Introduction

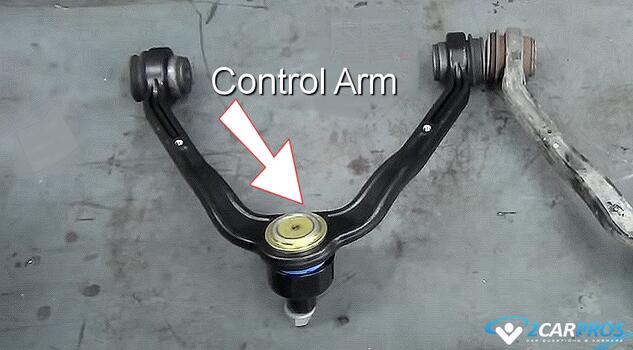

Non strut vehicles are designed with a suspension upper control arm that supports the top of the steering spindle. Much like a lower control arm it is responsible for controlling the vehicle while acting as a hinge that allows the tire to move vertically. This arm also houses the control arm bushings and upper ball joint, which enables the spindle to turn in either direction when the steering wheel is being used.

Tools and Materials Needed

- Jack and jack stands

- Wheel chocks

- Lug wrench

- Socket and wrench set

- Torque wrench

- Ball joint separator tool (pickle fork)

- Hammer

- Penetrating oil

- Replacement upper control arm

- Grease (if applicable for new components)

- Shop gloves and safety glasses

- Shop towels

Upper Control Replacement Guide (Front)

Before starting the repairs, park your vehicle on level ground and the set the emergency brake. Then, lift the car safely using jack stands, you will also need to remove the wheel and then reinstall it. Apply penetrating oil to the nuts and bolts needed for removal.

1. Support the Spindle: Position a floor jack under the lower ball joint or control arm to relieve downward pressure on the suspension components. This will enable you to remove the upper control arm without pressure bearing down on the arm. You might need to remove the ABS wheel speed sensor wiring or brake flex hose clips to free up the arm for removal. In some applications you might need to remove the shock before the arm can be removed as well.

2. Undo the Upper Ball Joint: After removing the cotter pin (if equipped) use a 18mm wrench (size may vary) to loosen the ball joint nut about 3 turns. Do not remove the nut completely because it will protect the upper ball joint threads during removal. Insert and wedge a large pry bar between the upper control arm and spindle while pushing downward to apply pressure to the upper ball joint taper fitted stud.

While holding pressure on the ball joint strike the spindle bulkhead with a hammer. You will hear a pop meaning the taper fit stud has been released from the spindle, once the taper fit has been released finish removing the ball joint nut. Lift the arm from the spindle. Use caution if any rubber brake lines are involved when the spindle comes loose and remove the line mounts if needed.

3. Remove Upper Control Arm Bushing Bolts: Mark the alignment adjusters using a felt pen and reference these marks when reassembling. Other designs will use a shim or a series of shims which must be reinstalled as they were removed. Use a 18mm wrench or socket (size may vary) to loosen and remove the nut on either side of the arm.

4. Remove the Upper Control Arm: After both nuts have been removed, slide the bolts from the control arm mounts while keeping the adjusters in order. To remove the control arm use a upward motion on the arm while pulling outward.

5. Install the New Upper Control Arm: Once the control arm has been removed match it against the old part to ensure a proper installation. Some control arms are designed using Zirk fittings to allow lubricant (grease) to be injected. Install the fitting and tighten it using an 8mm wrench. Install the new control arm into the frame mounts. This might take some doing while moving the arm up and down and pushing inward to line up the mounting bolts.

While aligning the bolt holes, install both mounting bolts in the same position as they were removed. Use a wrench or socket to tighten the both mounting bolts while keeping the alignment adjusters or shims in place. These bolts might be difficult to get a torque wrench on, but you want to tighten these bolts to manufacturer's specifications which are usually between 65 and 75 foot pounds.

6. Reconnect the Upper Ball Joint: Insert the upper ball joint into the upper spindle bulk head. Use a hammer to gently tap the taper fit stud into place which will keep the stud from turning while installing the nut, alternatively you can apply downward pressure. Install the upper ball joint nut by hand to avoid cross threading, use a wrench to tighten the upper ball joint mounting bolt. Use a socket and a torque wrench to tighten the nut to manufacturer's specification which is usually between 60 and 70 foot pounds, install a new cotter pin (if applicable).

Reattach any brake line, wiring holders or clips removed in the repair. Once the job is complete lube the upper ball joint using a grease gun. lower the hydraulic jack and reinstall the wheel and you are all set!

Conclusion

When driving the car for the first time listen for strange noises indicating the job will need to be rechecked. It is strongly suggested to have the car aligned when the suspension work is done.

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel for additional car repairs.