This is a 2.5 L and there are various test to diagnose the problem and a scan tool is needed for most of the tests.

We shall start with Diagnostic Trouble Codes retrieval.

Perform the above test and see if any DTCs are found.

Are you able to crank the engine?

Since sparks are not available and if engine can crank, try the following.

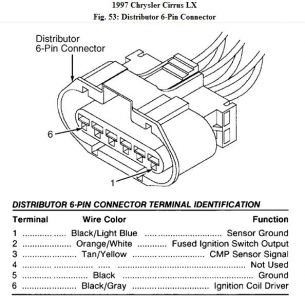

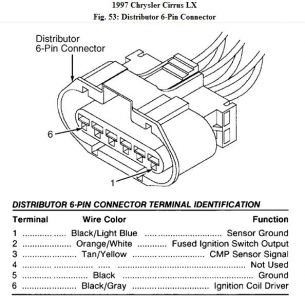

1. Turn ignition off. Disconnect distributor 6-pin connector. Using scan tool in ohmmeter mode, check resistance of ground circuit Black wire (not sensor ground circuit) at distributor 6-pin connector.

If resistance is less than 5 ohms, go to next step. If resistance is 5 ohms or more, repair open ground circuit.

NOTE: Next step checks PCM's ability to drive ignition coil driver circuit. An analog voltmeter capable of detecting 0.1 volt is necessary to perform test step.

2. Turn ignition on. Connect an analog voltmeter between ignition coil driver circuit and ground circuit at distributor 6-pin connector. Using scan tool, actuate ignition coil. If voltmeter shows a pulsating deflection, go to next step. If voltmeter does not show a pulsating deflection, go to step 4).

3. Check engine valve timing. If engine valve timing is within specification, replace ignition coil. If engine valve timing is not within specification, repair engine valve timing as necessary.

4. Turn ignition off. Disconnect Powertrain Control Module (PCM) connector. Using scan tool in ohmmeter mode, check resistance of ignition coil driver circuit Black/Gray wire at distributor 6- pin connector. If resistance is 5 ohms or more, go to next step. If resistance is less than 5 ohms, repair short to ground on ignition coil driver circuit.

5. Using external ohmmeter, check resistance of ignition coil driver circuit Black/Gray wire between distributor 6-pin connector and PCM connector terminal No. 11. If resistance is more than 5 ohms, repair open ignition coil driver circuit. If resistance is 5 ohms or less, replace PCM.

Wednesday, June 3rd, 2009 AT 12:02 PM