Introduction

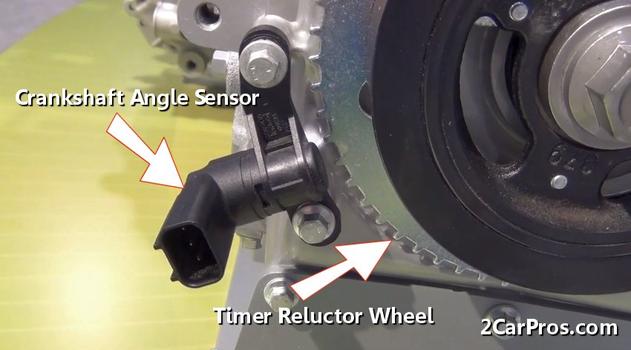

The crankshaft position sensor (CPS) is a critical component in modern automotive engines and is used to reference crankshaft rotation as the engine is running while supplying feedback data to the main engine computer. This sensor is mounted near the crankshaft, flywheel or in the engine block depending on the manufacturers design. As the crankshaft spins it creates an electrical pulse pattern that changes with engine speed. This wavelength controls computer output circuits such as fuel injector pulse width, camshaft and ignition timing adjustments. The reluctor or stator wheel is fastened to the crankshaft which is used by the sensor.

Function of a Crankshaft Position Sensor

The primary function of a crankshaft position sensor is to determine the exact position of the crankshaft in its rotation cycle. This information is essential for:

- Determining ignition timing

- Controlling fuel injection timing

- Synchronizing camshaft position with crankshaft rotation

- Detecting engine misfires

3 Types of Crankshaft Position Sensors

- Magnetic Inductive (Variable Reluctance) Sensor: This sensor consists of a permanent magnet, coil, and soft iron core.

- Hall Effect Sensor: This type uses a semiconductor chip that generates a digital signal when exposed to a magnetic field which requires an external power source.

- Optical Sensor: Optical sensors use a light-emitting diode (LED) and a photodetector to detect interruptions.

Crankshaft Sensor Names Can Vary

This sensor can go by different names depending on the manufacturer, but perform the same function.

- Crankshaft Position Sensor (CKP Sensor) – The most widely used term.

- Crank Position Sensor – A shortened version of the name.

- Engine Speed Sensor (ESS) – Refers to its role in detecting engine RPM.

- RPM Sensor – Used in some service manuals.

- Crank Angle Sensor (CAS) – More common in older Japanese vehicles.

- Crankshaft Reference Sensor – Used in some GM and European vehicles.

- Crankshaft Timing Sensor – Describes its function in timing.

- Impulse Sensor – Used in some German vehicles.

- TDC Sensor (Top Dead Center Sensor) – Used when the sensor is specifically positioned to detect TDC.

- Pick-up Coil – Some older vehicles with distributor-based ignition systems use this term.

How a Crankshaft Sensor Works

A crankshaft position sensor uses a magnetic coil mounted inside a plastic housing while supplying an electrical connector to transfer data to the computer. The computer also uses this sensor to gather misfire data due to the temporary slowdown of the crankshaft while the misfire occurs. When the starter is engaged the computer uses the crankshaft position sensor to confirm the engine is actually cranking over. Once this confirmation is received the computer will signal various relays such as the fuel pump relay and ignition systems that the engine ready to start. When replacing a crankshaft position sensor you may need to recalibrate or relearn the sensor function using a automotive computer scanner.

Conclusion

The crankshaft sensor is at the heart of the engine computer monitoring and control program, and is the most important part in the operation of the ignition, camshaft timing and fuel injector adjustments.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.