Tuesday, April 12th, 2022 AT 2:19 PM

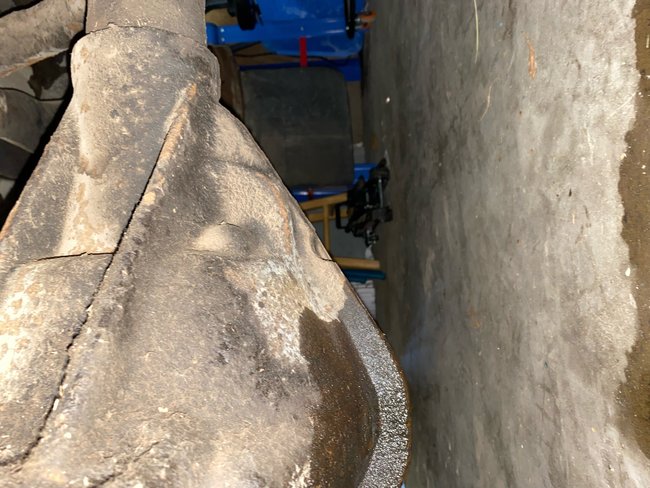

Possible bad pinion seal?

17 Replies

Unfortunately, that is what this is.

Based on this amount of oil we need to remove the front cover as well and service the unit. I would clean it out and then put the cover back on and fill it with new fluid after you replace the seal.

https://www.2carpros.com/articles/differential-service

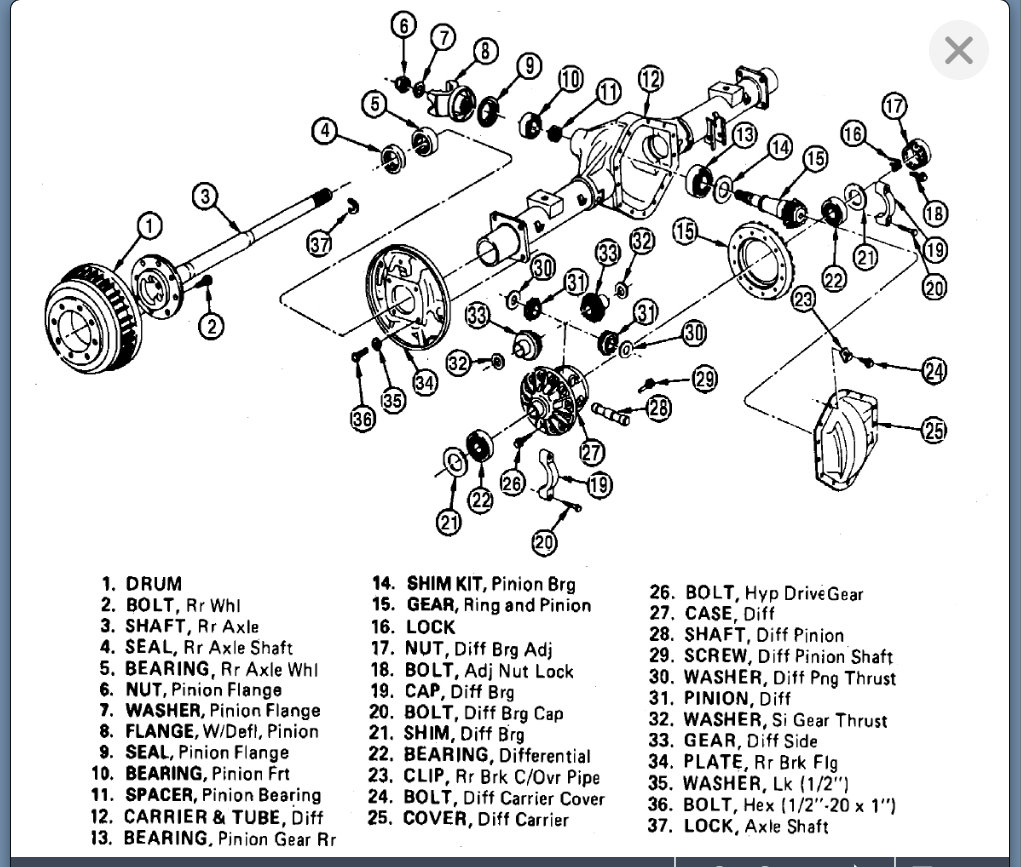

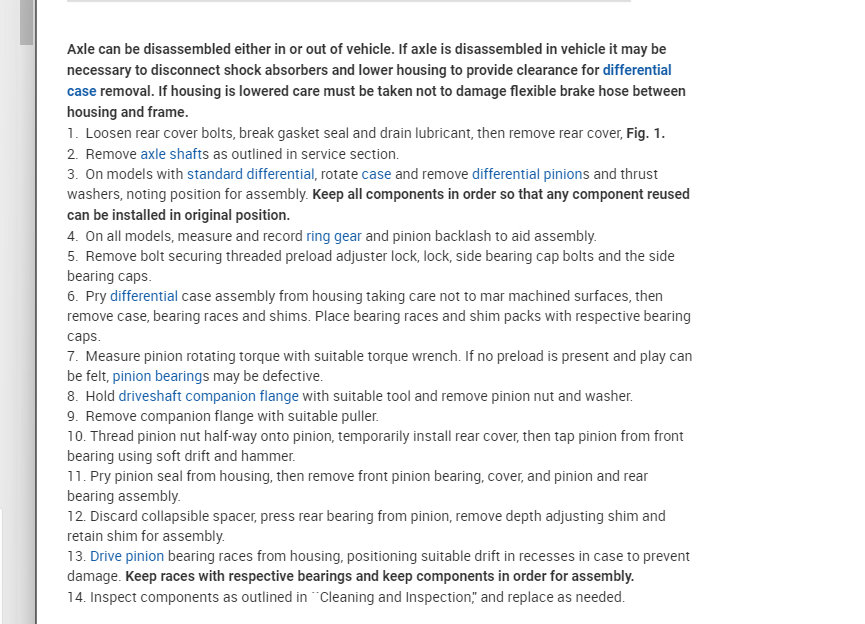

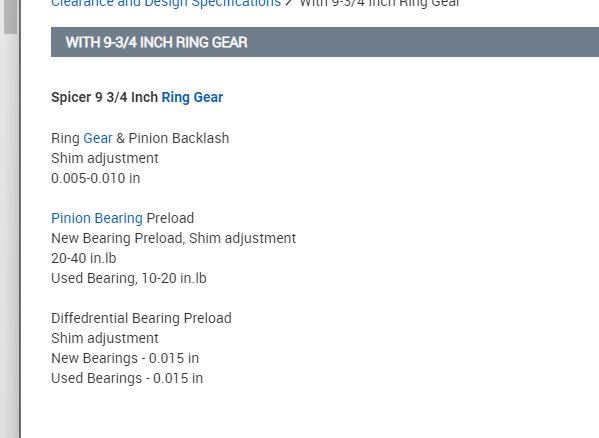

I am attaching the info below on how to replace the seal. Basically, you need to remove the drive shaft, remove the pinion nut and then the seal.

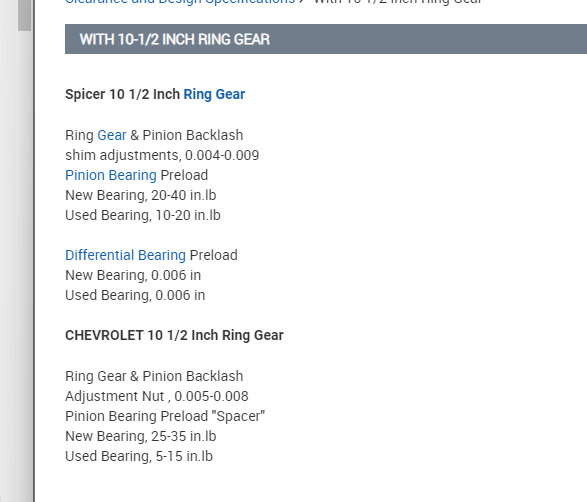

Then install the new seal as shown and then set the preload using the used bearing spec. The turning torque should be around 15-inch lbs.

Please let us know what questions you have.

Thanks

Based on this amount of oil we need to remove the front cover as well and service the unit. I would clean it out and then put the cover back on and fill it with new fluid after you replace the seal.

https://www.2carpros.com/articles/differential-service

I am attaching the info below on how to replace the seal. Basically, you need to remove the drive shaft, remove the pinion nut and then the seal.

Then install the new seal as shown and then set the preload using the used bearing spec. The turning torque should be around 15-inch lbs.

Please let us know what questions you have.

Thanks

Was this helpful?

Yes

No

+1

Wednesday, April 13th, 2022 AT 3:21 PM

There should be a tag on the unit but if the tag is gone, the only way to know is to count the teeth on the ring gear and then on the pinion and do the math to find out what the ratio is.

As for the oil, you will want to use 80W-90 gear oil.

As for the oil, you will want to use 80W-90 gear oil.

Was this helpful?

Yes

No

Thursday, April 14th, 2022 AT 3:25 PM

I got everything replaced today, and hopefully repaired. I’m nervous about the big pinion flange nut, however. I made sure to scribe it before I took it off, so I could line the yoke and flange nut up where they were before. The part that scares me is tightening the flange nut. I had to use an impact wrench to remove the nut, so I used it to tighten the nut as well. I made sure to line the scribes up, but is it possible to over-tighten it? There are a couple of threads showing out the top of the nut, and everything is solid and lined up, and feels like it did before I removed it. Am I okay? Will I damage anything by driving the truck?

Was this helpful?

Yes

No

Saturday, April 23rd, 2022 AT 9:18 PM

Great question. That is great that you marked the nut so that you can get it close. However, you are correct that it could be overtightened because you have a crush sleeve in there that if you tighten it more then you are crushing the sleeve even more and causing the pre-load to be too much.

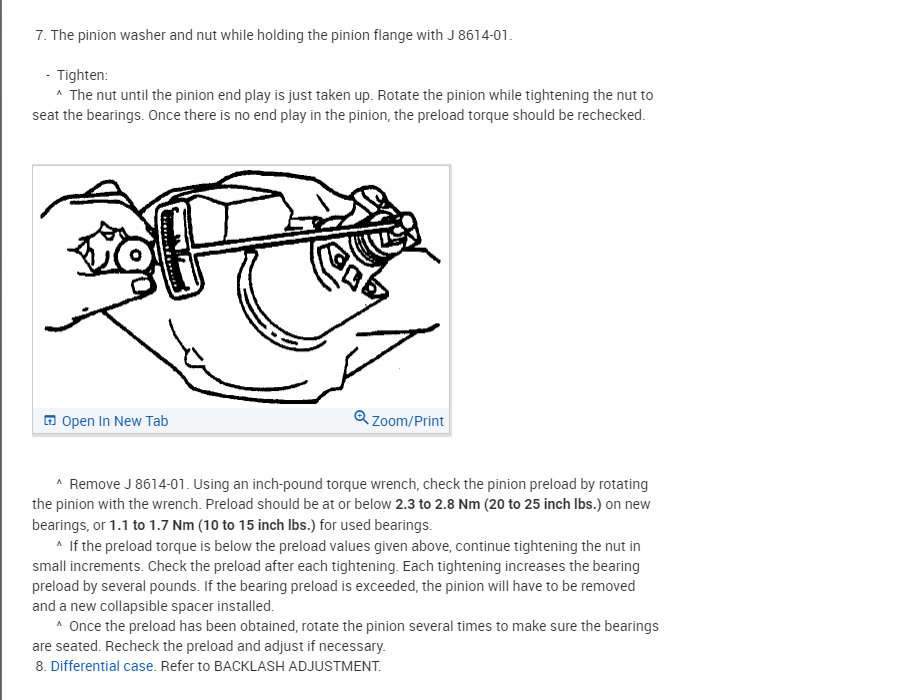

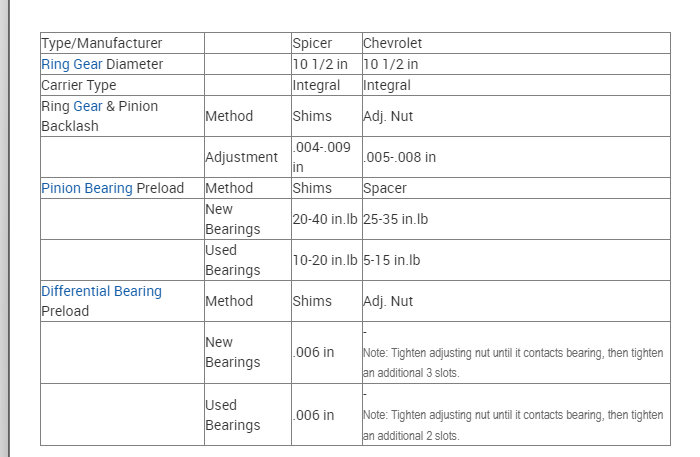

I am attaching the spec below, but you need to set the nut so that you have 5� 15-inch pounds of turning torque.

This means you tighten it down and line up the mark that you made just like you did, then you use an inch pound torque wrench on the pinion nut to turn the rear end and it should read between 5 -15-inch pounds as the pinion nut turns. In other words, you are measuring the friction or drag that the rear end has when turning from the pinion nut.

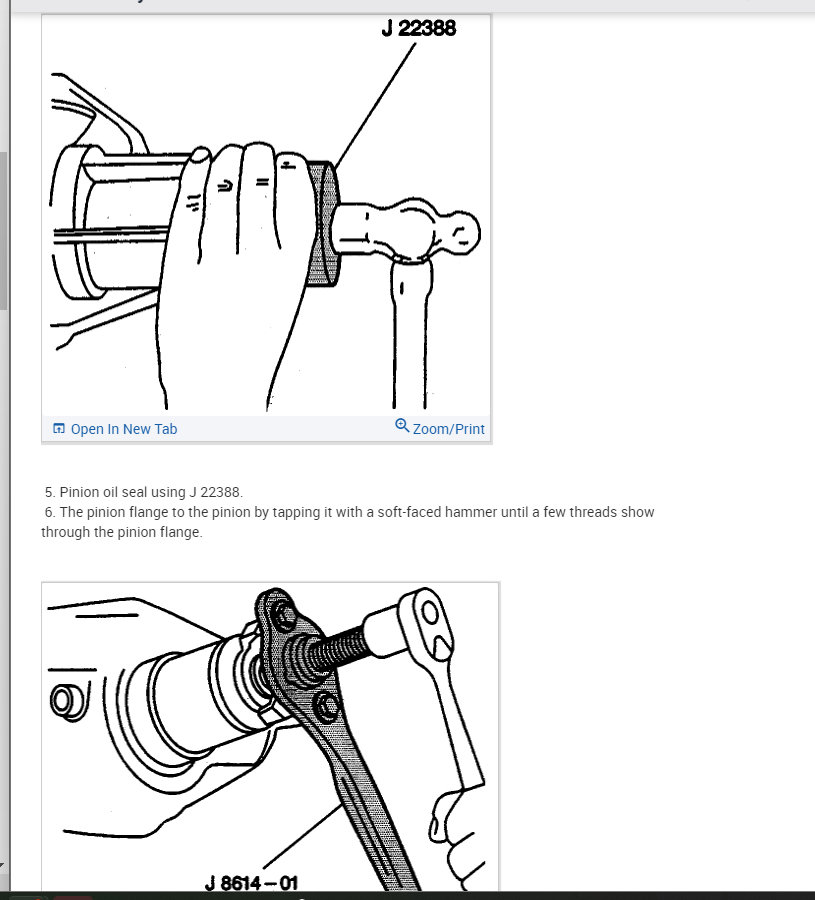

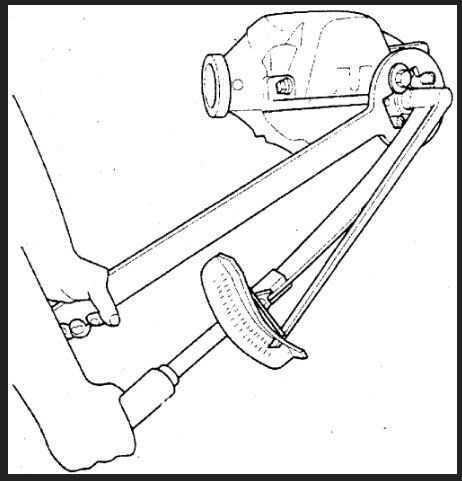

If you are in this range, then you have set it back where it was, and you are good to go. If not, then you are going to have to replace the crush sleeve and set it again. However, you cannot use an impact wrench. You are going to have to use a breaker bar on the nut and hold the flange in place with the special tool or pry bar as shown below.

I am attaching the spec below, but you need to set the nut so that you have 5� 15-inch pounds of turning torque.

This means you tighten it down and line up the mark that you made just like you did, then you use an inch pound torque wrench on the pinion nut to turn the rear end and it should read between 5 -15-inch pounds as the pinion nut turns. In other words, you are measuring the friction or drag that the rear end has when turning from the pinion nut.

If you are in this range, then you have set it back where it was, and you are good to go. If not, then you are going to have to replace the crush sleeve and set it again. However, you cannot use an impact wrench. You are going to have to use a breaker bar on the nut and hold the flange in place with the special tool or pry bar as shown below.

Was this helpful?

Yes

No

Sunday, April 24th, 2022 AT 6:51 AM

Depends on how much you over tightened it. You can drive it around the block but the more you drive it the more possible damage you are doing.

However, when you used the impact wrench to tighten it, did you run down the nut until the impact was "bouncing" on the nut and tightening it or did you stop as soon as it started bouncing on it?

If you ran it down until it was tight and then lined up your marks, then you most likely are just fine. Many people use an impact to do this, so we just need to check it before you drive it too far. However, if you want to test drive it then that would be fine.

However, when you used the impact wrench to tighten it, did you run down the nut until the impact was "bouncing" on the nut and tightening it or did you stop as soon as it started bouncing on it?

If you ran it down until it was tight and then lined up your marks, then you most likely are just fine. Many people use an impact to do this, so we just need to check it before you drive it too far. However, if you want to test drive it then that would be fine.

Was this helpful?

Yes

No

Sunday, April 24th, 2022 AT 7:48 AM

As a follow up, I’m reading that it’s about 300-400 lb ft of torque to crush the sleeve. Is that right?

As I was using the impact to tighten the nut, the yoke was sliding/being pushed back on to the gear shaft. I noticed that once the yoke stopped sliding, the impact started working harder as the nut got tighter. At that point, I stopped to see where my lines were at. They weren’t lined up yet, and I didn’t have any threads showing yet, as I mentioned in an earlier post.

I used the impact for a few more seconds, until I had threads showing, and then I “bumped” the impact a couple of times until my marks were lined up.

Also, I saw they make spacers and shims to put in place of the crush sleeve. Is that something I may have, and if so, does that make any difference?

As I was using the impact to tighten the nut, the yoke was sliding/being pushed back on to the gear shaft. I noticed that once the yoke stopped sliding, the impact started working harder as the nut got tighter. At that point, I stopped to see where my lines were at. They weren’t lined up yet, and I didn’t have any threads showing yet, as I mentioned in an earlier post.

I used the impact for a few more seconds, until I had threads showing, and then I “bumped” the impact a couple of times until my marks were lined up.

Also, I saw they make spacers and shims to put in place of the crush sleeve. Is that something I may have, and if so, does that make any difference?

Was this helpful?

Yes

No

Sunday, April 24th, 2022 AT 3:16 PM

There are a couple ways to do this, and you are correct that the torque spec is pretty high to crush the sleeve.

However, you can't solely rely on this large torque spec because we are concerned with turning torque as this is the drag that the rear end will have when it is turning.

So basically, you crush the sleeve to this large torque spec and then you have to check the turning torque. However, you are not using a new crush sleeve, so you only need to tighten the nut and then check the turning torque.

From what I am hearing you did it correctly. So, I would just check the turning torque as it sits, and I suspect you will be fine.

However, you can't solely rely on this large torque spec because we are concerned with turning torque as this is the drag that the rear end will have when it is turning.

So basically, you crush the sleeve to this large torque spec and then you have to check the turning torque. However, you are not using a new crush sleeve, so you only need to tighten the nut and then check the turning torque.

From what I am hearing you did it correctly. So, I would just check the turning torque as it sits, and I suspect you will be fine.

Was this helpful?

Yes

No

Monday, April 25th, 2022 AT 9:09 AM

Okay, great! So, I need an inch-lb torque wrench, and then I need to jack up the truck, so the back wheels are off the ground, remove the drive shaft from the yoke, and attach the torque wrench to the big pinion nut. Then turn it and measure what torque it reads. Is that right?

Was this helpful?

Yes

No

Monday, April 25th, 2022 AT 9:54 AM

That is exactly correct.

Just try to watch the dial as you are turning. The initial break away torque may be higher just to get it turning but the turning torque needs to be between 5 and 15 inch pounds. Make sure you get a torque wrench that has a dial and not a digital readout.

Just try to watch the dial as you are turning. The initial break away torque may be higher just to get it turning but the turning torque needs to be between 5 and 15 inch pounds. Make sure you get a torque wrench that has a dial and not a digital readout.

Was this helpful?

Yes

No

Monday, April 25th, 2022 AT 1:07 PM

Update: refilled the fluid and used a torque reader to turn the wheels. If I pulled it slowly and steadily, I would get like 35� 40-inch pounds. But only one wheel was spinning, or the second would barely move. However, when I pulled the wrench a bit faster, to get both wheels moving, I was getting about 10� 15-inch pounds. So, I think I’m good :)

Was this helpful?

Yes

No

Monday, April 25th, 2022 AT 7:56 PM

Yeah. Sounds like you are just fine. I noticed that as well when doing these that you can turn very slowly and get a higher reading because you are basically measuring the break away torque. However, you want turning torque so that is moving it a little faster.

Thanks again for the update. Good work. This will surely help others in the future.

Thanks again for the update. Good work. This will surely help others in the future.

Was this helpful?

Yes

No

Tuesday, April 26th, 2022 AT 7:02 AM