If you don't mind me sticking my nose in here, this is what we use, and to my knowledge, Chrysler is the only manufacturer that puts these tables in their service manuals. There isn't anything any easier. Ford has something similar in their "Electrical, Vacuum, Troubleshooting Manuals" (EVTM), but you have to look on multiple pages to find all the wires.

If you find these too hard to read, right click on a list, then click "Copy". Next, open a typing program on your computer like Microsoft "Word" or "Word Pad", then right click, then click "Paste". That program will have an option to expand it so you can read it easier.

As an alternative, Roy already went through the hard part of finding the drawings. Either of us can cut them in half, expand the parts, then repost them in a larger format, if that will help.

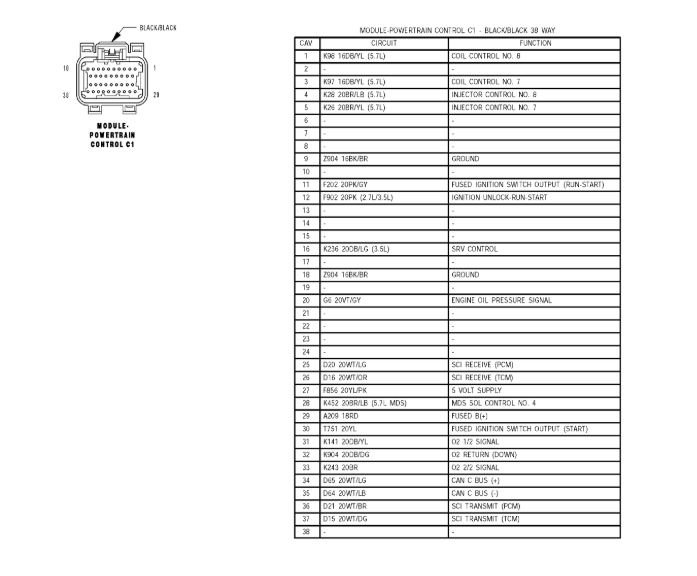

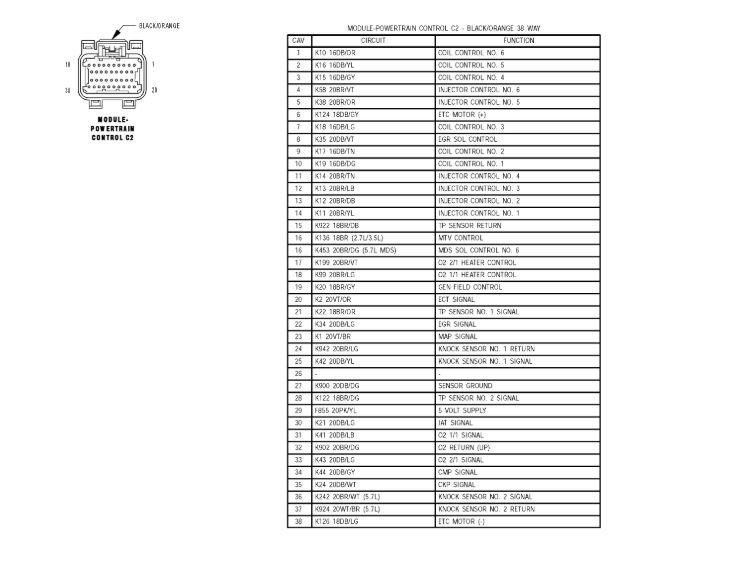

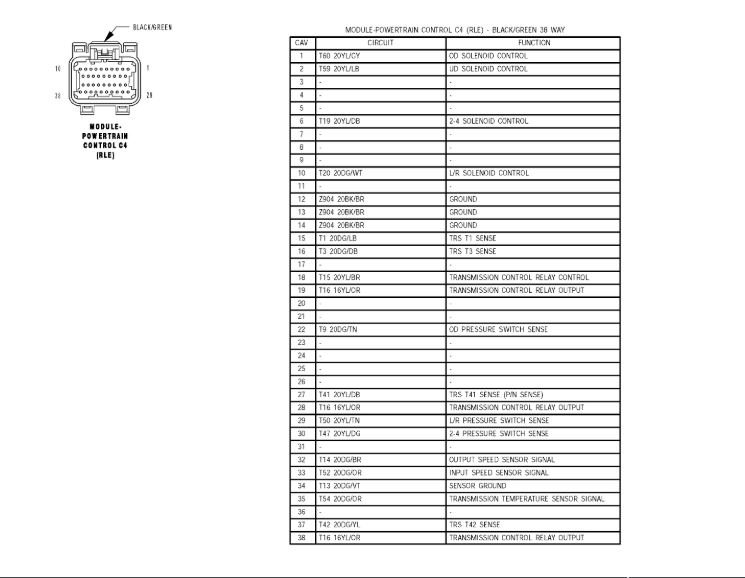

Each drawing shows a different connector with the color of its body, the number of terminals it can hold, and the shape of any key ways and latches built into it. You're looking at the terminal end of the connector body, not the end where the wires come out. In the first drawing, terminals 1, 10, 29, and 38 are pointed out in the four corners. You just count between them to find the other terminals.

Each terminal location is listed in the chart along with the wire color. Here's where some care is needed. The wire colors are usually pretty distinct, but the stripes, or "tracers" can be of two different but very similar colors. Watch out, for example, for light brown, yellow, or tan tracers that can look the same.

The wire listed for terminal # 1 is K96 16DB/YL. The "K" is for the type of circuit, and the "96" is just to show it's different from the others. You don't have to concern yourself with those. The "16" means it's a 16 gauge wire. What you're really asking about is the "DB/YL". That's dark blue with a yellow tracer. You need to find the dark blue / yellow wire and connect it to terminal # 1.

It sounds like you're making a lot of work for yourself by changing the plugs, or at least changing a lot of terminals. A better solution would be to snip the connectors, along with a few inches of wire, from a car in the salvage yard. Be sure they come from a car that had the same size engine. Rather than cutting and splicing every wire, if you have one that is good on your car, remove that terminal from the connector, then plug it into the replacement connector. All connectors have some type of locking wedge, or "pimento" as I call them, that has to be pried out. That allows you to use a small pick to lift a plastic finger, then you can pull the terminal out by tugging on the wire. Don't use a lot of force to pull a terminal out. If the finger is moved out of the way far enough, the terminal will slide right out. If the finger isn't moved far enough, no amount of tugging will get the terminal out. You'll just damage the finger or tear the wire off. Bending the fingers out of the way takes practice and patience, but it will be fairly easy once you get the hang of it.

Saturday, March 7th, 2020 AT 10:46 PM