Okay people, I am back, but only now finally because my internet service was down last night, again!

Jessiesjeep, "whenever it idles for any length of time (ex. In the driveway, at a red light)", what does "ex" mean? Example or except? I seriously doubt the automatic idle speed motor is the problem. It used to be real common for the air passage around the throttle blade on the 3.0L engines to become plugged with carbon but we have not seen that in over ten years thanks to the newer additives in the fuels today. I drive an old rusty trusty 1988 Grand Caravan 3.0L with 379,000 miles and have never had to clean that passage, and I always buy the cheapest gas I can find.

A real easy way to tell if the automatic idle speed motor is working is to observe engine speed at start-up. It should immediately give you an "idle flare-up" to 1500 rpm, then drop down to 800 rpm. If it does that, the AIS motor is working. If you do not get that idle flare-up and/or the engine idles too low when warm, suspect the engine computer has not yet relearned "minimum throttle" after the battery was disconnected during other service. Most mechanics will take your vehicle on a test drive at the completion of any service when the computer may have lost its memory to perform this procedure but many of them ignore it because it is so simple on Chrysler products that they leave it to the owner. It is probably the single biggest, although minor complaint after other service work was done. To relearn minimum throttle, drive at highway speed with the engine warmed up, then coast for at least seven seconds without touching the brake or gas pedals. That will meet the conditions needed to signal the computer to take a voltage reading from the throttle position sensor. From then on it knows that whenever it sees that same voltage, your foot is off the gas pedal and it has to be in control of idle speed. Once that relearn is done, you will definitely get the nice idle flare-up at start-up. If you do not, that is the time to start looking at the automatic idle speed motor. It has four coils of wire that can be monitored by the computer for integrity, and a problem there will set a fault code and turn on the check engine light, but a stuck motor armature or plugged air passage are not monitored in any way so those failures will not set a code.

"Re-flashing" a computer simply means reinstalling the software, just like on your home computer. In the past, engine computers were relatively basic and performed simple functions. Chrysler's in particular were uncommonly reliable and rarely caused a problem. They get more complex every year, and starting with the newer "on-board-diagnostics version 2 (OBD2) emissions systems mandated in 1996, they also monitor the efficiency of the catalytic converter.

Two things can happen that require a change in the computer's software. One could be the discovery that under a specific set of conditions, (road speed, altitude, engine load and temperature, etc.), Tail pipe emissions might exceed legal limits. The engineers will design a fix for that in the software, then issue an emissions recall to re-flash all of the affected computers in those vehicles. That is less expensive than replacing the entire computer which is what they would have had to do in the earlier models. GM vehicles used their famous "PROM's. That was a plug-in integrated circuit that contained all of the programming specific to that vehicle and engine, and it set the "personality" of the computer. Those were fairly easy to replace too, after they sat down to redesign it and send out to have them manufactured, tested, then shipped to the dealers.

The second reason to reflash a computer is when the software is suspected to have been corrupted. This again is very common on GM vehicles due to the huge voltage spikes their generators produce. The problems usually start when the battery gets old and loses its ability to dampen and absorb those spikes. Welding on the car can also damage computers and the software.

A third reason to reinstall software has to do with simple economics for the manufacturer. In the past they had to have a different part number computer for every possible combination of engine size, power rating, vehicle weight, vehicle options, California vs. Federal emissions, etc. That could mean a few dozen different computer choices for each car model for each year. No dealer would want to stock hundreds of computers so when you needed a new one, they had to order the correct one and wait a day or two for it to arrive. Today they only have a few different computers and it is easy and inexpensive to keep them in stock. Once installed, they connect it to the internet and download the software specific to that vehicle. You can be on the road in an hour or less.

Today, with downloading the software over an internet connection directly into the computer, there is no need to redesign any computer chips or have them manufactured. Of course with any new technology there are drawbacks. General Motors is the master at separating owners from their money after the sale. One of their many customer-unfriendly business practices is that re-flashing computers can only be done by the dealer. Independent shops are allowed to re-flash three computers, as mandated by the government, because they can affect emissions. For all of the other dozens of computers, GM refuses to release the information to anyone else, so you are tied to the dealer and that very expensive repair bill you are worried about. These business practices are one reason why so many people are saying "never again" when considering which brand of new car to buy, and GM has been losing repeat customers.

Hyundai is at the exact opposite extreme. Any independent repair shop with a laptop computer can connect those cars to the internet and the Hyundai web site, and install any software into any computer for free. Look who is putting their customers' interests ahead of profits. Chrysler and Toyota are in the middle of that range. Any independent shop can download the software for any computer except the security system. For that one, the car must go back to the dealer so they can verify it is not stolen. The only time that software download would be needed is if that computer had to be replaced. Chrysler charges $40.00 per download, and the shop must purchase a one-day, one-week, or one-year subscription to their web site, but for that subscription you get access to all their service bulletins, service manuals, diagnostic fault code descriptions, and most of the things the dealer's mechanics get to use. The point is, even though there is a charge for the service, the information is available to everyone, and it costs way less than the aftermarket service information providers charge.

Okay, getting back to your intermittent stalling problem, the code 320 is the monster clue staring at you that is proof the AIS motor is not the problem. That code has to do with an intermittently missing signal from the crankshaft position sensor or camshaft position sensor which was commonly inside the distributor. It is common for mechanics to read the code and just throw in a new sensor, and ninety nine percent of the time the vehicle is fixed, but in reality, the codes do not specify a defective sensor. All fault codes get you into the circuit or system with the problem that needs further diagnosis.

This is no different than troubleshooting cars decades ago. There were no such things as fault codes. We checked to see if fuel was squirting in, then we checked to see if we had spark. Whichever one was missing, that is the system we diagnosed. Today we can have all kinds of problems besides the simple no-start conditions. There can be a dozen sensor circuits and it would be extremely inefficient to make the mechanic look at each one every time the car came in the shop. Instead, we let the computer detect the circuit that has a problem, then the mechanic diagnoses just that one. Most of the time the sensor at the end of the line is the cause of the problem, but there could also be a corroded terminal in a connector, a wire could be rubbed through and grounding out, or a terminal could just be stretched to the point of not making good contact with the mating terminal. To add to the confusion, some of the terminology can be misleading. An engine computer may use a "distributor reference signal" for an engine that does not use a distributor. The signal provides the same information but it comes from a different source or different type of sensor. On your engine, there is indeed a distributor, and code 320 refers to the camshaft position sensor that lives in it. You said your mechanic replaced the crankshaft position sensor which provides the same type of signal but it is actually in a different place and develops its signal from a different source. Either one of those sensors can become heat-sensitive and fail intermittently. They will often work again once they cool down in about an hour.

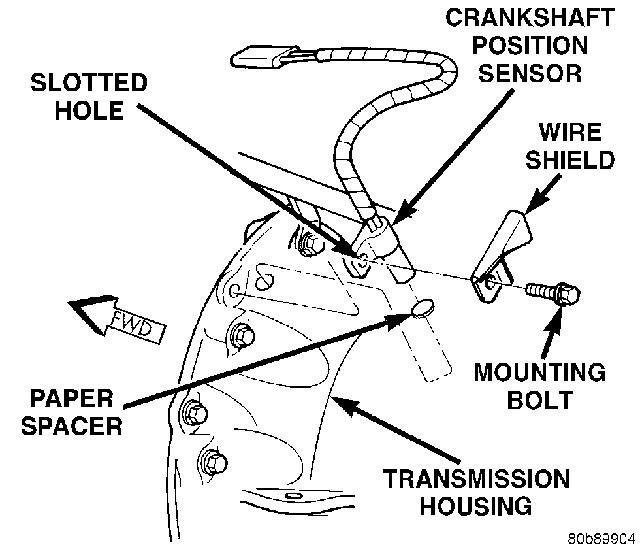

Another problem to be aware of when a new crankshaft position sensor is installed is they require the use of a thick paper spacer on the end to set the critical air gap. That spacer slides off when the engine is started but by then its job is done. Many aftermarket sensors have a thin plastic rib molded to the end to set the gap. It wears away when the engine is running so if that type is removed and reinstalled, it is supposed to have the remaining part of the rib cut off and you use a paper spacer. I had to reinstall that sensor after replacing transmissions. After doing a half dozen of them, I got so "good" at setting the air gap on those sensors that I didn't need the spacer. I learned later that on the thirteenth one, the owner developed intermittent stalling two weeks after I replaced his transmission, and a different shop read the fault code for that sensor, replaced it, and it solved the problem. Now I suppose it is entirely possible the sensor did become heat-sensitive and decide to fail, but I suspect it was due to my not setting the gap properly. I was going to suggest that is what happened on your Jeep, except the fault code is related to a different sensor. I suspect you have a failing camshaft position sensor. That is a bolt-in item, but I never replaced one so I am not certain, but I do not think there are any special procedures to follow or air gap to set.

Now, if you will excuse me, I have not eaten in over an hour! I am going to grab a slice of cheese and wash it down with some milk.

Wednesday, July 6th, 2011 AT 8:18 PM