Okay, I will assume that you know how to take it apart so I will give you the instructions on installation. Now I do recommend that you use the old pinion bearing and hone it out so that is just fits the new pinion without having to press it on so you can set you pinion depth without pressing on and off the new bearing, once you have the right number of shims then put shims in place and press the new bearing on, make sense? If not let me know. Now here are the instruction to put it back together.

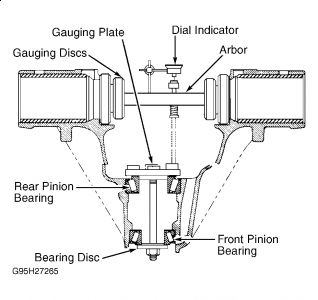

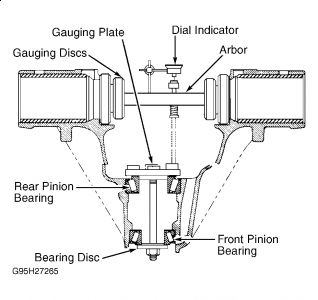

1) First set you pinion depth with a pinion depth gauge(see picture below) and side bearing preload (see picture below). You do this by using the shims that are on the old pinion and putting them on the new pinion and then use the old bearing as described above and check depth. If depth is good then using a bearing installer install the new bearing on until it is tight against the shims.

2) Install new crush sleeve onto pinion. Lube pinion bearings. Install pinion into the axle housing. Install the outer bearing into pinion using bearing installer. Hold the pinion in position from inside housing while driving bearing onto pinion. Install the pinion oil seal.

3) Install ring gear squarely into the differential case. Tighten ring gear bolts evenly and alternately to specifications (listed below). Ring gear bolts are left hand thread.

4) Lube ring gear and side gears with gear oil. Install left and right side gears and thrust washers into case as marked in disassembly. Install one spider gear into side gears and rotate until spiders are exactly opposite and rotate into place.

5) Verify shaft fits through both spiders and install thrust washers and install shaft. Install lock bolt and just snug it.

6) if side bearing were remove install side bearings.

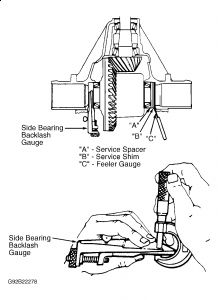

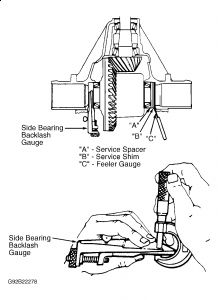

7) Lube side bearings and install races. Install different case into housing install the spacers between race and housing as they were when you took it apart with the chambered edge of spacer against the housing. Install bearing caps and loosely tighten bolt so the diff can move without falling out set side bearing preload (specs below) and then tighten everything to specs if all checks good. Now use your marking grease and then rotate the differential and make sure that the pinion rides in the middle of the ring gear. You can also use Randy's ring and pinion web and click on tech tips for more tips and if you have any questions please just ask.

Pics PInion depth

Back lash

Back lash should be .005-.009.

Side bearing preload .008

Pinion preload twenty to twenty five inch pounds to rotate pinion.

Torque specifications.

Center pin lock bolt 27 lb ft

Ring gear to carrier bolts 90 lbft

side cap bolts 60 lbft

Pinion is set with the crush sleeve on rotating torque. so once pinion preload is set the pinion nut is at the right torque.

Wednesday, September 30th, 2009 AT 10:26 AM