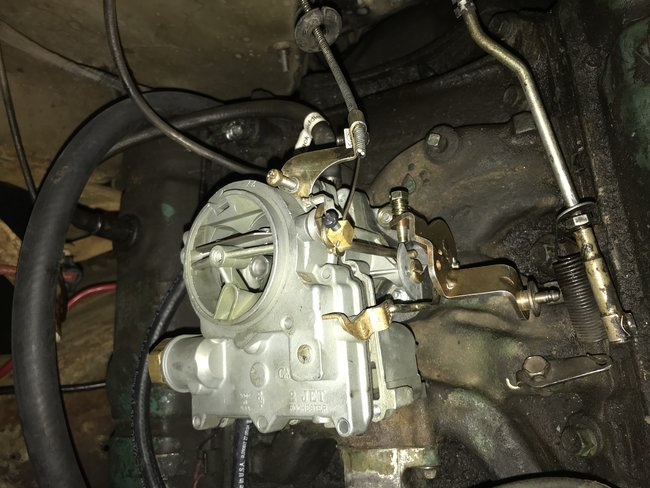

Your Distributor originally has points in it. My '46 (with Flathead 4 cyl) has similar ones

SEE PIC 1

I upgraded mine to "Pertronics", a simple electronic ignition system made for specific distributors (no more playing with points for me!)

People change stuff over the years, I wanted to know what we were dealing with, should it be a spark issue.

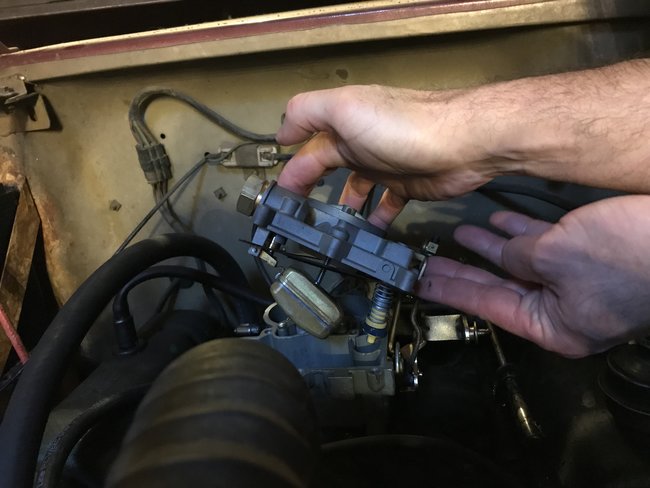

SEE PICs 2 and 3

My questions/Tests were aimed at "do you not have spark?" or "do you not have fuel?"

Obviously you have spark!

Your fuel ain't getting there, somewhere between the tank and getting into the carb throat

As we proved it will run if you dump fuel into the throat (since it ain't getting there on it's own).

Many possibilities along the way.

My firstus test would be to take a rubber line loose near the carb and turn the engine over a few times to see if fuel is pumping up to that point. Again, Outside with Fire Equipment!

Depending on your results, we will know which direction to go.

Earlier you mentioned fuel coming out of the vacuum port, this "could/maybe/ possibly" indicate your carbs float being (or was) stuck up (open, needle valve not shutting off).

This above situation might let the carbs fuel bowl overfill and fuel start running out any hole it can find.

During your carb installation, did you back hold the carbs fuel inlet with a wrench to prevent it from turning while you installed the fuel line?

If you just "cranked it on in" and the carb fitting turned (no backhold) this coulda messed up the float setting) Some call this "flooding" but actually it's "overfilling"

Enough of that

You might also try running your mix screws in till they EVER SO LIGHTLY touch bottom (turning 'em in hard WILL DAMAGE THE CARB!)

For now, back them out 2 turns (we may move 'em to 3 turns if 2 ain't enough)

For giggles, give it a whirl!

Results?

Sending you a link to look over. For now, it's a guide for later on when we can KEEP IT RUNNING! We're not to that point yet!

Please check out the mix screw adjustments that will occur later (and why!) That will be nearer the end of the thread I'm sending.

Keep in mind, I'm using my inline 6 cylinder 258 pics ('77 CJ-5) to guide this feller with a 304 (8 cylinder). THE THEORY IS THE SAME FOR YOURS!

https://www.2carpros.com/questions/jeep-cj7-1985-jeep-cj7-stalls-when-hot

OK

Rear axles on "Willy" are tapered with a keyway

I leave my wheel on and on the ground.

I remove the dust cap, cotter pin, and castle nut

I install my CJ MEDEVAC whizzy tool

Whizzy Tool- a nut with the same threads as the castle nut, this nut is welded on the outside to a 1/4 piece of flat steel. Flat steel bends outward slightly

Run Mr. Whizzy tool down until the flat steel bottoms out on the end of the axle (this keeps the threads from giving and the axle from mushrooming)

There is/ should be about an 1/8 to a 1/4 inch gap between the whizzy nut and the hub. (No gap will not let the axle move independently of the hub-in other words it not work! Gotta have the gap!)

Wheel is on the ground!

Draw back about 3-4 feet with your sledge hammer and smack the whizzy tool directly over the nut.

Usually the 1st lick does it, every now and again a second lick may be necessary.

This breaks the taper loose from the hub.

Jack up the wheel, remove lug nuts, remove whizzy tool, remove wheel, slip the hub off.

THIS WILL NOT WORK FOR '76-'86 CJs, their axles are splined and cut their own splines in the hub.

SEE PIC 4

NOTE

Your drums are pressed onto the hubs using the wheel studs, press the studs out, they will separate. A new drum can be installed in reverse order.

Send update!

The Medic

Images (Click to make bigger)

Monday, November 20th, 2017 AT 9:14 PM