An automotive suspension shock absorber is a normal maintenance item which requires replacement at regular intervals and can wear prematurely due to road conditions. There are many options when choosing a replacement shock or strut, its recommended to use top quality replacement parts to avoid premature failure. Most high grade shocks are gas filled to further improve the vehicle ride characteristics. When a shock absorber fails, a vehicle will continue to oscillate up and down after hitting a bump.

Let's Jump In!

Step 1 - Before removing a shock absorber its important

to know that a shock limits the downward travel of the suspension. Start by relieving

the tension of the suspension by positioning a jack under the lower ball joint or

control arm while raising the jack upward slightly. Not performing this step can

make shock replacement difficult as the weight of the suspension can hold the mounting

bolts from being removed.

Step 2 - Once the suspension tension has been relieved,

remove the lower shock mounting bolt.

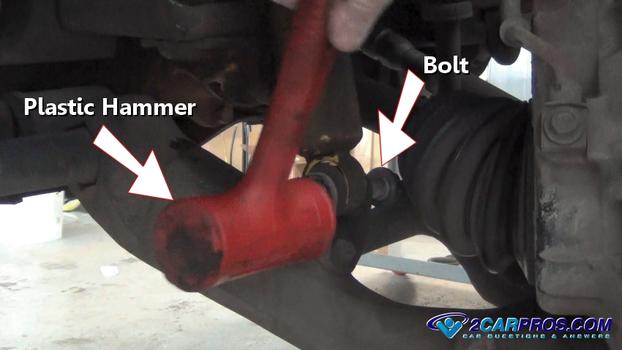

Step 3 - A plastic hammer or block of wood and a regular

hammer can help push the bolt through if it can't be removed by hand.

Step 4 - Use WD40 or equivalent to lubricate the shock

top mounting nut.

Step 5 - Slide a normal wrench over the top of the shock

stud and place it securely onto the mounting nut.

Step 6 - Adjust a crescent wrench to hold the top of

the shock stud to prevent the shaft from turning while using the wrench.

Watch the Video!

Please watch this video of the job being done, then continue down the guide to glean additional helpful information.

Step 7 - While holding the shock shaft with the crescent

wrench, turn the nut counterclockwise to loosen.

Step 8 - Once all mounting nuts and bolts have been removed,

grasp the shock and remove it from the suspension.

Step 9 - After the shock has been removed, match

the old shock to the new unit to ensure a proper installation. Confirm the top insulator

(bushing) is installed correctly.

Step 10 - After the new shock has been matched

to the old unit, gently install the new shock into the upper mounting bracket while

confirming the upper isolator position.

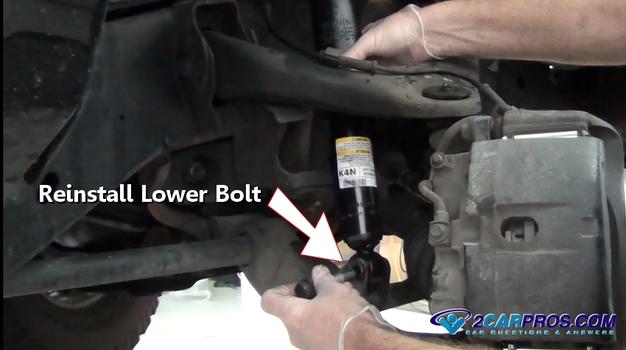

Step 11 - While holding the shock in place, install

the lower mounting bolt into place.

Step 12 - Once installed, use a wrench to hold

the nut tight while turning the bolt clockwise until tight.

Step 13 - After the shock is positioned, install

the upper part of the shock insulator set. This step is important for the shock

to operate without abnormal noises, ie. popping, rattling and banging.

Step 14 - When installing the upper nut, avoid

cross threading by winding the nut on by hand.

Step 15 - Use a crescent wrench to hold the shaft

from turning while tightening the upper mounting nut. ( Note: This nut needs to

be fairly tight to load the insulator correctly.)

Step 16 - After all mounting bolts and nuts are

tight, lower the hydraulic jack.

Step 17 - Anytime oil is leaking from a shock or

strut it has failed and replacement is required.

Questions?

Our certified technicians are ready to answer shock absorber questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.