Welcome back:

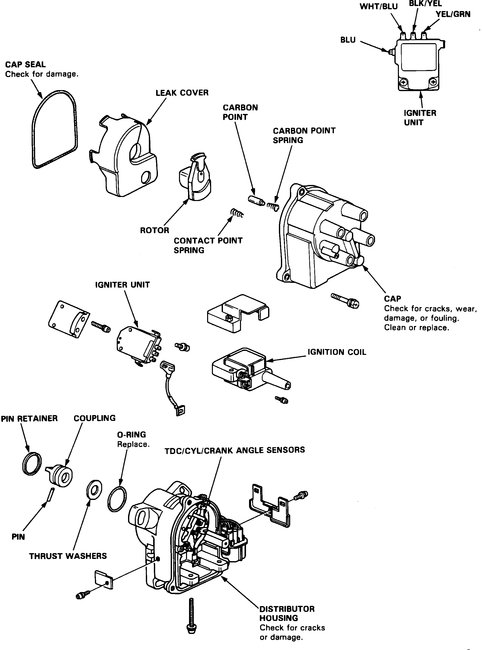

If there is no spark, either we have an issue in the ignition switch or the crank angle sensor is bad in the distributor.

The crank angle sensor is in the distributor. I attached the directions for replacing it. I'm not saying for sure it is bad, but I suggest taking things apart and inspect for corrosion or damage.

+++++++++++++++++++++++++++++++++++++++++

1991 Honda Accord L4-2156cc 2.2L SOHC

Procedures

Vehicle Powertrain Management Sensors and Switches - Powertrain Management Sensors and Switches - Computers and Control Systems Crankshaft Position Sensor Service and Repair Procedures

PROCEDURES

DISTRIBUTOR REMOVAL

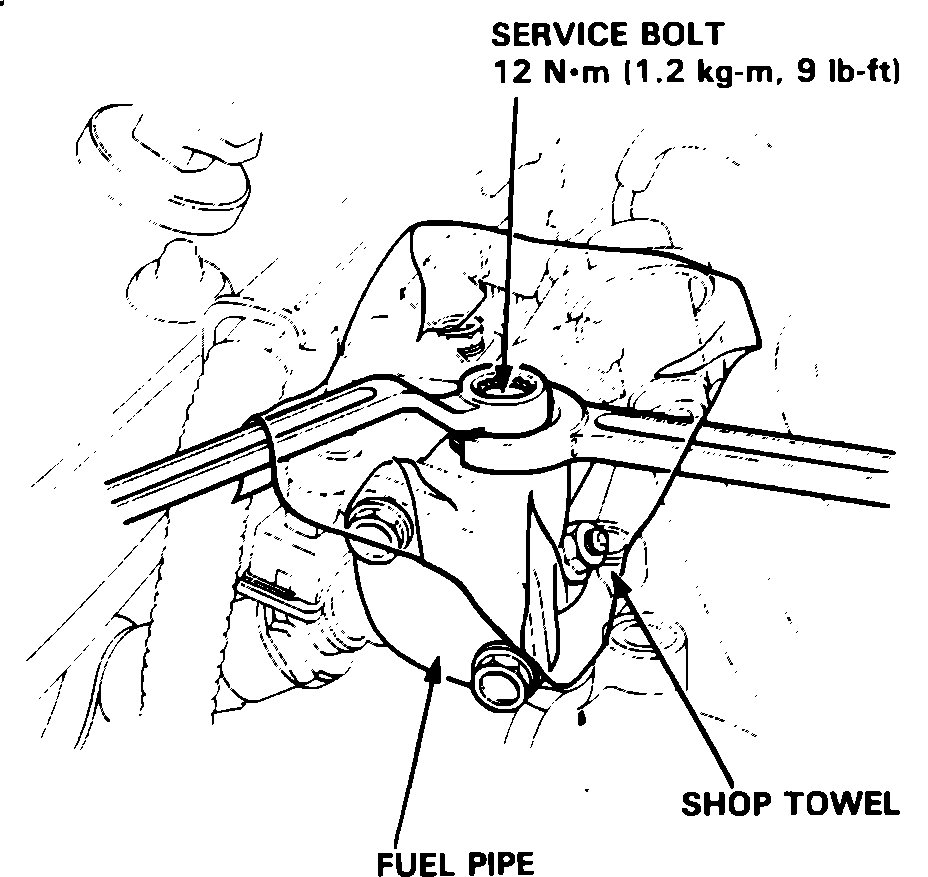

1. Disconnect the 2-P and 8-P connectors from the distributor.

2. Disconnect the spark plug wires from the distributor cap.

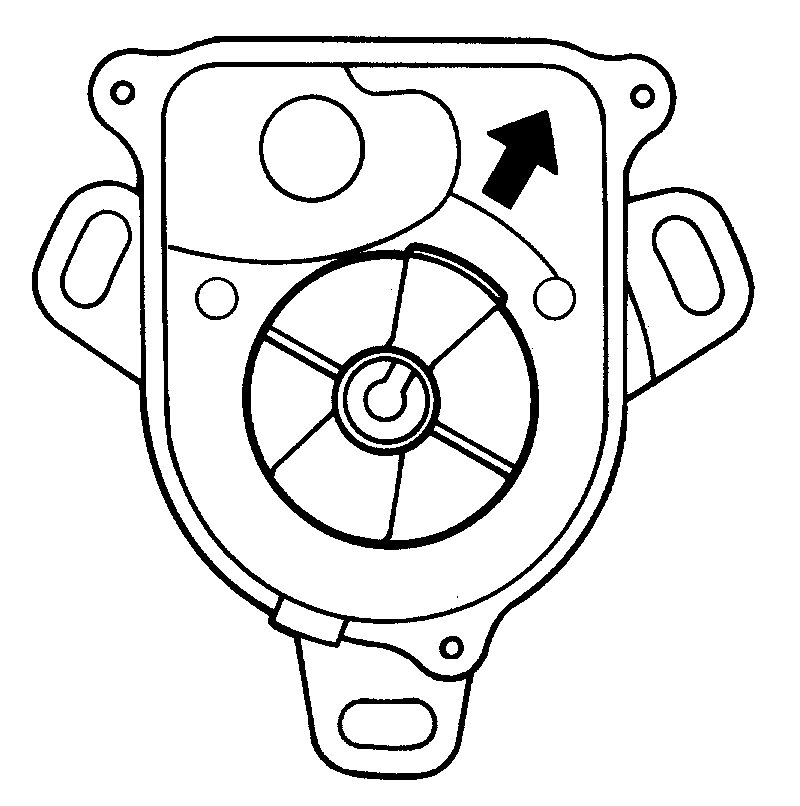

Distributor Connectors

Pic 1

3. Remove the distributor hold-down bolts, then remove the distributor from the cylinder head.

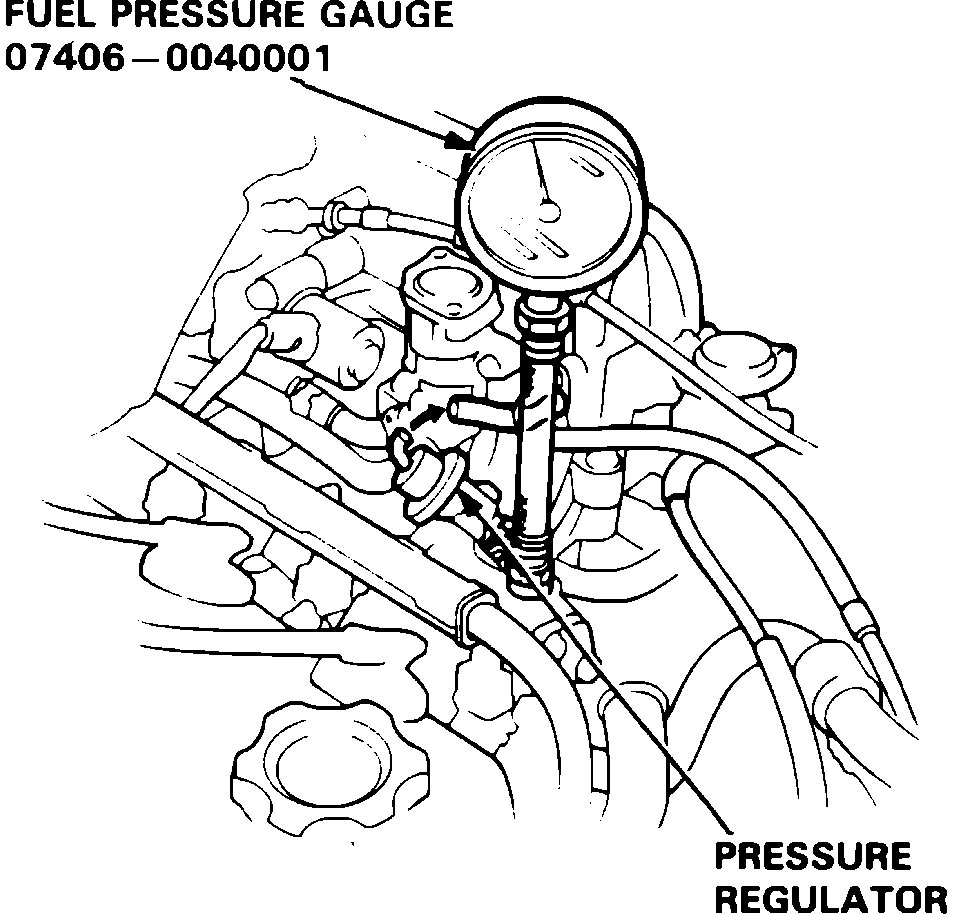

DISASSEMBLY

Distributor Explosion

pic 2

4. Use the exploded view image for distributor disassembly.

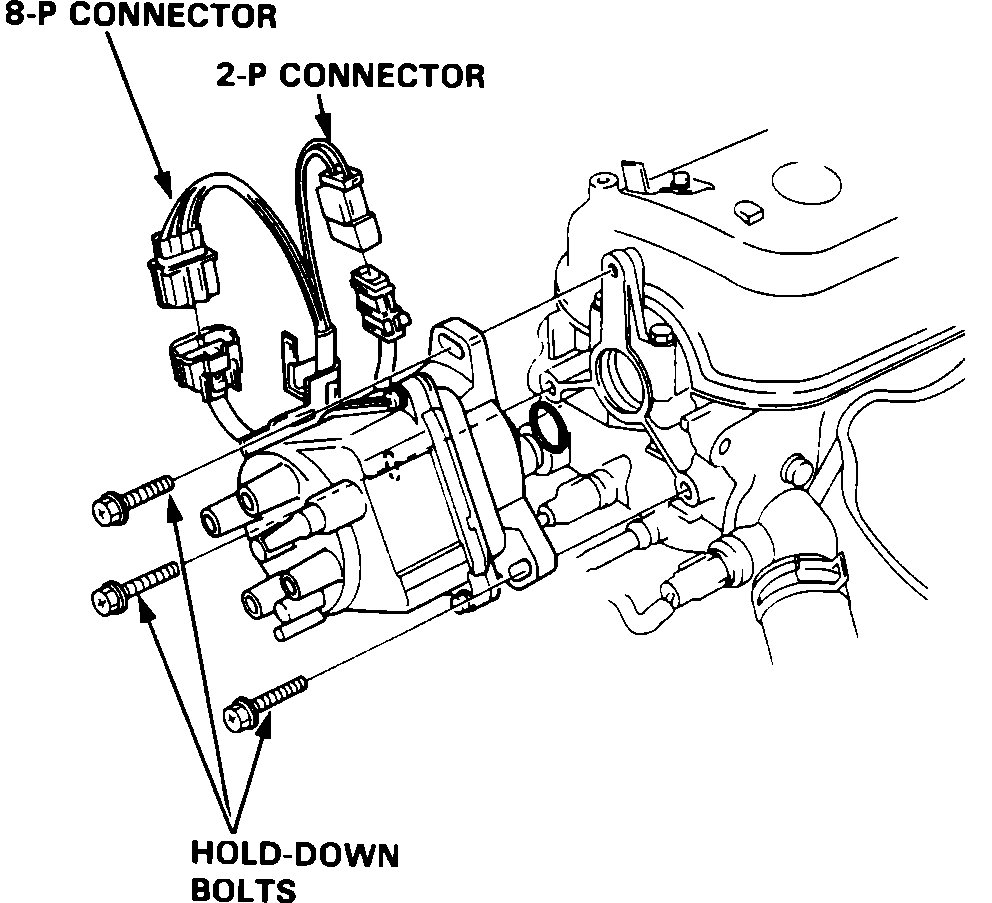

REASSEMBLY

pic 3

Reassemble the distributor in the reverse order of disassembly.

1. Install the rotor, then turn it so that it faces in the direction shown (toward the No.1 cylinder).

2. Set the thrust washer and coupling on the shaft.

Pic 4

3. Check that the rotor is still pointing toward the No.1 cylinder, then align the index mark on the housing with the index mark on the coupling.

4. Drive in the pin and secure it with the pin retainer.

INSPECTION

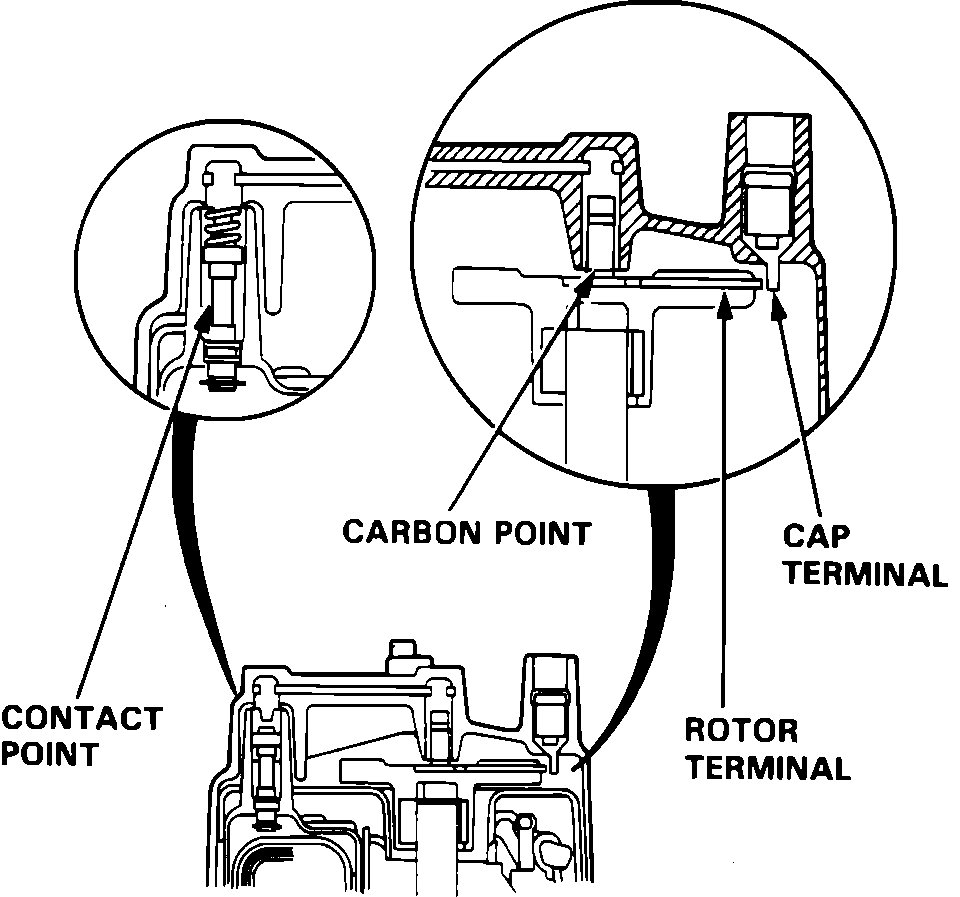

Cross Section Of Distributor

pic 5

5. Check for rough or pitted rotor and cap terminals.

6. Scrape or file off the carbon deposits. Smooth the rotor terminal with an oil stone or #600 sandpaper if rough.

7. Check the distributor cap for cracks, wear and damages. If necessary, clean or replace it.

REASSEMBLY

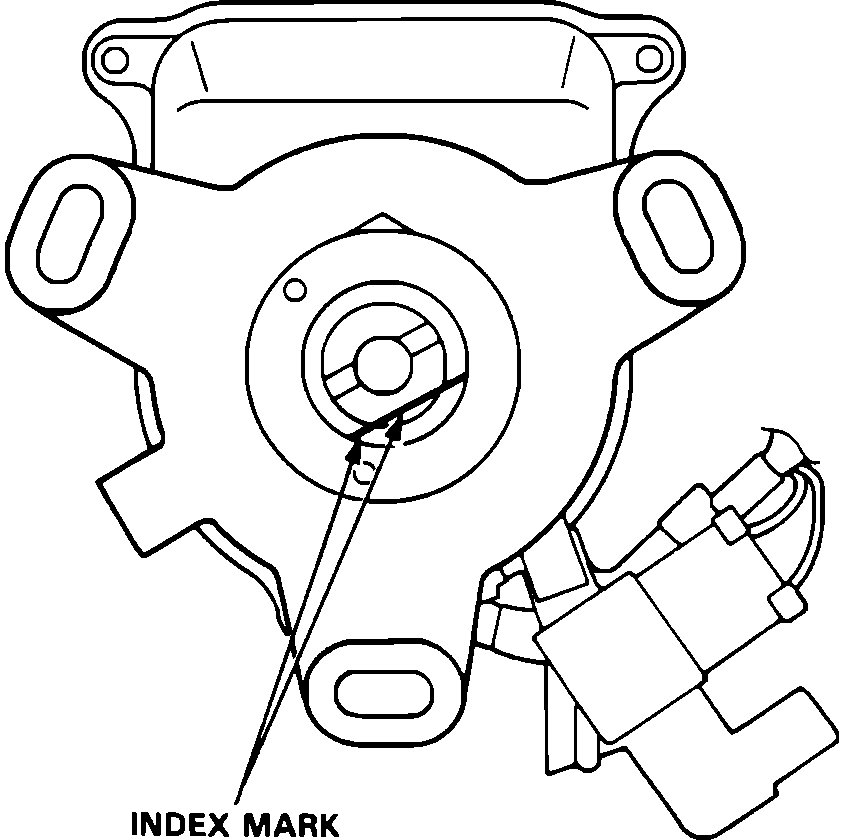

Rotor Position

pic 6

8. Install the rotor, then turn it so that it faces in the direction shown (toward the No. 1 cylinder).

9. Set the thrust washer and coupling on the shaft.

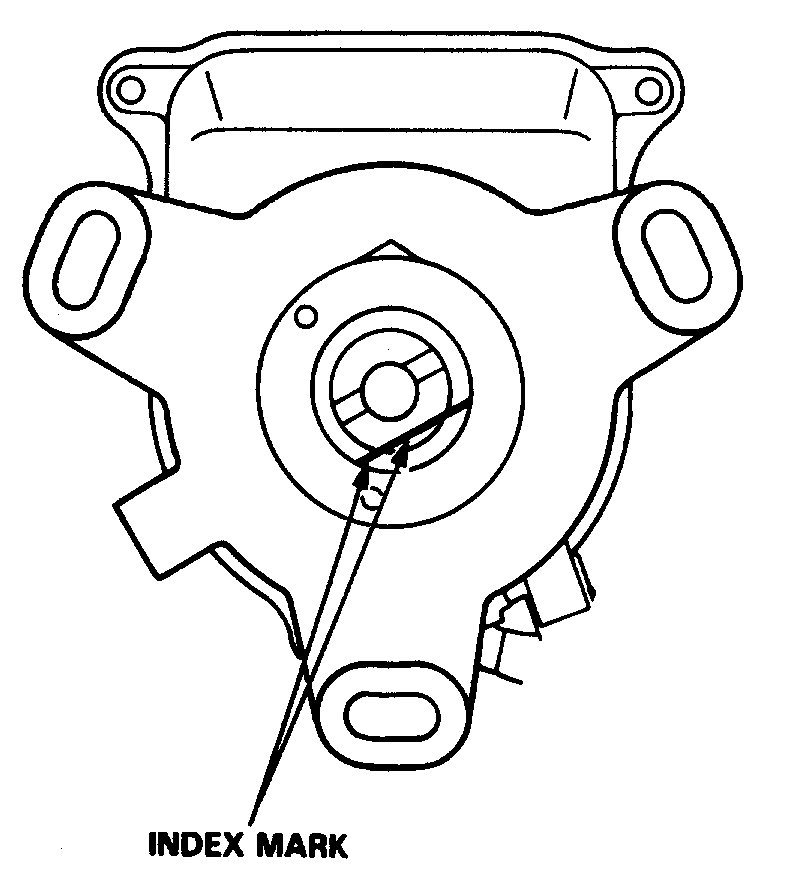

Distributor Index

pic7

10. Check that the rotor is still pointing toward the No. 1 cylinder, then align the index mark on the housing with the index mark on the coupling.

11. Drive in the pin and secure it with the pin retainer.

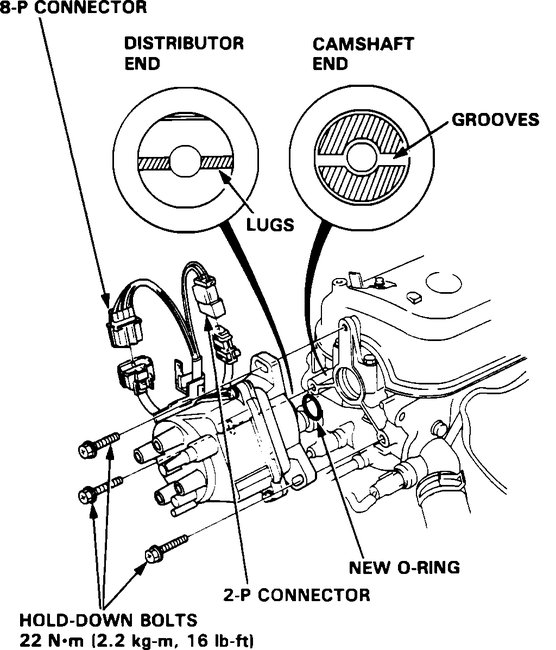

INSTALLATION

12. Coat a new 0-ring with engine oil then install it.

13. Slip the distributor into position.

NOTE: The lugs on the end of the distributor and its mating grooves in the camshaft end are both offset to eliminate the possibility of installing the distributor 180° out of time.

Distributor Installation

pic 8

14. Install the hold-down bolts and tighten temporarily.

15. Connect the 2-P and 8-P connectors to the distributor.

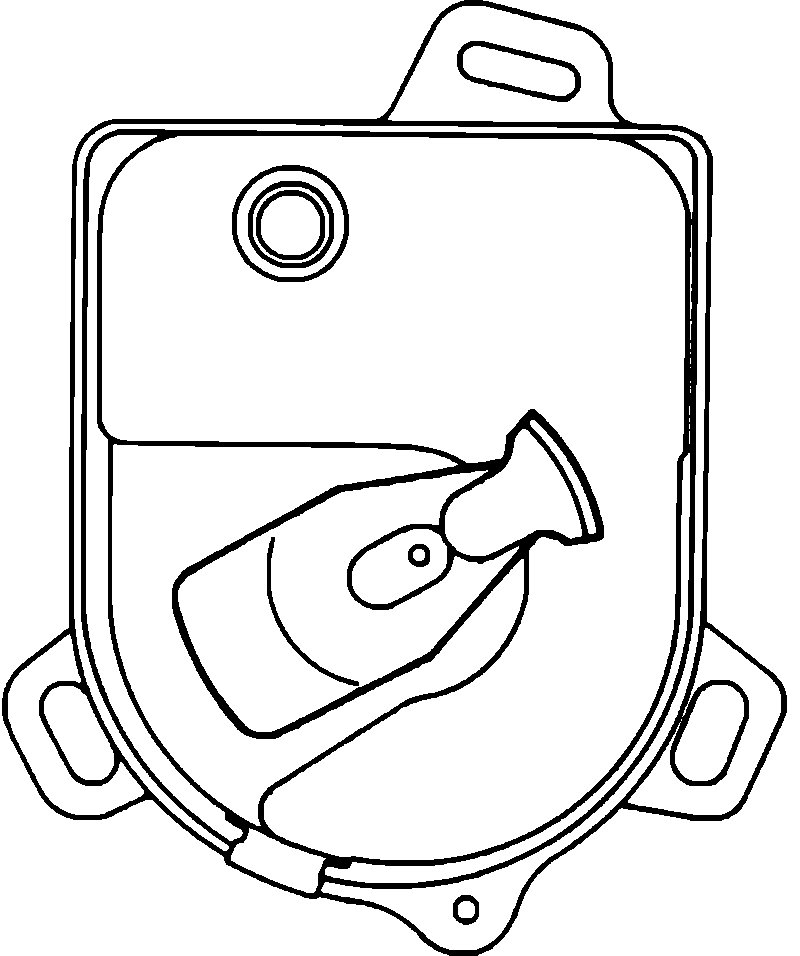

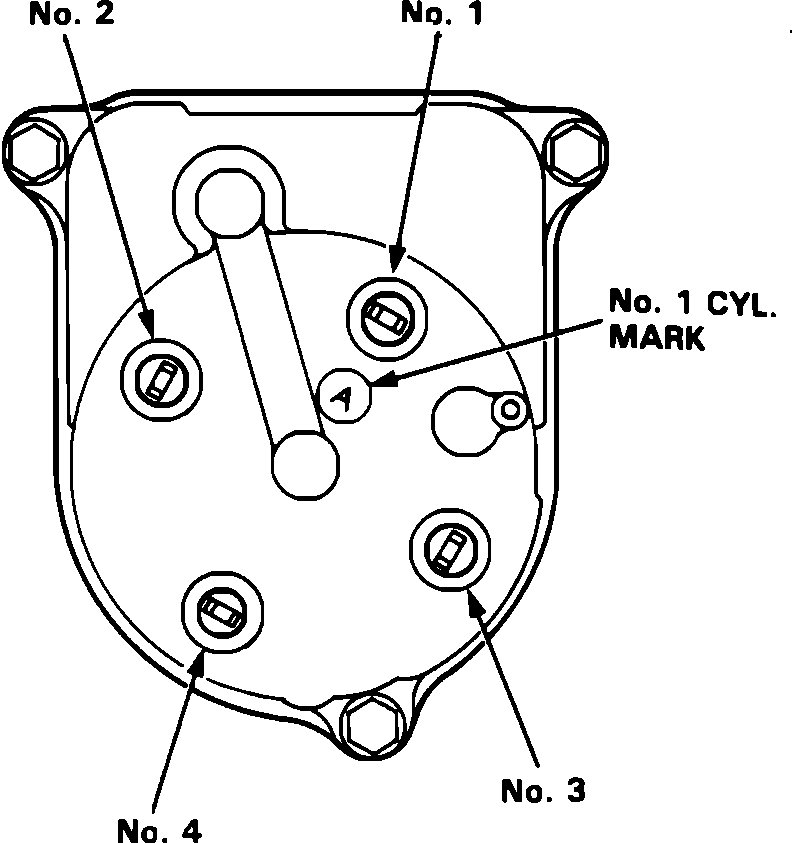

Distributor Cap Typical

pic 9

16. Connect the spark plug wires as shown.

17. Set the timing with a timing light as shown in ADJUSTMENT PROCEDURES.

18. After adjusting, torque the hold-down bolts, then install the cap on the bolt.

Torque: 16 ft. Lbs (22 Nm)

Let me know what you find.

Joe

Images (Click to make bigger)

Sunday, October 6th, 2019 AT 8:09 PM