There's a much better way of figuring out if a sensor is failing but it requires a scanner that can display live data. I use the Chrysler DRB3 but there are a lot of good aftermarket scanners out there that do almost as much.

Here is a guide that can show you how to scan your car

https://www.2carpros.com/articles/checking-a-service-engine-soon-or-check-engine-light-on-or-flashing

The two sensors are listed on the DRB3 as "no" or "present" to show whether those signals are being received. That makes real quick work out of a no-start condition but when you have an intermittent loss of one of the signals, there is a record feature that is used during a test drive. You press the "record" button when the problem occurs, then you can play back the data stream later to see what happened. Since that data travels through the scanner's memory, the recording actually starts a couple of seconds before you pressed the button.

The next best thing is those fault codes but the P1391 suggests the Engine Computer doesn't know which signal is being lost. Whenever it sees one signal, it knows the other one should be there too. Connector and wiring problems account for about half of the fault codes, and a defective sensor about the other half. The two sensors share a common feed wire and a common ground wire. At that point the engine would stall and not suddenly start up again. Once the short is gone, you have to turn the ignition switch off, then restart the engine to reset the 8.0 volt supply.

There are other ways for sensors to fail that do not cause the power supply to shut down. One thing that bit me was not using that paper spacer on the end of the crankshaft position sensor. After replacing a dozen transmissions, I felt confident in setting the air gap by feel, but on the 13th transmission job, that one developed an intermittent stalling problem two weeks later. In response to the intermittent loss of crank signal fault code, another mechanic replaced that sensor and solved the stalling, but I have to assume it was because I didn't use that spacer.

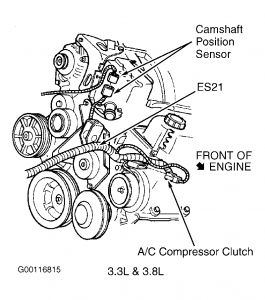

If you're going to guess at a solution, start with the crankshaft position sensor. Never replace two or more things at once. If you end up with a no-start condition due to some mistake or a defective new part, you want as few variables as possible to contend with. Camshaft position sensors are a common problem on Neons and Intrepids, but I've never replaced one on a 3.3L / 3.8L.

Monday, May 18th, 2020 AT 2:11 PM

(Merged)