You don't need a code reader to check the fault codes. Chrysler made doing that yourself much easier than any other manufacturer. Cycle the ignition switch from "off" to "run" three times within five seconds without cranking the engine. Leave it in "run", then watch the code numbers appear in the odometer display. You can go here:

https://www.2carpros.com/trouble_codes/obd2/p1500

to see the definitions, or I can interpret them for you.

Also be aware diagnostic fault codes never ever say to replace a part or that one is bad. They only indicate the circuit or system that needs further diagnosis, or the unacceptable operating condition. When a sensor like the throttle position sensor, or other part is referenced in a fault code, it is actually the cause of that code about half of the time. First we have to check for wiring and connector terminal problems, and mechanical problems associated with that part.

You're correct that the sensors you listed won't cause stalling. The throttle position sensor has about the least impact on fuel metering calculations. It's the oxygen sensor that concerns me. Its main function is to provide information so the Engine Computer can fine-tune the air / fuel mixture. What worries me more is of the over 2,000 potential fault codes, about half of them refer to things that could adversely affect emissions, as is the case with O2 sensors, and those are the codes that turn on the Check Engine light. While oxygen sensor codes could be relatively minor, with the warning light already on, you'll never know if a more serious fault code is set. You won't know it so it's going to be ignored. That could lead to more serious problems.

To add to the misery, there is always a long list of conditions that must be met for the computer to set a fault code. One of those conditions is that certain other codes aren't already set. The easiest example to explain involves the coolant temperature sensor and the intake air temperature sensor. The Engine Computer knows that after the engine has been off for at least six hours, both sensors had better be reading the same temperature. Failures of temperature sensors are extremely rare because they have just one component inside them. Instead, most fault codes related to them involve the wiring and their connectors. If you were to unplug, lets say the coolant temperature sensor, with the ignition switch on, the computer would see that, set the appropriate fault code, and stop using it as a reference for the intake air temperature sensor. Serious defects with the IAT circuit will still be detected, but the more minor tests the computer constantly runs will be suspended since there's nothing trustworthy to compare it to.

It's not until the coolant temperature sensor circuit is repaired that the air temperature sensor tests will resume. That is when any minor problems that developed recently will finally be detected. In the case of your oxygen sensor, one example it's used for is when the computer commands the charcoal canister purge valve to open, it expects to see a rich condition reported by the front O2 sensor. With no valid readings from the O2 sensor, the computer has no way of verifying the purge valve opened as instructed. The rubber hose could be plugged, or dry-rotted and leaking, but you'd never know.

There's a more direct way the oxygen sensor can be involved here. Depending on how the previous owner hacked the wiring to it, if the wire for the sensor's heater circuit fell down onto hot exhaust parts, it could short to ground intermittently. That harness falling down is already a somewhat common problem on many car and truck models. With a direct short, a fuse will blow, then the engine can't be restarted until that fuse is replaced. With rusty exhaust pipes, the short might not be solid enough to cause the fuse to blow, but it can drag circuit voltage down enough to cause other parts of it to stop working. The O2 heater circuit is tied in as part of the "ASD", (automatic shutdown) relay circuit that also feeds the injectors, ignition coil(s), alternator field, and fuel pump or pump relay.

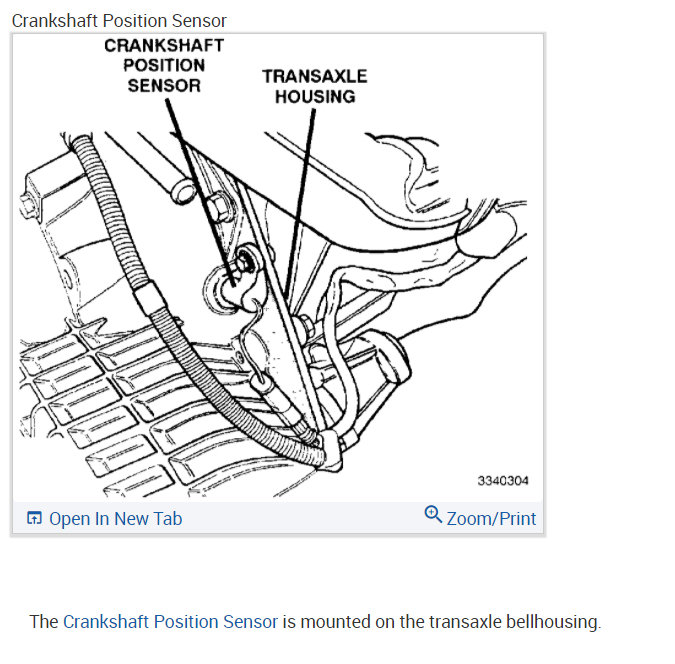

Now that I described what could happen, we have to figure out what is happening. We know fuses aren't being blown. We know some defects that could provide valuable information aren't going to be detected. Based on your ability to restart the engine right away, we can probably rule out the crankshaft position sensor or the camshaft position sensor failing by becoming heat-sensitive, which is pretty common on all car brands.

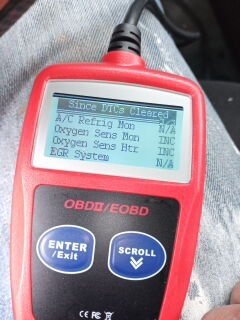

Depending on what you have for equipment, there's two things I would do if this was happening to one of my vehicles. The first is to connect a scanner so I can view live data. I have a Chrysler DRB3 for most of my vehicles. Under the "Inputs / Outputs" menu, it lists the crankshaft position sensor and the camshaft position sensor as "Present" or "Lost". Aftermarket scanners may list them as "Yes" or "No", or something similar to indicate those signals are showing up at the computer. Those signals will both still be present when the engine stalls, as long as it's still rotating as it coasts to a stop. What you need to watch for is if one of them switches to "Lost" while you're driving, and then the engine stalls a fraction of a second later. That can be hard to catch, so most expensive scanners have a "record" function that lets you capture about a five-second picture of sensor data. Since that data passes through the scanner's memory, the recording actually starts a couple of seconds before you pressed the button.

Another thing to look at is the state of the ASD relay, meaning "on" or "off", and what happened at the instant it turned off. If it switched to "off" on the recording, and then engine speed started to drop, it was switched off by the computer, usually in response to losing the cam or crank sensor signal. Instead, if you see engine speed slowly dropping to "0', and then the ASD relay switched off a couple of seconds later, it was likely due to loss of spark or loss of fuel pressure, but not both. This is easier to see on a scanner because as long as the truck keeps coasting at a high enough speed, the transmission and torque converter will keep the engine rotating, perhaps as long a five to ten seconds.

You can also get a better idea if either of these tests seems appropriate by observing how the stalling occurs. A fuel pressure problem will cause sputtering or gradual loss of power over a period of a up to a few seconds. With a spark-related problem, or if the ASD relay turns off, stalling will be instant, as if you had switched the ignition switch off.

Sunday, January 3rd, 2021 AT 4:47 PM