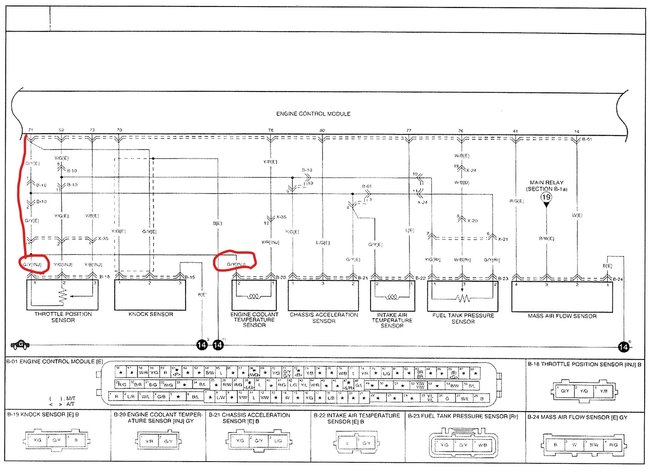

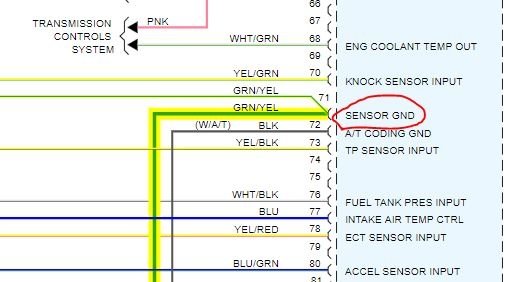

I replaced the thermostat, coolant temperature sensor, and gasket. I've replaced the coolant temperature sensor twice thinking that maybe it was a defective new part from AutoZone. I recently bought a new connector and spliced it on and still got the same results of a no start when connected. I also get the code p0117 now.

I've had my timing rechecked by a licensed mechanic thinking that may be the issue. Everything checked out fine there. I replaced the fuel pump prior to the timing belt being replaced also. It starts fine without that sensor being connected so I assume this wouldn't be the cause of the issue.

So can anyone think of any reason as to why the connector keeps the SUV from starting when it is connected? It starts up fine without the coolant temperature sensor being connected. Any help is greatly appreciated! Thank you

Wednesday, June 26th, 2019 AT 3:43 PM