Hi and thanks for using 2CarPros.

When it fails to start, I need you to check for spark and fuel to the engine. One will be missing and I feel it may be spark. Here are two links that show in general how to check both:

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

https://www.2carpros.com/articles/how-to-test-an-ignition-system

Now, if you find there is no spark, I suspect the crank angle sensor may be bad. Look through this link:

https://www.2carpros.com/articles/symptoms-of-a-bad-crankshaft-sensor

If you find no spark when it fails to run, that is my first suspect. However, the crank angle sensor on your truck is in the distributor. Here is the description of the ignition system.

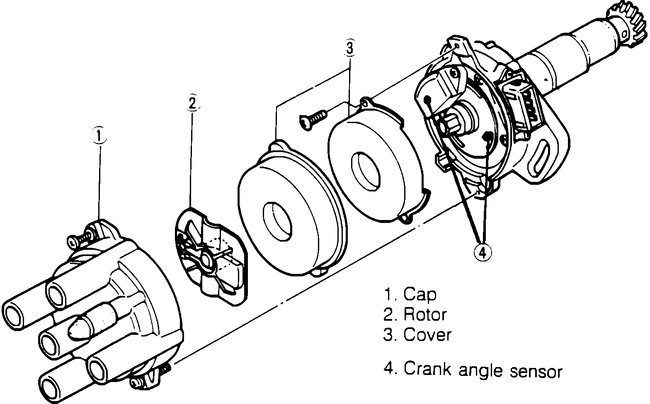

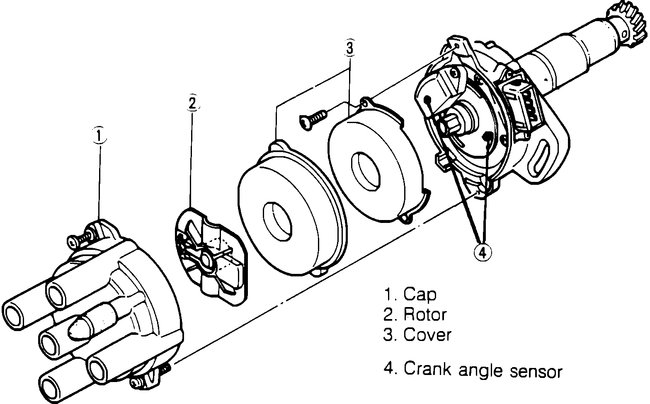

The distributor, mounted to the left front side of the cylinder head and driven by the camshaft, directs high voltage ignition coil output to the spark plugs in proper sequence (firing order). To accomplish this, a rotor on the driven shaft acts as a rotary contact, directing ignition coil voltage to each spark plug terminal as it turns inside the distributor cap.

The distributor utilizes a photo-diode type crank angle sensor consisting of a slotted disc that turns with the distributor shaft and a stationary pick-up assembly. As the disc rotates past the pick-up, the slots (one for each cylinder) alternately pass and block photo-diode light transmission. Signals generated are interpreted by the ECU to determine crank angle (#1 cylinder TDC) and engine rpm. To calculate ignition timing, the ECU uses this input together with several others related to vehicle operating conditions. Except for the initial setting, ignition timing is under ECU control.

_____________________________-

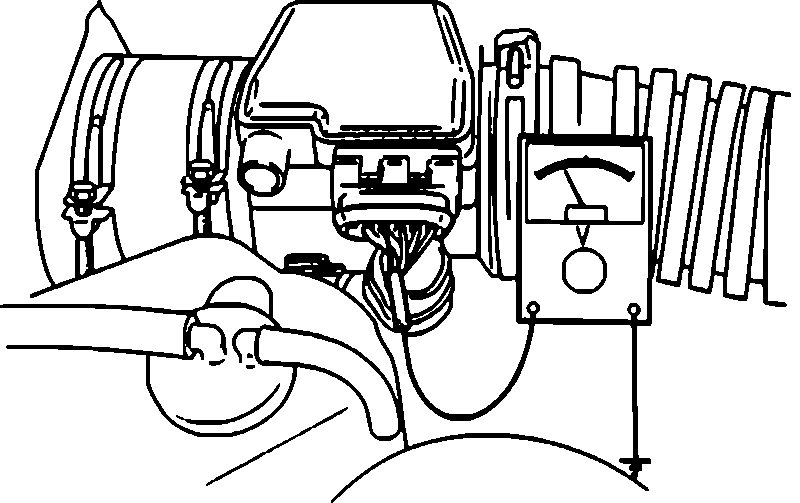

I attached a picture of the distributor assembly. Next, I suggest checking for diagnostic trouble codes. Although this is an OBD1 system, it still can be checked. Go to this site:

https://www.2carpros.com/articles/diagnostic-trouble-codes-for-1995-and-earlier-mazda-cars-obd1

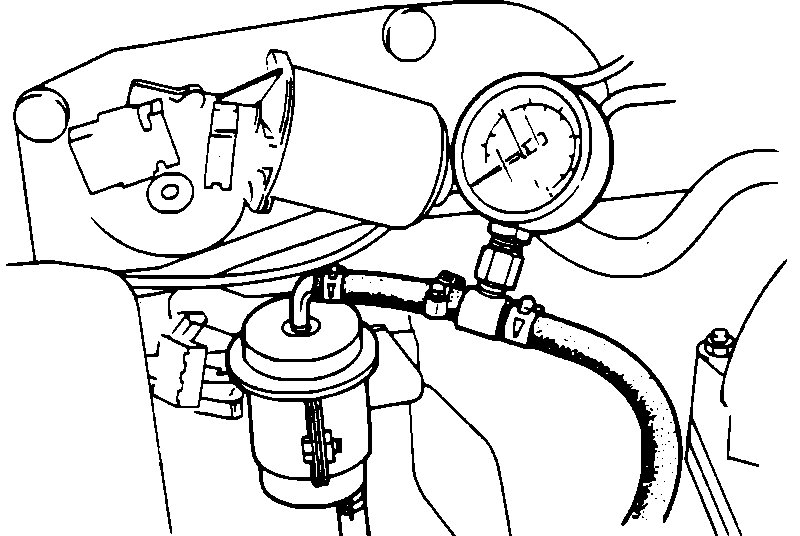

Also, here are the directions specific to checking fuel pressure on your truck. Also, the fuel specs are included in the steps. The last two pics correlate with these directions.

FUEL PRESSURE TEST

1. Relieve fuel system pressure by starting engine with fuel pump relay (circuit open relay) disconnected and let run until engine dies, then slowly and carefully remove hose on outlet side of fuel filter. Cover with a clean rag while removing hose, to avoid spraying fuel in your face.

Checking Fuel Pressure

2. Using an extra piece of injector hose, connect fuel pressure gauge as shown in illustration.

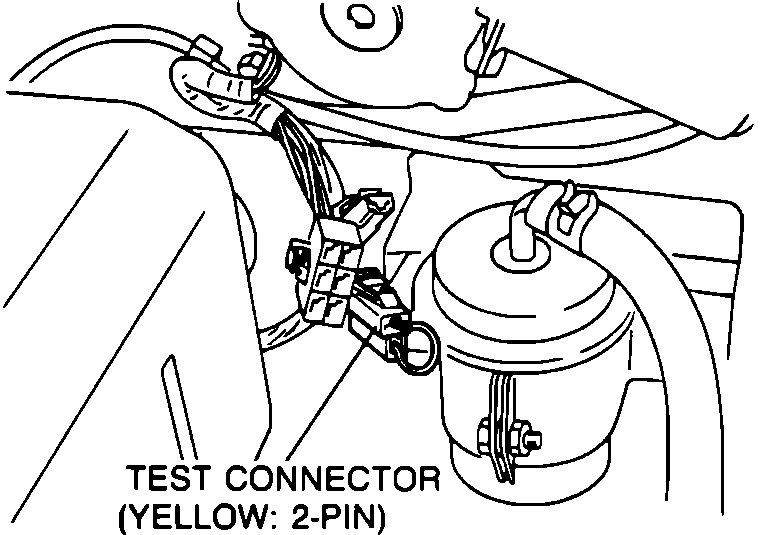

Fuel Pump Test Connector

3. Energize fuel pump by bridging the terminals of the yellow fuel pump test connector (located near the firewall below the windshield wiper motor, see illustration) and turning ignition "ON" .

4. Pinch off hose between gauge and pulsation damper with a clamp.

5. Observe fuel pressure on gauge (this will be the maximum fuel pressure available from the fuel pump).

64 - 85 psi (441 - 589 kPa)

If pressure is higher than the maximum specified, replace fuel pump. If pressure is lower than the minimum specified, check fuel filter. If filter is OK, replace pump.

6. Disconnect jumper wire from test connector and turn ignition "OFF". Wait 5 minutes, then observe fuel pump residual pressure on gauge.

Minimum 50 psi (343 kPa)

If residual pressure is less than specified, fuel pump pressure relief valve is leaking - replace pump.

7. Remove pinch clamp from hose between gauge and pulsation damper.

8. Start engine and let idle.

9. Observe fuel pressure on gauge (this is the system operating pressure).

28 - 37 psi (196 - 255 kPa)

If pressure is higher than the maximum specified, check fuel return line for kinks or restriction. If pressure is lower than the minimum specified, check fuel filter. If filter and return line are OK and pressure is still not within the specified range, replace pressure regulator.

10. Disconnect vacuum hose from fuel pressure regulator with engine idling.

Fuel pressure should increase when vacuum hose is removed.

38 - 46 psi (265 - 314 kPa)

If not, replace pressure regulator.

11. Shut engine "OFF" and wait 5 minutes, then observe residual pressure on gauge.

Minimum 21 psi (147 kPa)

If not, check for leaking fuel injectors. If injectors are not leaking, replace pressure regulator.

If all test results are OK, fuel pump and pressure regulator are OK.

_______________________________________________________

Let me know if any of this helps or if you have questions.

Take care,

Joe

Images (Click to make bigger)

Wednesday, December 12th, 2018 AT 7:49 PM