal.

Engine Running

Once camshaft position is identified and engine is running, only spark plug on compression stroke will be fired.

CMP Failure Mode Effects Management (CMP FMEM)

During CMP FMEM, COP ignition operates similar to engine cranking mode. This allows engine to operate without requiring PCM to know if cylinder is on compression or exhaust stroke.

Fig. 8: View Of Coil On Plug - Typical

A coil in a coil pack is turned on (coil charging) by powertrain control module, and is turned off when 2 spark plugs are fired simultaneously. Spark plugs are paired so that one spark plug fires on the compression stroke and other spark plug fires on exhaust stroke. Next time coil is fired, order is reversed and next pair of spark plugs fire according to engine firing order.

A 3-pin Hall Effect type sensor or a 2-pin variable reluctance Camshaft Position (CMP) sensor is used. CMP sensor is used to determine camshaft position and to identify when piston No. 1 is at Top Dead Center (TDC) of compression stroke. CMP sensor signal is used by Powertrain Control Module (PCM) for synchronizing firing of sequential fuel injectors. Applications with Coil On Plug (COP) ignition also use CMP signal to select the proper ignition coil to fire.

Crankshaft Position Sensor

The Crankshaft Position (CKP) sensor is a magnetic transducer mounted on engine block, next to crankshaft pulse wheel. On all engines except 6.8L, trigger wheel has a total of 35 teeth spaced 10 degrees apart with one empty space for a missing tooth. On 6.8L trigger wheel has a total of 39 teeth spaced 9 degrees apart and one 9 degree empty space for a missing tooth. By monitoring pulse wheel, the CKP sensor indicates crankshaft position and speed information to Powertrain Control Module (PCM). By monitoring missing tooth, CKP sensor is also able to identify piston travel to synchronize ignition system and provide a way of tracking angular position of crankshaft relative to a fixed reference.

Wednesday, August 12th, 2020 AT 1:46 PM

(Merged)