This system has been around for over thirty years, and all other manufacturers use some variation of it. Your observation of no spark is a dandy clue, but you must check the voltages you listed while cranking the engine, otherwise they had better not be there.

The place to start is by reading the diagnostic fault codes. Chrysler made doing that yourself much easier than any other manufacturer. Cycle the ignition switch from "off" to "run" three times within five seconds without cranking the engine, leave it in "run", then watch the code numbers show up in the odometer display. You can go to this page:

https://www.2carpros.com/trouble_codes/obd2/p0300

to see the definitions, or I can interpret them for you. Do not panic if there are no codes related to this problem. The two most common causes often do not set codes just from cranking the engine. They usually need more time to set, as in when a stalled engine is coasting to a stop.

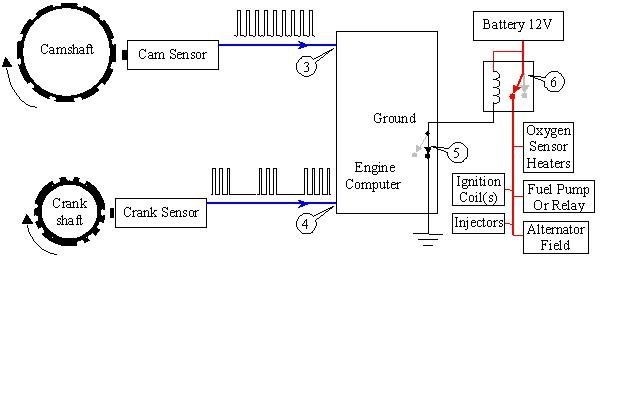

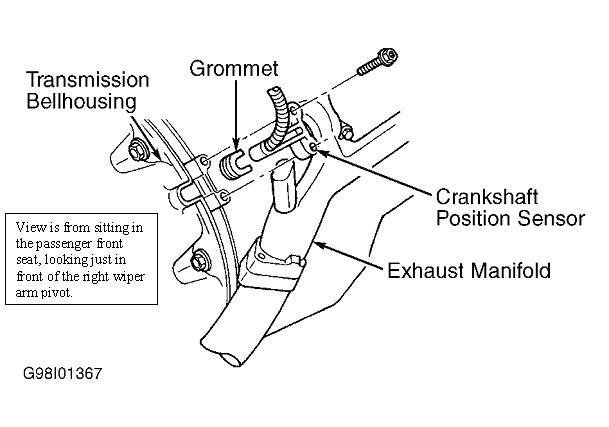

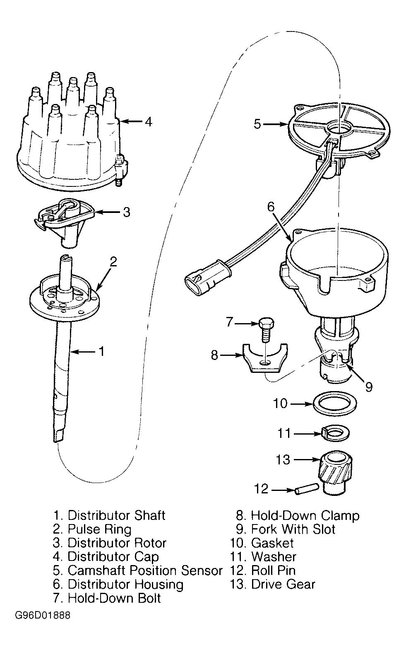

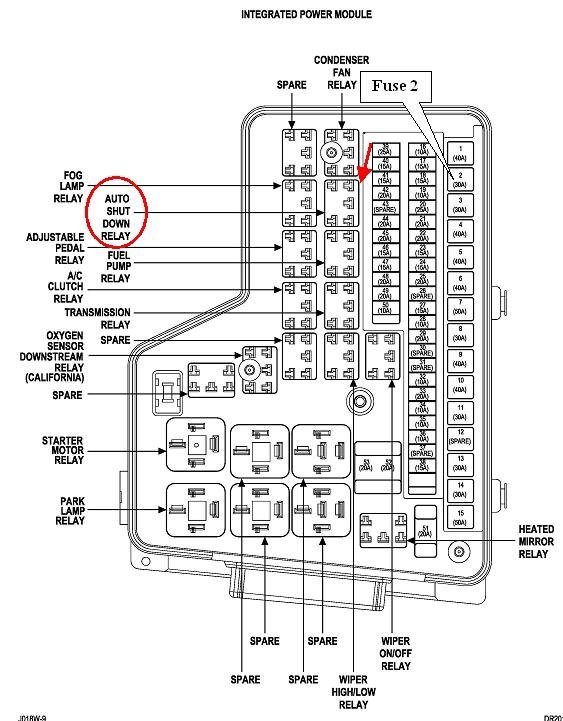

First let me describe how this system works. When you turn on the ignition switch, the Engine Computer turns on the automatic shutdown, (ASD) relay for one second. You might hear the hum of the fuel pump during that time. When you start cranking the engine, the computer receives signal pulses from the crankshaft position sensor behind the rear of the right cylinder head, and the camshaft position sensor. That is a disc under the rotor in the distributor. The signals from the two sensors tell the computer the engine is rotating, (cranking or running), so it turns the ASD relay on again. That is the step that most commonly does not occur, due to a failed sensor.

The ASD relay sends current to the ignition coil, injectors, oxygen sensor heaters, alternator field, and fuel pump or pump relay. The purpose of this safety system is in the event of a crash in which a fuel line gets ruptured, the pump would dump raw gas on the ground creating a serious fire hazard. With a broken fuel line there cannot be any fuel pressure. Without pressure, no fuel can spray from the injectors, so the engine stalls. Once stalled, the signal pulses stop arriving from the two sensors, so the computer turns the ASD relay off. That stops the fuel pump.

If you have access to a scanner, use it to view live data and look at how the two sensors are listed. I have a Chrysler DRB3 for all of my vehicles. That lists the sensors with a "No" or "Present" during cranking. Aftermarket scanners should have a similar way of showing this. If you find one that stays on "No" during cranking, or if you find a diagnostic fault code related to one of them, that only indicates the circuit that needs further diagnosis. There is only about a fifty percent chance the problem is actually caused by the sensor listed in the code. You first must look at wiring and connector terminals, and for mechanical problems related to that sensor. For example, on older models, the critical air gap for the crankshaft position sensor was set accurately with a glued-on paper spacer. If that is not used, you can run into an intermittent stalling problem, (do not ask me how I learned that!), a crank/no-start, or the sensor can hit the flex plate and break. That sensor in 2002 uses a different-style bracket that prevents the air gap from being set incorrectly, so that is one thing we do not have to worry about.

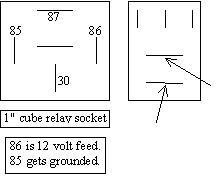

When you do not have a scanner, the fastest way to determine if the ASD relay is being turned on is to measure the voltage at the ignition coil, any injector, or either smaller wire on the back of the alternator. That wire at all those places is always the same color; dark green/orange. A test light works best for this because you can see it from inside the truck, and digital voltmeters usually do not respond fast enough. You should see the test light turn on full brightness for one second when you turn on the ignition switch. What is important is if it turns on again during cranking. If it does, you have a failed fuel pump or a failed ignition system, but not both. These two symptoms account for only about five percent of crank/no-starts.

When the light does not turn on again during cranking, you will have a failed fuel pump, no spark, and no injector pulses. This accounts for the other ninety five percent of crank/no-starts. Most commonly it is caused by the cam or crank sensor, but as I mentioned, we do not want to just throw a new sensor at it without checking the wiring first. Either of these sensors on any brand of car or truck often fail by becoming heat-sensitive, then they work again after cooling off for about an hour.

This first diagram is a representation I drew up to show what is involved with this circuit. The second one shows the location of the crankshaft position sensor, and the third one shows what is involved in replacing the camshaft position sensor.

Images (Click to make bigger)

Saturday, September 29th, 2018 AT 5:43 PM