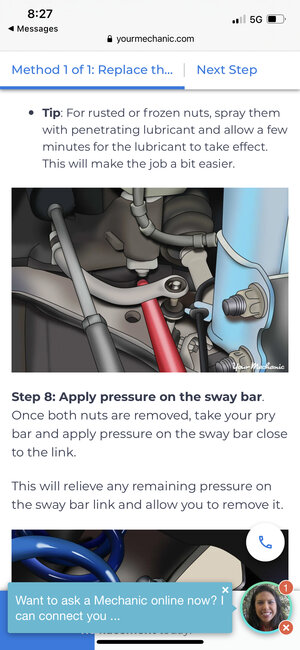

There's a number of different designs for attaching the anti-sway bar to the control arms, and for some of them, you were told correctly. The bar has to be moved to allow the link to be inserted, and the link on the other side prevents you from doing that. Almost all links are easier to replace when both are removed at the same time.

This article provides more information:

https://www.2carpros.com/articles/how-to-replace-a-sway-bar-link

but here they are replacing the most common design, and loosening the other link is almost a requirement. With this design you almost always get both links in the kit because the bushings all wear out at the same rate. You aren't saving anything by replacing just one as the other one is going to fail shortly too.

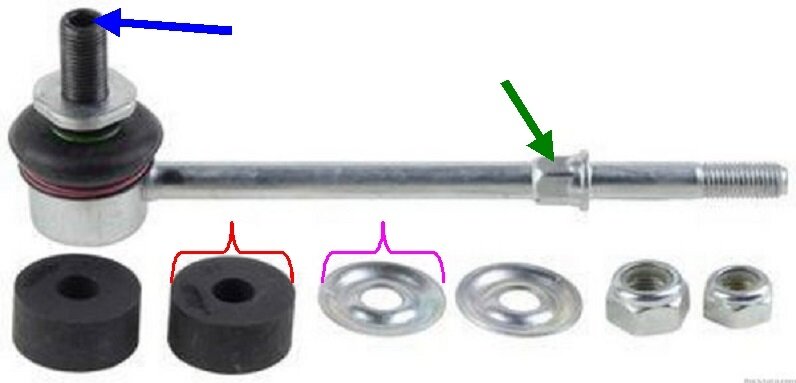

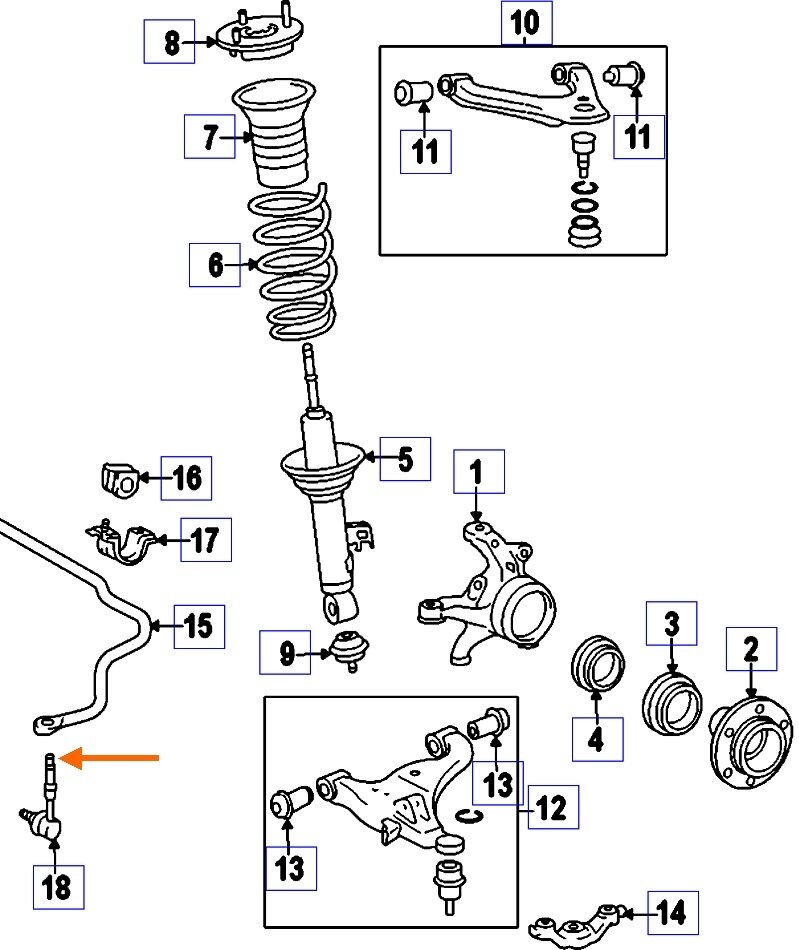

For your design, the job is not going to be much easier if you do both or if you loosen the other link. The photo below shows the kit you will get. First notice near the end of the threaded shaft on the right, there's a hex nut, (green arrow), to allow you to hold the link from spinning when you remove the nut. You'll need that hex if the ball and socket on the other end has come apart, otherwise, that other end will hold the stud from spinning. Sometimes that top nut gets rusted so tight, you end up rounding it or that hex off. If that happens, the fastest solution is to use an air-powered cutoff tool to cut through the nut, then crack it off.

On the other end, the blue arrow is pointing to a six-sided hole to insert an Allen wrench to hold that stud from spinning as you turn the nut off. One word of warning here. If you live in an area like I do in Wisconsin where they throw a pound of salt on an ounce of snow, that nut is also going to be rusted tight. Often we just start with the cutoff tool because we know what frustration that rust causes. If you are able to use an Allen wrench, be sure it is not a cheap dime store tool, and be sure it fits snugly. That will reduce the chances of the hole or tool rounding off. It can take a lot of elbow grease to get that nut off.

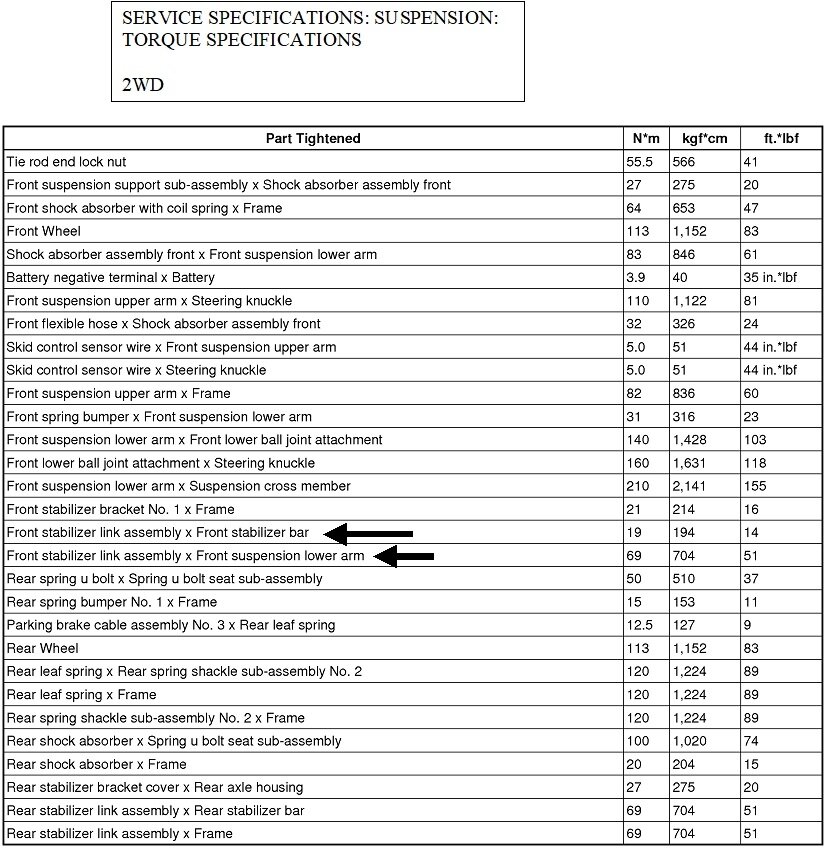

One of the most common mistakes made by competent do-it-yourselfers occurs when tightening the nut at the end of the anti-sway bar, (orange arrow in the fourth drawing). The specs call for 14 foot-pounds which is plenty, but very difficult to measure in a confined space. Instead, with all bushings of this type, tighten the nut just enough until the rubber bushings squish out to match the diameter of the metal washers, and no more. (Red bracket diameter should match the diameter of the purple bracket in the first photo). Often people, including inexperienced mechanics, will run those nuts as tight as they can get them by hand. That smashes the bushings so tight that they have no flex left as the suspension travels up and down. That leads to very early failure of those bushings, and then a rattle. You'll often find the same stud and bushing design on shock absorbers. When the bushings have expanded to match the diameter of the washers, the nut will not be fully tightened yet.

Now that I described that warning, it may not apply to your links. Normally that threaded section is over twice as long as needed to allow the part to be used on a lot of different brands and models. Notice on your links that threaded section isn't very long. The nut may indeed bottom out and then allow you to tighten it to 14 foot-pounds. My recommendation is to tighten the nut to specs unless you see the bushings expand to a larger diameter than the washers, then stop at that point.

Images (Click to make bigger)

Sunday, November 27th, 2022 AT 3:57 PM