I have done the following over the years (some multiple times, some once. I do not currently drive the truck. It's been driven about 3,000 miles in 6.5 years):

1. Rebuilt engine with metal-backed timing chain guide (the motor mounts look fine)

2. Machined and rebuilt the cylinder head and adjusted the valve lash on intake and exhaust (cold and warm) = no change.

3. Installed all new vacuum hoses = no change.

4. Sprayed the vacuum hoses, intake manifold, etc with carburetor cleaner checking for changes in idle = Nothing.

5. New (installed years ago, but again, I barely drive the truck) spark plugs (NGK's, just like the 22REs like).

6. Recently checked the plugs for signs of engine health = they look fine/normal.

7. Put in 4 new Toyota OEM spark plug wires (no cheap wires) + ignition wire = No significant change.

8. Pulled each plug wire at the spark plug/engine = all 4 produced an engine stumble.

9. New distributor and cap (quality, not cheap) = No noticeable change.

10. New OEM TPS installed and meticulously adjusted via 4crawler. Com directions = slight power increase, slight idle improvement.

11. New transmission mount (old one was falling apart) = the shake at idle is less jarring but still as active.

12. New marine battery cables.

13. Tested VAFM while installed. It passed every test except for the last one. (Write-up of instructions are at 4crawler. Com) Not sure about the last test; waiting for outside input on replacing it because it's an expensive part.

14. R and R Oxygen sensor with OEM Denso sensor. Previous once was a Bosch which does not work well for the 22RE. New Denso sensor has produced a noticeable power gain, improved responsiveness, and the "rich" burning gasoline smell has been lessened; rough idle still present.

15. Pulled spark plugs again, checked and re-gaped them = small increase in power; idle still the same.

16. Checked for engine timing with sensor jumpered. It was coming in around 14 BTDC so I adjusted the distributor to get 5 BTDC. The distributor is NOT swung all the way to one side, rather it's pretty centered, so I don't think it's off a tooth but I don't have a tach so I can't check the idle RPMs. I'm going to buy a handheld one in the next week and re-check the timing.

17. Adjusted the valve lash on both intake and exhaust to spec listed on 22reperformance. Com.

18. Removed the charcoal canister and attempted to "clean" it. Improved airflow from bottom spout through top ones but not vice-versa. I'd noticed that there's a lot of off-gasing when I open my gas cap at all.

19. Oh yeah, the intake manifold was thoroughly cleaned when I rebuilt the engine. I also adjusted the stop screw for the accelerator cable (the one that goes from the throttle body to the accelerator pedal). I do need a new detent cable because it's completely overstretched.

I believe I have a misfire but I don't know what I should be hearing. I remember reading somewhere that holding a towel in front of the exhaust pipe should show a smooth flow and that the towel shouldn't be sucked in or be "puffing" back and forth like someone is blowing small puffs of air at it, repeatedly. No idea if that's true but a towel held there responds like small puffs are being blown at it.

I've had an injector replaced professionally which immediately produced a complete, overnight parasitic drain from the alternator. I've since fixed it after much hunting for the source. Nothing else has been done by anyone other than me in about 3 years.

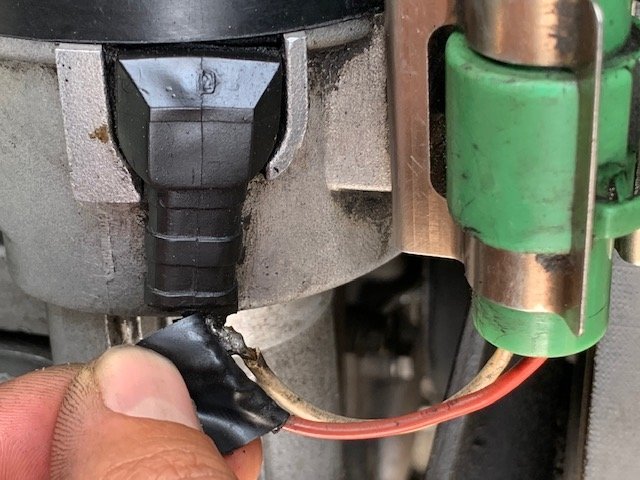

My next steps are to try to jiggle the intake connectors to see if the engine stumbles, do another timing adjustment once I get the handheld tachometer, test the pickup coil(s) and ignition coil(s), and I may also try spraying carburetor cleaner for leaks one more time.

I'm really wondering about the engine idle and timing. It seems to need to idle high (it sounds high/fast, but what do I know?) So it doesn't stumble. But I'm running out of things to do and need help. What am I missing?

Monday, September 7th, 2020 AT 5:33 PM