A lot of auto parts stores rent or borrow tools, so that would be a good place to start. The problem is the stores in my city make you buy the tool, then they give you a full refund when you bring it back. If you decide to keep it, you return theirs, then they give you a new one. It still doesn't hurt to ask.

Check at some local pawn shops too. To get a good deal, you have to look for those in online auctions, like eBay and Ebid. I've found items in their stores are priced almost as high as a new version. You can negotiate in the stores, but it's still uncommon to come away with a good deal. Look for a Solus Edge that is far out-of-date. As I mentioned, to bring one up to the latest updates to work on 2019 models, you'd have to buy every single year that is missing, and that can easily cost a real lot more than buying a new scanner that comes with the latest software. Also, these come with U.S. Domestic, Asian, and European software packages that you select individually. If you can find one in a pawn shop that doesn't have the European package, pretend that's what you really need, as a bargaining chip. They'd rather have your cash than a scanner sitting on the shelf, so they should be willing to deal. They know about the real high cost of updates. They're hoping someone buys it who is not aware of that. In your case, we don't care how far out-of-date it is as long as it works on a '98 model. More commonly you're going to find these for less than $1000.00 updated through 2014 to 2016.

Ask around at some local repair shops, and even at the Chrysler dealership, to see if they have a DRB3 they are willing to borrow. I just dug mine out last Saturday for the first time in about a year, and I solved a whole string of issues going back to the previous owner, on my '94 Grand Voyager. I solved intermittent failure to up-shift, intermittent slightly high idle speed, and an intermittent crank / no-start, by just watching the signal voltage from the throttle position sensor. Never would have figured that out without a scanner.

When I worked at the dealership, the owners were real good about helping out regular customers by borrowing out special tools and service manuals. The service advisors also were allowed to send service manuals or photocopies to other dealers in the area. We repaired each others' trade-ins at times too, so we had real good relationships with customers and with all the other dealerships except the Chevy dealer. There were times I was asked to hunt down one of our shelved DRB2s to borrow to a customer, once the DRB3 came out. If I wasn't real busy with a customer's car, I was allowed to show the person how to use the scanner and what to look for. The dealership owners' thinking was teaching a customer how to diagnose their own car was not going to put us out-of-business. It was only going to make them like us that much more.

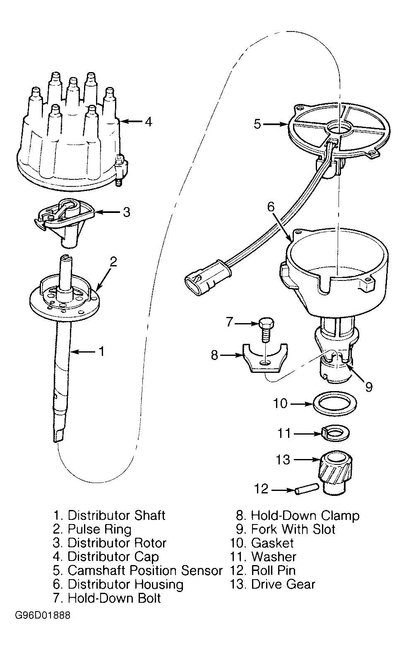

Not having access to a scanner is like a doctor not having a stethoscope. There's just so much you can do before you have to call someone else. I can offer a few comments of value related to the two sensors. The distributor pick-up assembly, (camshaft position sensor), is a "Hall Effect" sensor, the same type of disc that was used on the 2.2 / 2.5L engines. Those had a very high failure rate. That would be a real good suspect if you put in a used one previously, but they usually were not intermittent. Once they failed, they failed.

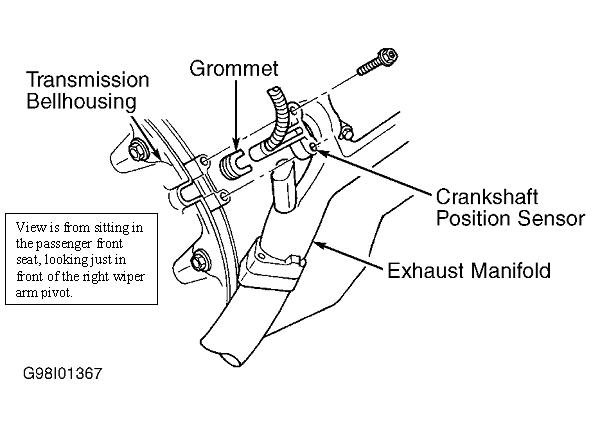

The crankshaft position sensor for your engine is an improved design over the original ones. The first ones needed to be installed with a special paper spacer to set the critical air gap. Yours has a redesigned mounting bracket that makes it impossible to set wrong. There have been some stories about the magnet core cracking, causing a popping or back-firing problem. I've never run into that myself. This sensor does have internal electronic circuitry, as evidenced by it having three wires instead of two. That circuitry lends itself to failing by becoming heat-sensitive on all car brands. A common symptom is they work fine as long as you're driving, but cause a crank / no-start right after a short stop, such as when stopping for gas. While standing still with no natural air flow, heat from the engine migrates up to the sensor, causing it to fail. We call that "hot soak". The sensor usually works again after cooling down for about an hour.

The crank sensor on your engine is somewhat hard to get to. It's in the transmission bell housing, right behind the right cylinder head. I would only replace it as a test if I already had a new one on hand. The problem with intermittent problems is when you do replace a random part, you will never know if that solved it. You will only know it did not solve it if it acts up again. I wouldn't want to drive to another state and risk it acting up again. If you can find a missing signal on a scanner, that would give you the confidence to at least know you're in the right circuit.

Images (Click to make bigger)

Monday, March 18th, 2019 AT 5:36 PM