Hello LESLIE PAYNE,

That link that I sent for the coolant pressure tester was for informational purposes only. I did not expect you to be able to purchase it from them. I assume in your situation you will need to use the resources available to you in your country. I have added a picture of the coolant system pressure tester for your reference.

Okay, if you say you checked the transmission fluid and it is good, then that is good.

However, transmission fluid needs to be checked when the car is running and up to operating temperature. If it has sat overnight and you are checking it before you drive it, most of the fluid will be in the transmission pan. Also, as transmission fluid heats up it will expand, so once you get it to operating temperature it will be at the wrong level.

Valvoline Max Life is a universal fluid. According to Valvoline, it is compatible with 95% of vehicles on the road today. It is far from specific. However, given your situation, I understand why you had no choice but to use it.

If the engine is not running correctly, then the transmission will not respond correctly. So, let's try to get the engine running better and see how the transmission responds.

For more specific help with your transmission, I suggest starting a new question specifically for your transmission.

A/C line:

Okay, I see what you were saying not about the tape. That was awfully nice of them to leave those off.

I did notice on the same hose we are talking about close to the radiator it seems to be covered in what looks like rust. This could be the radiator leaking and blowing back into the engine compartment as you drive down the road.

Water alone does not provide enough cooling for your engine. I understand coolant is illegal in your country, but there is that hot rod guys use because their vehicles are usually seasonal, so they don't need antifreeze. Those guys use something called Water Wetter. This will help regulate temperatures in the engine, reduce the surface tension of the water, improves heat transfer, reduces cylinder head temperature, and provides rust and corrosion protection. It also does not contain ethylene glycol, the main ingredient in antifreeze. You will have to look into it, but I think it may be a good middle of the road solution for you.

I found some on Amazon for you. I have also added a photo of this for you. Here is the link:

https://www.amazon.com/Red-Line-80204-Water-Wetter/dp/B000CPI5ZK/ref=asc_df_B000CPI5ZK?tag=bingshoppinga-20&linkCode=df0&hvadid=79852087642110&hvnetw=o&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4583451664389398&th=1

Now back to wiring:

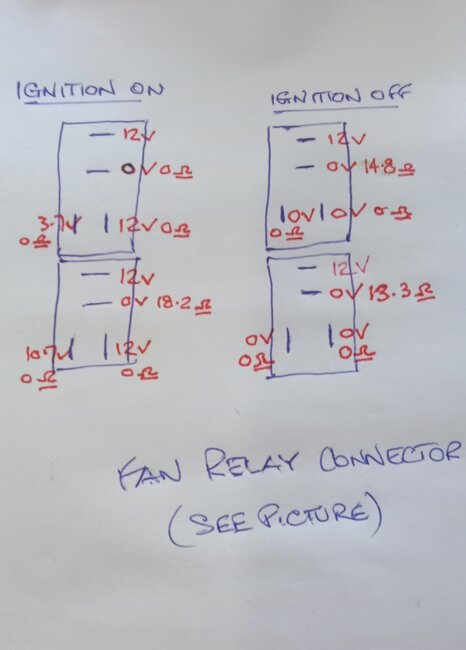

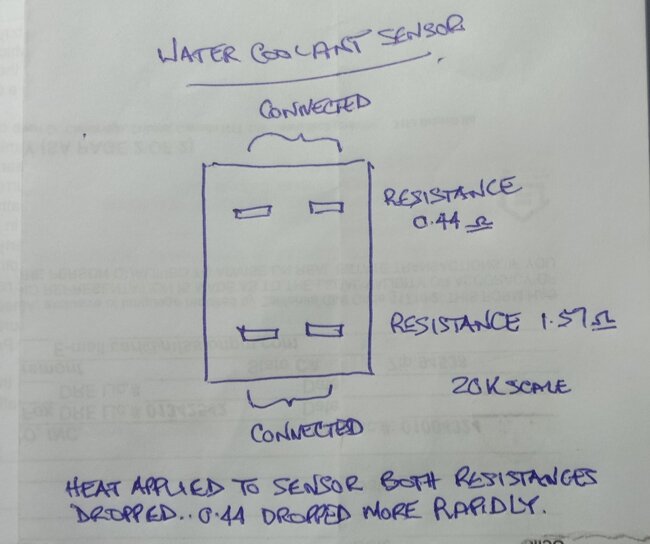

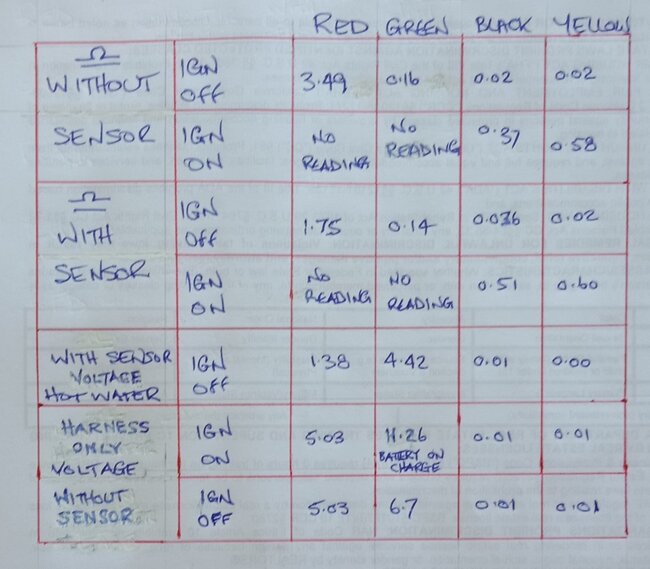

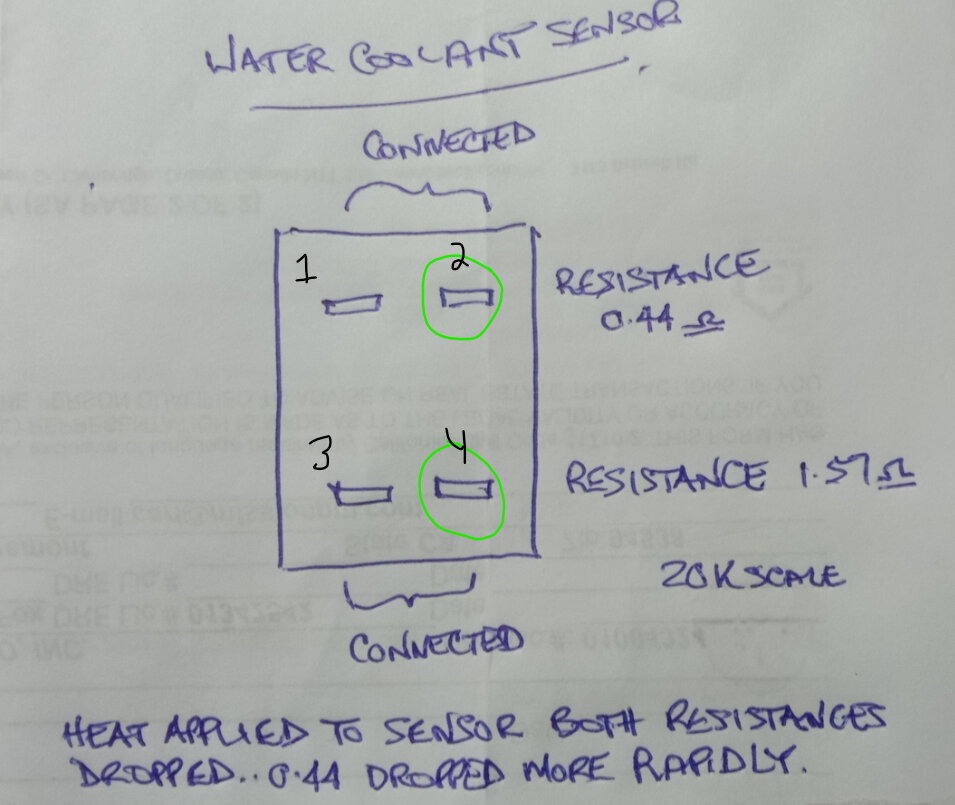

Thank you for giving me all those readings. They are very helpful, and the illustration was great as well.

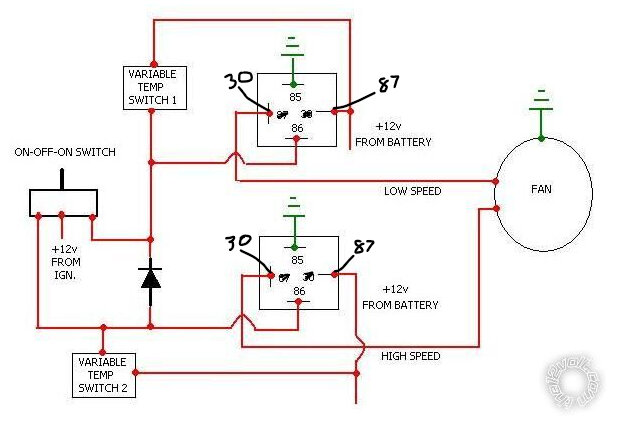

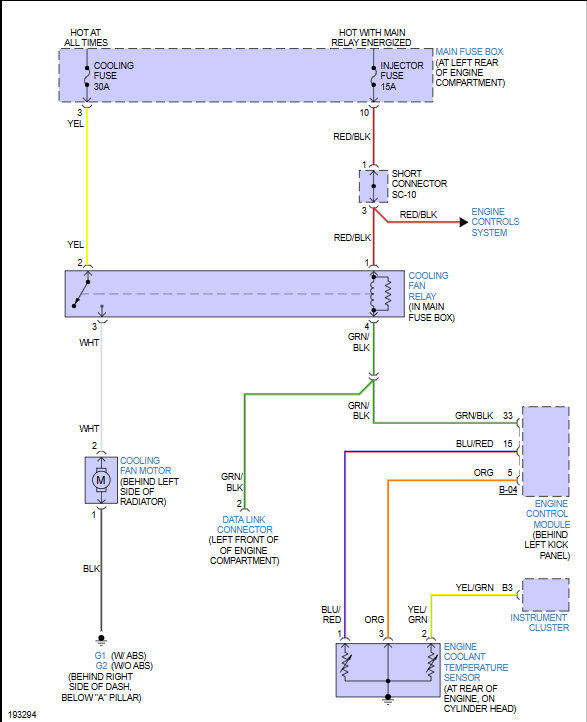

As for your question about two switches in the cooling system - because you have a coolant temperature sensor and a resistor by the radiator, technically you have two switches.

However, if the resistor is bad the fan will only work at one speed, so it should not keep the fan from working. It is good that you tested it nonetheless.

When testing for resistance, we only check part of the circuit or wire. We cannot test resistance on live circuits (i.e. ones with voltage present). The voltage will skew the results of the test because the meter is trying to use a voltage drop to calculate the resistance of what we are testing. This is to look for either high resistance or a break in a connection/circuit.

Since we observed 12 volts and we have a 12-volt circuit, we don't need to measure resistance. We can infer from our voltage reading that there is no voltage drop, meaning there is little to no resistance in that part of the circuit.

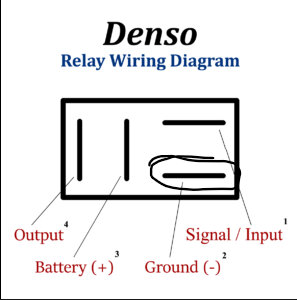

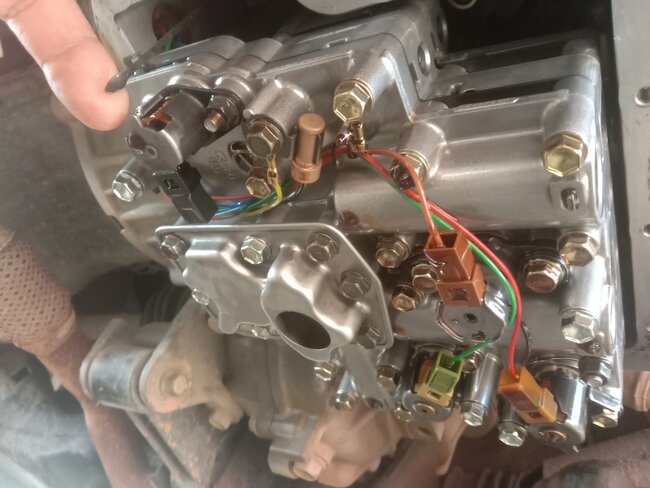

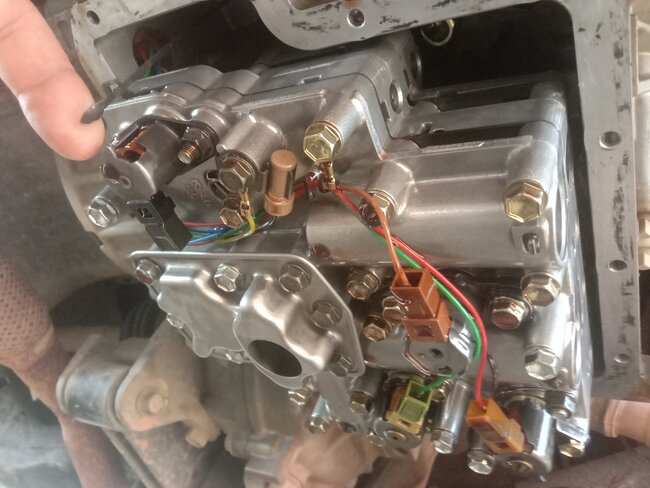

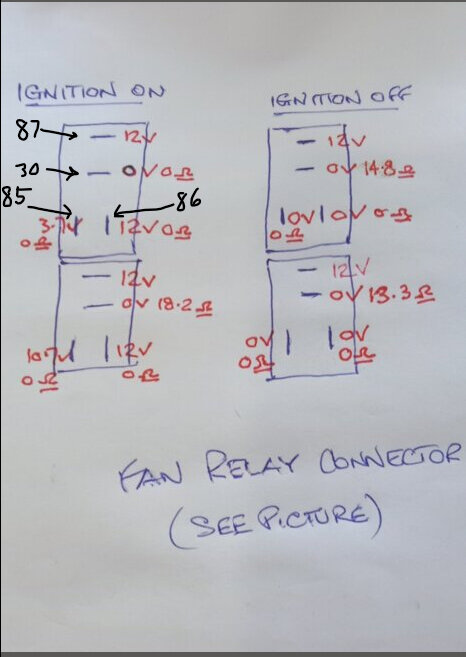

What we know from our tests: (terminal identification)

87-12(+) Hot-This terminal has a constant 12-volt source whether the key is on or off.

30-Output to Device- In our case to the fan.

86-12 volt switched- This terminal only has power with the key on.

85-Ground/Signal- This terminal is controlling the ground side of the circuit, completing it using the PCM or it goes directly to the temperature sensor.

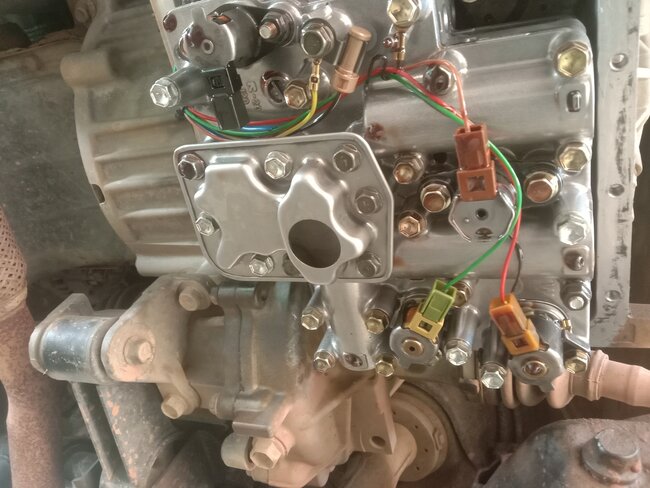

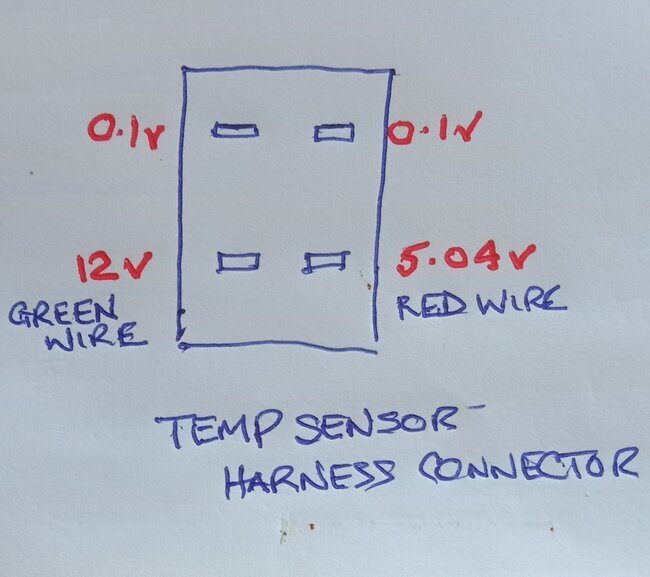

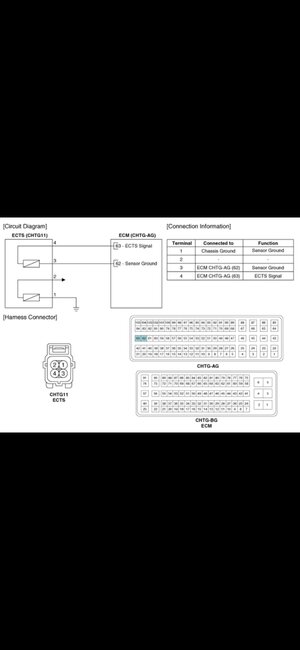

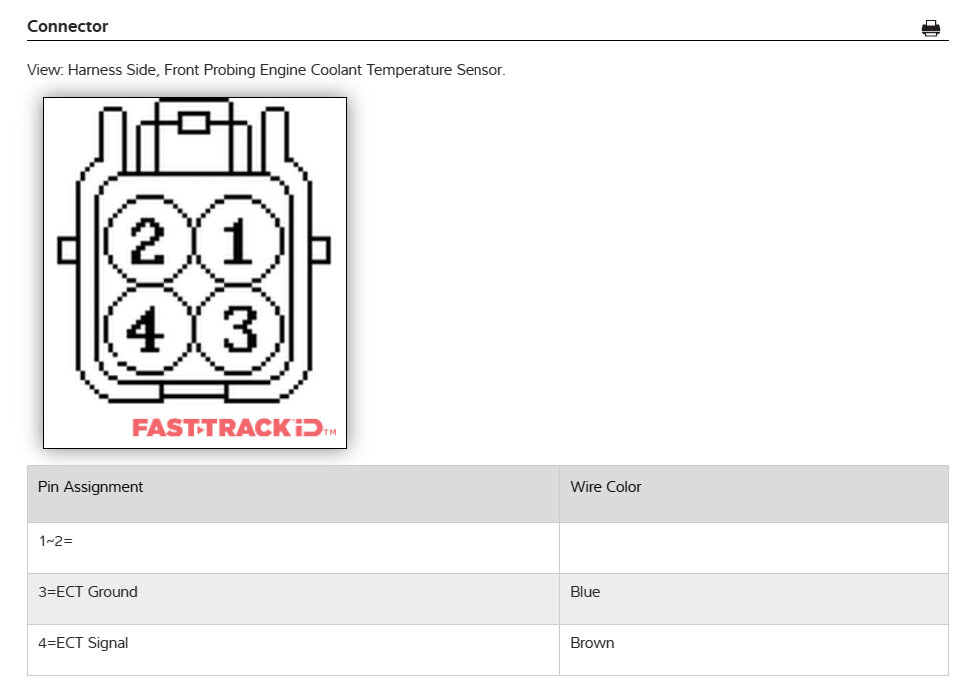

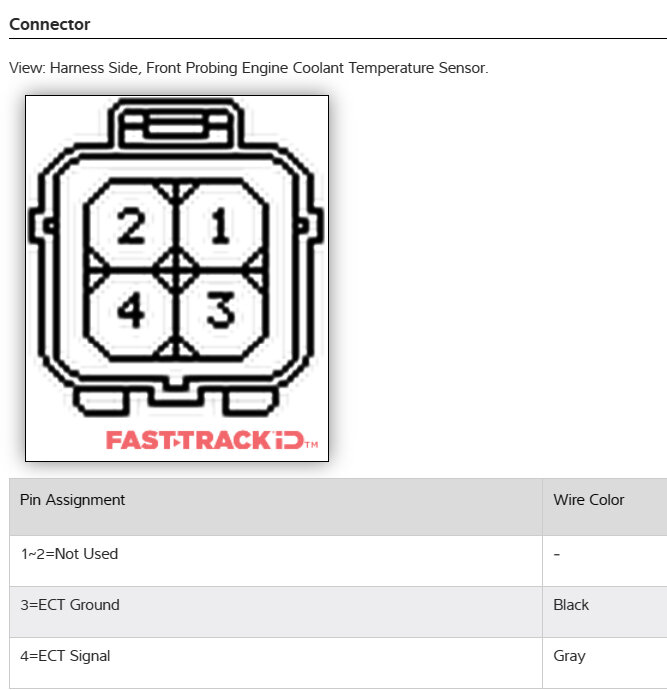

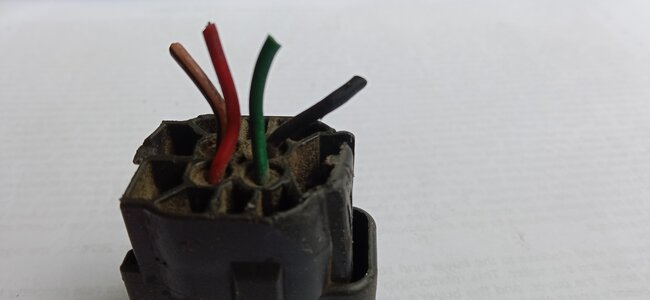

Now that we have pretty much identified the fuse relay area, let's see if we can identify the wires on the temperature sensor.

We also know that the fan power and ground are good because the fan operates from the relay center when you jumped terminals 87 and 30.

We know that the relays are good because you tested those.

We also know that both power supplies are working properly.

So, the last thing that we need to figure out is where the coolant temperature signal to the relay is coming from. Then we can better understand why the fans are not turning on.

Test: (done using voltage setting only)

First, unplug the sensor and test at the connector on the harness. See if you can find a 5-volt source like you did before for the TPS. You may have two 5-volt sources like you did before. Now record your findings. We will see if one goes away in the next test.

Second, plug the sensor back in and back probe the connector and do all the same tests and record your findings.

Lastly, get the vehicle up to operating temperature and again perform the same tests the same way and record your findings. Once the vehicle is warmed up, you may turn off the engine, but turn the key back on the take your measurements. Since the coolant is still hot, it should still give you an accurate reading.

Let me know what you get for results. These tests should help us identify the 5-volt reference from the PCM and any signal wires. Then we should be able to determine the ground as well.

Some info for you:

There are two types of coolant temperature sensors generally. One is a positive thermal coefficient (PTC). This sensor, as the temperature in the engine rises, the resistance also rises which will result in a lower voltage reading on a signal wire as compared to when we previously tested when the engine was cold.

Negative thermal coefficient (NTC) - this sensor, as the temperature in the engine rises, the resistance will decrease resulting in a higher voltage reading than when it was cold.

Because you are using only water, you may have a lot of corrosion inside your cooling system. So, I would remove the temperature sensor and see if it has any rust or corrosion build-up on it. If it does, see if you can clean it. This will keep the sensor from reading the temperature properly and could be the cause of the fans not working. Before you remove it, make sure you either have some nylon thread tape or some thread sealant so when you reinstall it, it does not leak.

If it is severely corroded, completely draining and refilling the cooling system with fresh water would be a good step to try to remove as much rust a possible from the system.

Here a few articles concerning electrical testing and some other resources which I thought you may find useful:

https://www.samarins.com/glossary/coolant-temperature-sensor.html

https://www.fluke.com/en-us/learn/blog/electrical/what-is-ohms-law

Please let me know if you have any questions about these tests or I can help guide you.

Over the last 6 days of talking to you, you seem to have a pretty good handle on testing so I think you'll be fine but let me know if I can assist.

Thank you,

Brendon

Images (Click to make bigger)

SPONSORED LINKS

Sunday, July 16th, 2023 AT 2:53 PM