Hello

Thanks for the donation.

I am going to post the replacement procedures for the 2.2L engine model's head gasket(s). I can post specific pictures and procedures for your engine size if it is different than the 2.2L engine. Just let me know..

REMOVAL:

Disconnect the negative battery cable.

Remove the drive belt.

Remove the power steering pump, alternator and bracket.

Remove the valve rocker cover.

Tag and disconnect the PCV hose and spark plug wires.

Remove the connector bracket attaching bolt.

Remove the crank angle and cam angle sensors.

Disconnect the oil pressure switch. Remove the knock sensor.

Disconnect the blow-by hose.

Relieve the fuel system pressure and disconnect the fuel pipes.

Remove the intake manifold and gasket. Remove the water pipe.

Remove the timing belt, camshaft sprocket and related components.

Remove the oil level gauge guide attaching bolt on the left cylinder head.

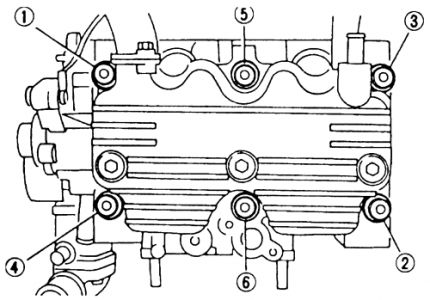

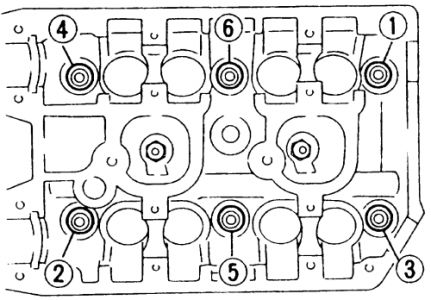

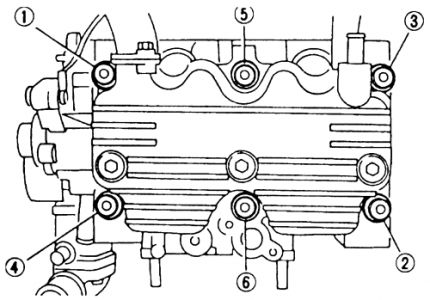

Remove the cylinder head bolts in the proper sequence. Leave bolts 1 and 3 installed loosely to prevent the cylinder head from falling.

Separate the cylinder head from the block, Use a plastic-faced hammer, if needed, to separate the head from the cylinder block.

Remove bolts 1 and 3. Remove the cylinder head and gasket.

Clean all gasket material from both mating surfaces.

(((Cylinder head bolt loosening sequence-2.2L engine)))

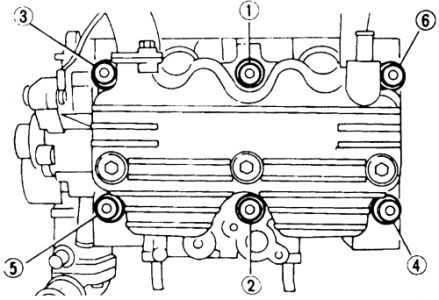

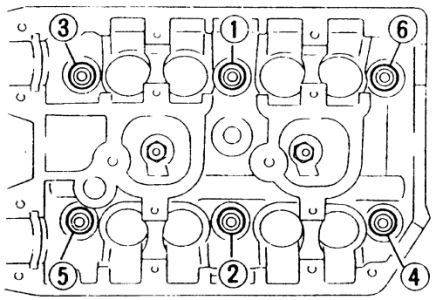

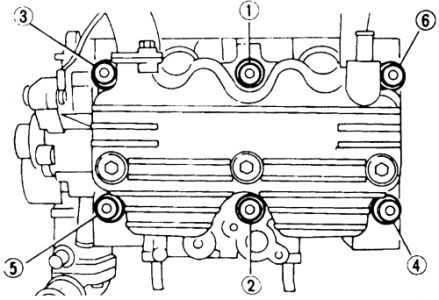

(((Cylinder head bolt tightening sequence-2.2L engine)))

INSTALLATION:

Inspect the cylinder head for warpage. Warpage should not exceed 0.0020 in. (0.05mm).

Install the cylinder head on the block using a new gasket. Secure in place with the mounting bolts. Coat each bolts with clean engine oil, and hand-tighten.

Tighten the cylinder head bolts to the following specifications:

Tighten all bolts in sequence to 22 ft. lbs. (29 Nm).

Tighten all bolts in sequence to 51 ft. lbs. (69 Nm).

Loosen all bolts by 180 °, then loosen an additional 180 °.

Tighten bolts 1 and 2 to 25 ft. lbs. (24 Nm) for non-turbo engines and 27 ft. lbs. (37 Nm) for turbo engines.

Tighten bolts 3, 4, 5 and 6 to 11 ft. lbs. (15 Nm) for non-turbo engines and 14 ft. lbs. (20 Nm) for turbo engines.

Tighten all bolts in sequence 80-90 °.

Tighten all bolts in sequence an additional 80-90 °.

Do not exceed 180 ° total tightening.

Install the oil level gauge guide attaching bolt on the left cylinder head.

Install the timing belt, camshaft sprocket and related components.

Install the water pipe.

Install the intake manifold and tighten bolts to 21-25 ft. lbs. (28-34 Nm). Connect the fuel delivery pipes.

Connect the blow-by hose. Install the knock sensor.

Connect the oil pressure switch connector.

Install the crank and cam angle sensors.

Install the connector bracket attaching bolt.

Connect the spark plug wires. Connect the PCV hose.

Install the valve rocker cover and tighten bolts to 4 ft. lbs. (9 Nm).

Install the alternator, power steering pump and accessory drive belt.

Connect the negative battery cable. Start the engine and allow it to reach operating temperature. Check for leaks.

Let me know if you need further assistance..

Thanks for using 2CarPros.com!

Friday, February 13th, 2009 AT 7:31 PM