When working on your car you will need to learn how to use a floor jack. While doing your own repairs and services please follow these repair and service guides to help get your started. Make sure to have a high quality jack stands, after all it is holding up the car while you are underneath it.

Let's Jump In!

Let’s get started by jacking up and lifting your car the proper way. The first

step in this process is to lift the anvil of the jack stand while working the adjustment

lever this will show you how they work. Once the desired height is achieved push

the lever down to lock the top in place. To re-adjust the top, lift the lever to

free up the top and then once again lock it back down. To prevent failure never

use old rusted or cracked stands.

Next, inspect the lifting plate, this is what will be contacting the vehicle

to raise it off of the ground so make sure it is free from grease oil and dirt.

One important note here is never use a block of wood or any other material between

the lifting plate and the vehicle frame, as this object will have a tendency to

slip out and could cause problems, metal on metal is the preferred method.

The metal wheels are important and you should make sure they are in good condition

because once the vehicle’s weight is on the jack it will have a tendency to roll

slightly as the vehicle raises up. If the wheels are stuck use WD40 are other lubricates

to loosen them, if the wheels are missing or broken replace the wheels or get a

new unit, check all four wheels.

The next piece you need to know about is the handle, this handle controls the

up and down movement. To make the jack go up the handle must be turned clockwise

to tighten the fluid valve in the internal hydraulic pump. To have the unit go down,

loosen the valve by turning the handle counterclockwise. Once you have it positioned

under the car I will give you more instructions on the do's and don'ts of the operation,

but these are the basics.

This is the valve U joint, when you turn the handle this joint turns as well

which is connected to the handle. Sometimes the handle is not completely engaged

so there is no connection between the two. If you have tightened or loosened the

handle and nothing has happened, check to make sure this U joint is rotating with

the handle, if not, re-secure the handle down into the bulkhead, you may need to

loosen the bulkhead/handle set screw. The opposite end of the U joint is connected

to the hydraulic pump valve which controls the fluid flow and the up and down movement.

Now that we have a good idea on how it works let's test it. First close the valve

by turning the handle clockwise until tight. Next push the handle down repeatedly,

this will cause the lifting plate to rise with each pump of the handle. If when

the valve is tight and the lifting plate will not rise up while you are pumping

then it's either broken or low on hydraulic fluid. To check the fluid level, locate

the fluid fill plug (usually at the rear of the hydraulic pump or near the U joint)

and remove it, then add hydraulic oil or automatic transmission fluid works well

as well. You will need a small funnel or tube to connect to the container to add

fluid.

Before you begin raising your vehicle you must install wood blocks to the wheels

of the opposite end of the vehicle being lifted. This is because if you raise the

vehicle by the wheels that are keeping the vehicle from rolling such as the rear

wheels on a rear wheel drive vehicle, the vehicle will want to move on you because

the tires that were holding it in place are now off of the ground and the front

wheels will let the vehicle roll freely. Pay attention to the drive wheels or the

emergency brake wheels to help hold the vehicle in place.

Now you know how the floor jack works and how to block the wheels. It is time

to know where to and where not to place the jack stands when holding the vehicle

once lifted. In the picture below it shows safe places which are shown by the blue

dots and the arrow shown. The left blue dot near the control arm works well when

you are just removing one tire, if you are lifting the complete front end of the

car the right dot works best. The arrow also works well to raise one side of the

vehicle.

Watch the Video!

Please watch this video of the job being done, then continue down the guide to glean additional helpful information.

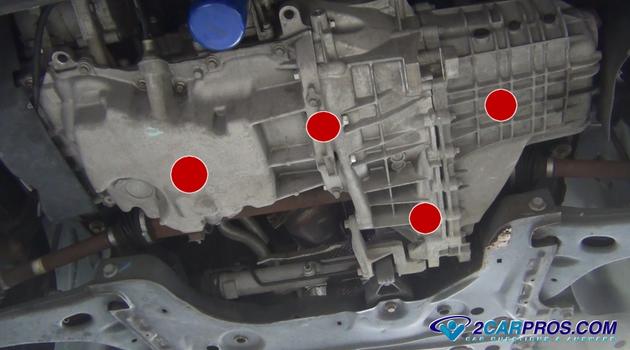

There are a lot of places that you can do damage to your vehicle when jacking

it up, be sure you NEVER place the lifting plate on the engine or transmission (red

dots) to raise the vehicle. To add to this list: fuel lines, emergency brake cables,

CV axles, drive shaft, exhaust system and suspension components such as control

arms and sway bars will cause damage.

Here is another example of where NOT to place the lifting plate, on plastic covers,

these covers are held in place usually by flimsy metal which holds the radiator

and air conditioner condenser and can be easily damaged by the force of the jack.

In general if you hear a crunching sound when lifting the vehicle up, it’s causing

damage, once you learn where and where not to lift from you will be able to spot

safe places more easily.

On uni-body vehicles there will be a front frame bulkhead which is the strongest

place to lift the vehicle, there is a bulkhead on each side. Some vehicles will

have an arrow or markings to indicate where to place the jack. Trucks, SUV's and

larger vehicles will have a more pronounced frame which will be easy to see and

is where the floor jack’s lifting plate should be placed. It takes a little bit

of practice, but once you get the hang of it you will be able to instantly locate

these safe spots to place the lifting plate.

Every vehicle is constructed and welded at the bottom edge which connects the

body to the bottom plate of the vehicle. This pinch molding as they call it, is

welded together at the factory and provides a great place to lift the vehicle from.

Never lift the vehicle from the running boards or side steps on SUV's and trucks.

If you are still not sure where to lift the car from, check the diagram on the

vehicle’s spare tire jack, or in the owner’s manual which is normally located in

the glove box. This will give you specific places to lift the vehicle from.

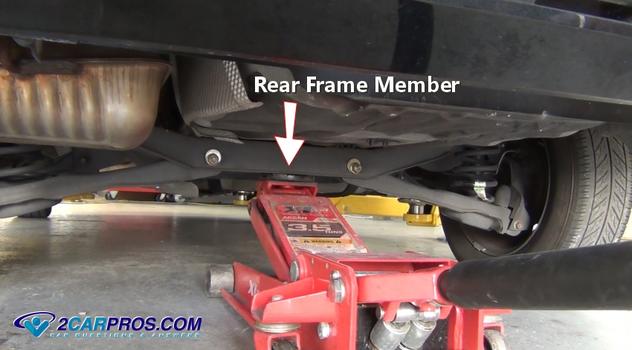

To lift the rear of the vehicle up to work on the rear brakes, shocks, fuel or

EVAP system etc., locate the rear frame member for front wheel drive car’s. Position

the lifting plate directly under this frame, tighten the handle and start to pump

until contact is made, be sure the lifting plate is centered on the frame, this

will help it become more secure while lifting. Do not add wood blocks, these can

break and split, causing problems, metal on metal is the safest way.

On rear wheel drive vehicles and trucks the center of the differential is the

safest place to raise the vehicle from. Center the lifting plate directly under

this point to raise the entire rear of the vehicle. This position works on both

straight axle and independent rear suspension vehicles.

This is how the vehicle should look when properly lifted and secures with jack

stands. There is no need to remove the hydraulic jack, you can just leave it there

if it’s not in the way while work is being done such as replacing brakes. NEVER

GET UNDER A CAR WITHOUT JACK STANDS! A vehicle is very heavy and trusting the floor

jack alone is not wise.

Once the front is lifted, position and adjust the jack stands under the main

frame, bulk head or pinch welds of the vehicle. Here’s a great safety tip; when

you are working on a job that includes removing the tires, after you have removed

them lay them down flat under the vehicle, this will give an added layer of protection

against the vehicle falling all the way down to the ground.

This is how the front of the vehicle should look when lifted and secured with

jack stands, much like the rear of the vehicle, leave the floor jack under the vehicle,

as long as it doesn't get in the way of the repair or service being performed.

Once the job has been completed it’s time to lower the vehicle down. First raise

the vehicle up and off of the stands then remove the stands and slowly lower the

handle completely and slowly turn the handle counterclockwise. This can take some

practice because if you loosen the handle too quickly the vehicle will drop abruptly;

the best practice is to lower the vehicle slowly. The reason for the handle being

low is to avoid contact with the vehicle when it’s being lowered down. You are all

set better informed about how to raise and lower a vehicle then most, I hope you

enjoyed this article and video please visit use anytime we are here to help you

fix your car right.

Questions?

Our certified technicians are ready to answer floor jack questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.