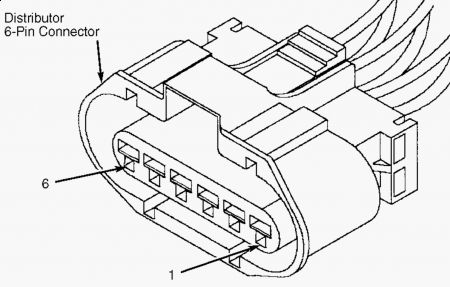

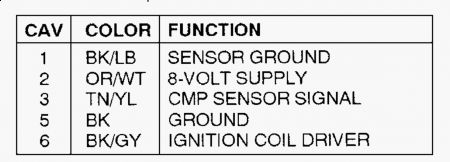

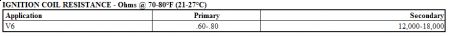

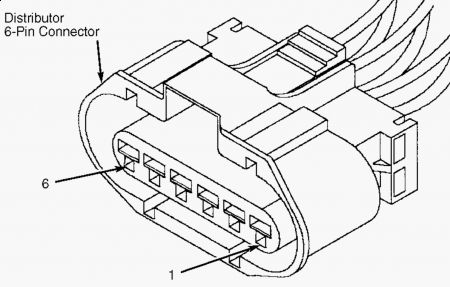

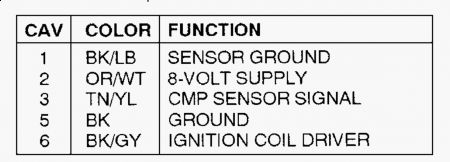

TEST NS-1A - QUALIFYING A NO START CONDITION 1. Attempt to crank engine. If engine was able to crank, go to next step. If engine was not able to crank, go to TEST NS-9A. 2. Turn ignition off, then on again. DO NOT crank engine. Using scan tool, select NO START monitor. Read current Camshaft Position (CMP) state and Crankshaft Position (CKP) state. If scan tool displays CURRENT CMP STATE PRESENT, replace CMP sensor (no signal should have been generated). Perform TEST VER-1A. If scan tool does not display CURRENT CMP STATE PRESENT, go to next step. 3. If scan tool displays CURRENT CKP STATE PRESENT, replace CKP sensor (no signal should have been generated). Perform TEST VER-1A. If scan tool does not display CURRENT CKP STATE PRESENT, go to next step. 4. While cranking engine, observe CMP and CKP state using scan tool. If scan tool shows current CKP state present, go to next step. If scan tool does not show current CKP state present, go to TEST TC-40A. 5. If scan tool shows current CMP state present, go to next step. If scan tool does not show current CMP state present, go to TEST TC-1A. 6. Go to TEST NS-1B. TEST NS-1B - QUALIFYING A NO START CONDITION 1. Disconnect cylinder No. 2 spark plug wire. Insert an insulated screwdriver in plug wire end. Hold screwdriver within 1/4" of ground. While observing for spark, crank engine for 10 seconds. Consider one or 2 sparks as a no spark condition. If good spark is present, go to TEST NS-2A. If good spark is not present, go to next step. 2. Reconnect spark plug wire. Remove distributor cap. Put one end of a spark plug wire into high tension tower of distributor. Insert an insulated screwdriver into other end of spark plug wire. Hold screwdriver within 1/4" of ground. Go to next step. 3. While observing for spark, crank engine for 10 seconds. Consider one or 2 sparks as a no spark condition. If good spark is present, replace distributor cap and rotor. Perform TEST VER-1A. If good spark is not present, go to next step. 4. Disconnect distributor 2-pin connector. Turn ignition on. Using scan tool, actuate ignition coil. Using scan tool in voltmeter mode, check voltage of ASD relay output circuit Dark NOTE: Perform all trouble code testing, that affects vehicles ability to start, before proceeding. NOTE: Steps 2) and 3) check for a stray signal. No signal should be generated. NOTE: Perform TEST NS-1A before proceeding. CAUTION: If screwdriver is more than 1/4" from ground, Powertrain Control module (PCM) damage may result. Green/Orange wire at distributor 2-pin connector. If voltage is more than 10 volts, go to next step. If voltage is 10 volts or less, repair open ASD relay output circuit. Perform TEST VER- 1A. 5. Turn ignition off. Disconnect distributor 6-pin connector. Using scan tool in ohmmeter mode, check resistance of ground circuit Black wire (not sensor ground circuit) at distributor 6-pin connector. See Fig. 50 . If resistance is less than 5 ohms, go to next step. If resistance is 5 ohms or more, repair open ground circuit. Perform TEST VER-1A. 6. Turn ignition on. Connect an analog voltmeter between ignition coil driver circuit and ground circuit at distributor 6-pin connector. See Fig. 50 . Using scan tool, actuate ignition coil. If voltmeter shows a pulsating deflection, go to next step. If voltmeter does not show a pulsating deflection, go to step 8). 7. Check engine valve timing. If engine valve timing is within specification, replace ignition coil. Perform TEST VER-1A. If engine valve timing is not within specification, repair engine valve timing as necessary. Perform TEST VER-1A. 8. Turn ignition off. Disconnect Powertrain Control Module (PCM) connector. Using scan tool in ohmmeter mode, check resistance of ignition coil driver circuit Black/Gray wire at distributor 6-pin connector. If resistance is 5 ohms or more, go to next step. If resistance is less than 5 ohms, repair short to ground on ignition coil driver circuit. Perform TEST VER-2A. 9. Using external ohmmeter, check resistance of ignition coil driver circuit Black/Gray wire between distributor 6-pin connector and PCM connector terminal No. 11. If resistance is more than 5 ohms, repair open ignition coil driver circuit. Perform TEST VER-1A. If resistance is 5 ohms or less, replace PCM. Perform TEST VER-2A. NOTE: Next step checks PCM's ability to drive ignition coil driver circuit. An analog voltmeter capable of detecting 0.1 volt is necessary to perform @test step.

12/28/2009 ...

Here's by the book on No Start for your car, but some steps require the chrysler DRB III tool!

Monday, December 28th, 2009 AT 2:58 PM